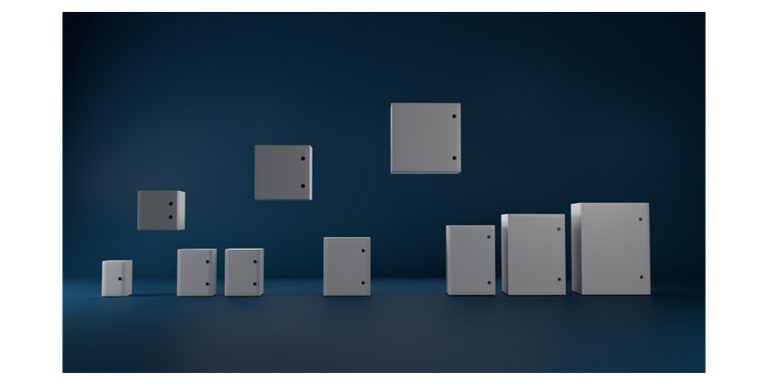

Custom NEMA Electrical Enclosures

January 12, 2024

Specializing in low volume, high mix, made-to-order solutions, NEMA offers an extensive array of over 1600 electrical enclosure options tailored precisely to your specifications.

Whether you require a single unit or a hundred, NEMA’s dedicated team is available to guide you seamlessly through the design and manufacturing journey.

To initiate the process, simply complete the request a quote form, specifying details such as height, width, and depth, along with material type, rating requirements, and certifications. Approval drawings will follow upon acceptance of the purchase order. Explore additional customization options, including cutouts, holes, louvers, swing panels, drip shields, window kits, and insulation. NEMA’s seamless customization services are integral to the build of the electrical enclosure.

Lead times typically range from 6 to 8 weeks, contingent on production availability and drawing turnaround time. If you’re in need of a faster solution, explore NEMA’s extensive selection of 1600+ standard electrical enclosures.

Some common customization features seen on a regular basis include:

- Enclosure sizes to your exact dimensional requirements

- Cutout and thru holes for mounting HMI’s, operator devices and conduit entries

- Gland plates on any or all 4 sides of the enclosure

- Welded half or full couplings

- Sunshields and roofs

- Insulation with or without metal retainers

- Vast array of hardware available from buckle latches, special keyed locks or ¼ turn latches.

- Customized mounting panels which can include drilled and tapped holes, pem nuts or studs in any material from powder coated steel, aluminum, or 304/316 Stainless steel

- Adjustable inner doors or swing panels

- Door on Door enclosures that allow access to HMI’s without opening the main enclosure door

- Specialty finishing including anodizing, electro-polishing or passivation

- Custom colors on powder coated enclosures

- silk-screening or chemical etching with your company brand or logo