Weidmuller: Custom PLC Interface Module Program for Industry 4.0 Applications

November 12, 2024

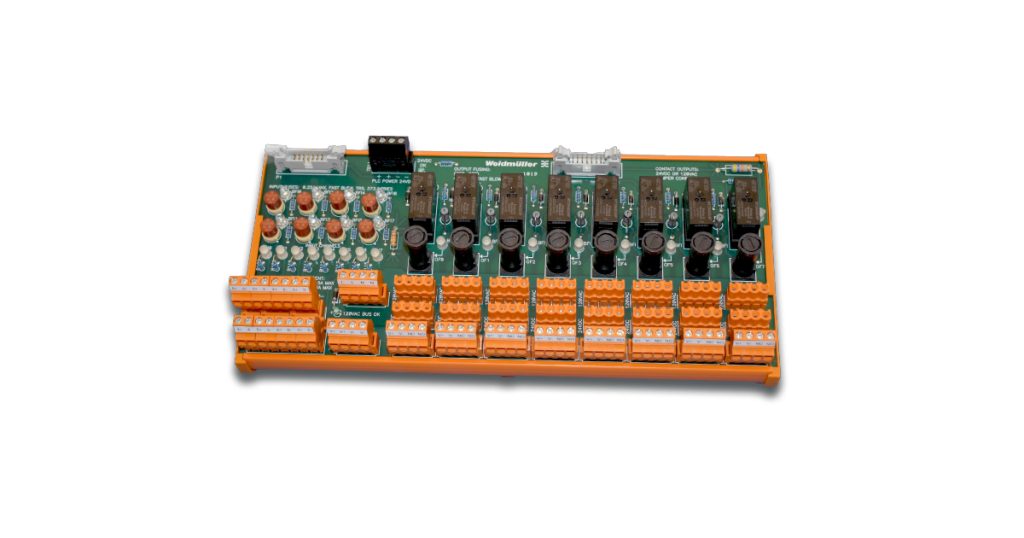

Weidmuller USA has recently launched its Custom PLC Interface Modules program to improve device and field connectivity in a wide variety of Industry 4.0 applications.

Designed to meet the specific application needs of a business, these new interface modules can be installed in control cabinets serving all industry sectors. In addition, Weidmuller offers complete engineering, prototype and production services for fully customized PLC modules.

In addition to the Custom PLC Interface Module program, Weidmuller USA’s Engineering and Assembly Services located in Richmond, Va. also offers manual and automated DIN rail assembly, modified and assembled enclosures and custom automation and PV combiner box solutions.

“If a company’s application requires certain complex features and functionality while maintaining a specific form factor, Weidmuller can design and deliver a fully customized module that interfaces directly with all PLCs at a business,” said John Froustet, Director of Device & Field Connectivity Division Americas at Weidmuller USA.

Froustet noted that the Custom PLC Interface Modules are assembled under one roof in the U.S. using Weidmuller components, providing the highest levels of quality assurance. “The U.S.-based engineering, development, quality control, assembly and warehouse location shortens the supply chain and streamlines the retrofit process,” he added.

Primary benefits of the Custom PLC Interface Modules include:

- Universal Connection Solutions – the comprehensive system offers connection solutions for all common PLC manufacturers

- Space-Saving – The compact PLC and DCS interface modules save valuable space in the control cabinet

- Time-Saving – Retrofitting without rewiring of sensors and actuators from the field level saves up to 95% in time requirements

- Flexible Customization – Weidmuller’s product offers the optimal solution for customer-specific interface assemblies