Yokogawa Releases CENTUM VP R6.07

August 28, 2019

CENTUM VP R6.07 has been enhanced to enable communication with devices that support the PROFINET Industrial Ethernet standard. Also, new functions have been added to the Automation Design Suite (AD Suite) integrated engineering environment to improve engineering efficiency. These enhancements address the latest customer needs and boost productivity.

The CENTUM VP control system platform provides a robust, secure, and efficient operation, monitoring, and engineering environment for the entire plant lifecycle—from initial design, engineering, installation of systems and equipment, and startup to full operation, maintenance, renovation, modification, and end of service. Yokogawa has continued to enhance this system to ensure optimal performance, while ensuring full backward compatibility.

The versatile use of open field digital communications technology simplifies the task of selecting the best equipment and utilizing data for the maintenance of facilities. By introducing its field digital technology in plants and adding support for a variety of communication standards and protocols, Yokogawa has expanded the scope of facilities, devices, and equipment that can be operated and monitored in an integrated manner by CENTUM VP.

In addition, Yokogawa has continued to strengthen the functionality of its engineering environment with the goal of improving engineering efficiency in plant construction and expansion projects.

Enhancements

- Enhancement of field digital solution with PROFINET support

Yokogawa now offers a communications card for the PROFINET Industrial Ethernet standard, which is widely used in Europe. With this enhancement, the operation and monitoring of PROFINET devices as well as devices that support the FOUNDATION™ Fieldbus, HART®, PROFIBUS-DP, and ISA100 Wireless™ standards can be integrated into CENTUM VP. PROFINET, an Industrial Ethernet standard with excellent real-time performance, is mainly used at motor control centers and with programmable logic controllers (PLCs). - Increased engineering efficiency

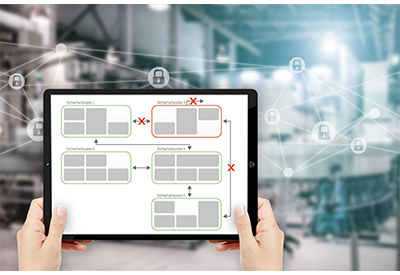

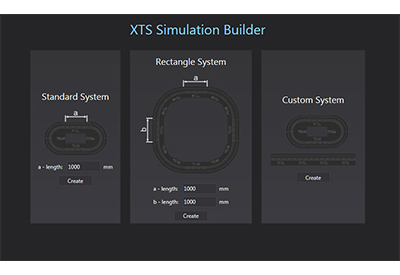

With CENTUM VP R6.07, Yokogawa has enhanced the functions of the AD Suite integrated engineering environment for the module-based engineering of control applications and alarm attributes. A new module grouping function is now available that enables the efficient customization and reuse of modules to construct similar applications. In addition, sequence applications have been added to the module library. This will enhance efficiency in the modification of sequential controls and other control programs.

Major Target Markets

Oil and gas, petrochemicals, chemicals, electric power, pulp and paper, pharmaceuticals, food, iron and steel, water supply and wastewater treatment, non-ferrous metals, metal, cement, etc.

Applications

Monitoring and control of plant operations

About the CENTUM series

Yokogawa released its CENTUM distributed control system (DCS) in 1975, a world first. CENTUM VP is the ninth generation in the CENTUM series. Known for their rugged performance, CENTUM systems set high standards for engineering and technology excellence while ensuring backwards compatibility with previous system versions and support of the latest technology applications. Knowledge-driven engineering lies at the heart of CENTUM, a Yokogawa flagship product that has been proudly serving the process industry over the past 40+ years.

The R6 series began with the 2014 release of CENTUM VP R6.01 and has been continuously improved to achieve smart engineering, advanced operations, system agility, and sustainability. The latest version has new functions that enhance smart engineering and system agility.

About OpreX

OpreX is the comprehensive brand for Yokogawa’s industrial automation (IA) and control business. The OpreX name stands for excellence in the technologies and solutions that Yokogawa cultivates through the co-creation of value with its customers, and encompasses the entire range of Yokogawa’s IA products, services, and solutions. This brand comprises the following five categories: OpreX Transformation, OpreX Control, OpreX Measurement, OpreX Execution, and OpreX Lifecycle. One of the product groups that make up the OpreX Control category is the OpreX Control and Safety System family, which includes the CENTUM VP DCS. With its various OpreX Control solutions, Yokogawa is able to quickly effect changes for its customers that lead to a transformation in such areas as management and operations, and provides highly reliable control technology that ensures high efficiency, high quality, and safe and stable plant operations.

With the OpreX brand, Yokogawa will deliver integrated solutions that address specific needs and support its customers in their efforts to transform and grow their businesses.