Balluff: IO-Link Wireless – Intelligent, Networked, Wireless

April 8, 2024

Combining industrial networks with the IO-Link communication standard is an essential building block of the smart factory of the future. Up to now, intelligent sensors and actuators as well as binary and/or analog devices have been integrated via cables. However, process- and factory-automation applications are increasingly using wireless technologies, since they have many advantages. IO-Link Wireless offers a promising new standard.

Balluff speaks IO-Link – both wired and wireless

Balluff’s extensive IO-Link portfolio includes sensors with different operating principles as well as an unrivaled range of network and connection technology. With IO-Link Wireless, Balluff is expanding it’s portfolio in a modern and future-proof way that maintains system integration and compatibility.

More flexible than any cable

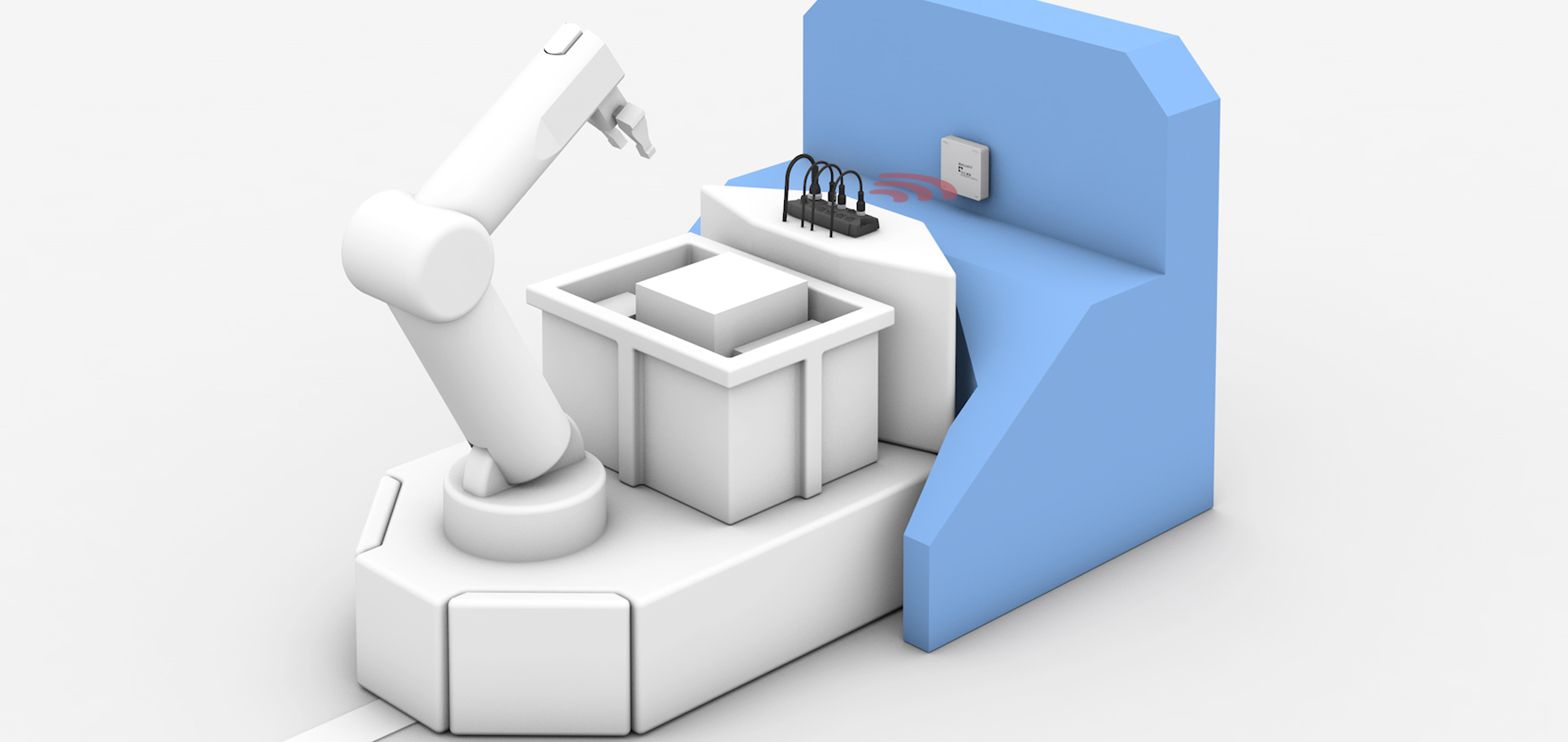

Balluff’s wireless system, consisting of a master block, hub and bridge, is built on a new wireless standard that meets the high demands of factory automation. The wireless master block does not receive its data by a cable, as is usually the case, but instead receives the sensor data wirelessly via a bridge or a hub. This brings decisive advantages over a wired system, including simpler planning and installation, more flexibility in design and mobility, and no wear and tear on connectors or cables. It also makes it easier to retrofit existing systems.

In short, wireless IO-Link allows even more flexible and sustainable integration of sensors/actuators, with the proven reliability and performance of wired IO-Link.

The factory of the future, now wireless

IO-Link Wireless is a new, promising solution for the factory of the future and a ready upgrade for all those who already use IO-Link and want to become even more mobile and efficient. The new standard is useful wherever wired data transmission was previously impossible or only possible with difficulty. A good example is on transport systems with high speeds, where compatible sensors can now be placed directly on the carriage for more precise monitoring. Or when changing tools on a gripper, the lack of cabling enables data transmission in confined spaces. The same applies to milling machines, which offer little space for sensors but require high process reliability. The new wireless system’s robustness earns it its place.

IO-Link Wireless Features

- Simple configuration via an integrated web server

- Frequency range 2.4 – 2.483 GHz can be used worldwide, license-free

- Fast and reliable (latency 5ms, error rate 10-9)