AX Enclosures: Now Also Ready for Outdoor Use

January 26, 2021

Rittal is replacing its previous KS series with the new fibreglass enclosures AX and so completely redefining fibreglass enclosure technology. The development is based on Rittal’s technology for sheet steel and stainless-steel enclosures, which can be used to greatly simplify and speed up manufacturing processes in panel building and switchgear manufacturing. Now, for the first time, fibreglass enclosures also feature this system technology. This is a win-win situation for plant constructors: The result is an enclosure technology permitting the greatest possible simplification, speed and design freedom while at the same time fulfilling every precondition for maximum safety and robustness. Regardless of whether safely located in a factory building or exposed to the wind and the elements, the new fibreglass enclosures AX can withstand all extremes.

More reliability

The new enclosures are fully suited for outdoor use thanks to a fibreglass that is reinforced with glass fibres and which has a seven times higher UV resistance. For this reason, they have a UL F1 outdoor rating (UL 746C). An integrated rain protection strip on the upper and lower edges of the door, which protects the gasket against dust and rainwater, means that the enclosure is doubly sealed. The Class II protective insulation for up to 1000 V AC ensures increased personal protection. The protective insulation and the high protection categories of up to IP66 or NEMA 4X remain intact even the enclosure is populated. Thanks to the intelligent enclosure design, interior installation is unproblematic and does not affect the encapsulated enclosure area. The enclosure is also UL 508A approved and has UL94 fire class V-0.

Improved efficiency

Panel builders benefit right from the start, thanks to a sophisticated enclosure concept. Speedy assembly is ensured by the presence of numerous mounting bosses inside the housing. These enable accessories such as punched sections and rails to be quickly and directly screw-fastened to any enclosure interior and to the rear panel. Door-operated switches and door stays can also be directly attached to the mounting bosses. What is more, top-hat rails can be screwed directly onto the existing mounting bosses anywhere within the enclosure. The mounting plate can be easily screwed from the front using the pre-assembled bolts and it can also be earthed later via the existing keyholes. Moreover, the door hinge can be simply and quickly changed once the enclosure has been populated.

The enclosures incorporate digital equipment and fit ideally into the digital value chain of panel builders and switchgear manufacturers. Alongside the high-quality 3D data and the Rittal Configuration System, which accelerate the selection and planning processes, the presence of such features as QR codes on all the panels to be machined makes it easier to integrate them into the production workflow thereby paving the way for cutting-edge digital monitoring at every stage – from goods receipt all the way through to completion.

More flexibility

With the fibreglass enclosure AX, Rittal is for the first time transforming a fibreglass housing into an enclosures system – with greater scope for interior installation. Punched sections and rails can now be mounted on a 25-mm pitch pattern with the help of a universal bracket. The numerous mounting bosses both in the enclosure and on the inside of the door also permit custom expansion. The direct installation of accessories, such as support strips, punched sections and wiring plan pockets in the door means that plant constructors gain an additional mounting surface. As an option, the AX can be equipped with a mini comfort handle for all common lock inserts and profile semi-cylinder locks.

Nuts are pressed into the rear panel of the enclosure to ensure stable fastening and mounting on a wall or pole. Wall-mounting brackets can easily be attached to the outside of the enclosure without the UL approval losing its validity. As an option, the enclosure can also be screw-fastened to a wall or a machine.

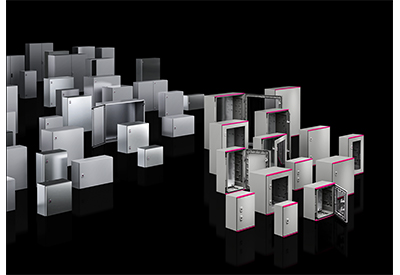

Rittal offers the fibreglass enclosure range in 14 different enclosure variants ranging from 250 x 350 to 800 x 1000 mm (W x H). Eight of them are available with a viewing window and six without.

![]()