Weidmuller USA: New RailAssembler and RailLaser Solutions Bring Automated Cabinet Building Closer to Customers

November 29, 2023

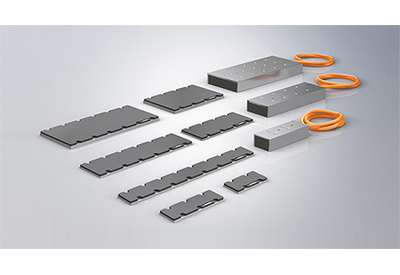

Weidmuller USA has recently announced the full operation of its Automated RailAssembler and RailLaser machines for a faster, more efficient way to assemble and mark terminal rails.

“We’re proud to offer our customers in North America the next level for automated terminal rail assembly and marking. It’s a game-changer for panel builders in every industry sector,” said Carlus Hicks, Director Cabinet Products Division with Weidmuller USA.

The Klippon Automated RailAssembler, in combination with the Weidmuller Configurator (WMC) software – a planning tool for selecting, configuring, and ordering terminal rails, enables the fully automatic assembly of terminal rails. The use of the automated system eliminates the need to pick, allocate and position individual terminals. The Klippon Automated RailLaser enables fully automatic marking of pre-assembled terminal rails. The use of terminal blocks with markers already attached eliminates the need to separate, assign and mount individual markers.

In fact, it’s the first automated terminal assembly and marking system in the U.S. for the fully automated building of a company’s control cabinet.

The RailAssembler and RailLaser are available on order for those companies who want to experience the future of automated cabinet building, with a time savings for operators of up to 90% from avoiding the need to pick, allocate, position and mark individual terminal blocks – making business flow faster, more precise and economically.

“The Automated RailAssembler and RailLaser round out our robust, scalable Workplace Solutions portfolio centered around matching solutions based on company size and business need,” added Hicks. “The RailAssembler and RailLaser are also a part of our assembly service offer, where our customers can quickly and easily order repeatable and accurate rail assemblies from our facility in Richmond.”

Features and advantages of the Automated RailAssembler and RailLaser include:

- Easy, optimized handling – The innovative design allows for easy handling through universal magazines with a large capacity, ensuring significant increases in productivity by reducing the filling processes and avoiding opening quantities.

- Contour robust gripper – The adaptive gripper allows complex component geometrics to be handled robustly, thereby maximizing the application range of the machine.

- Reliable quality – When paired with the Weidmuller Configurator, the continuous use of planning data from eCAD programs is possible, eliminating manual production steps and minimizing potential errors.

- Consistent transparency – The consistent software support during all work steps assists the worker and enables transparency of the order status, which guarantees a minimum error rate coupled with maximum efficiency.

- Maximum flexibility – The universal magazines make it possible to equip them with different components, ensuring maximum flexibility in operation. The RailAssembler has a total of 48 magazine places for components and 20 places for deflected DIN rails.

- Matching assortment – With Weidmuller’s standard markers, a suitable portfolio of the pre-loaded markers is available and can be used in combination with the Automated RailLaser to achieve full optimization potential.