Wieland: Superior Safety, Less Effort – Decentralized Motor Starter for Easy Planning and Safe Operation of Conveyor Systems

March 29, 2022

Motors in conveyor systems need to be switched off safely, but the wiring and energy distribution involved is usually very complex, involving bulky cable trays, and complex distribution boxes. As a result, Wieland Electric has developed a new motor starter that reduces the complexity of installation and improves the safety of conveyor systems. The podis MS 5HP is a compact, robust and user-friendly drive component with an integrated STO (Safe Torque Off) function. The safety function disconnects the power supply from the emergency stop circuits completely. As a result, the STO circuits no longer need routing through a central distributor and assignment to a specific energy branch. The system is less susceptible to interference and the installation work is more easily planned and carried out.

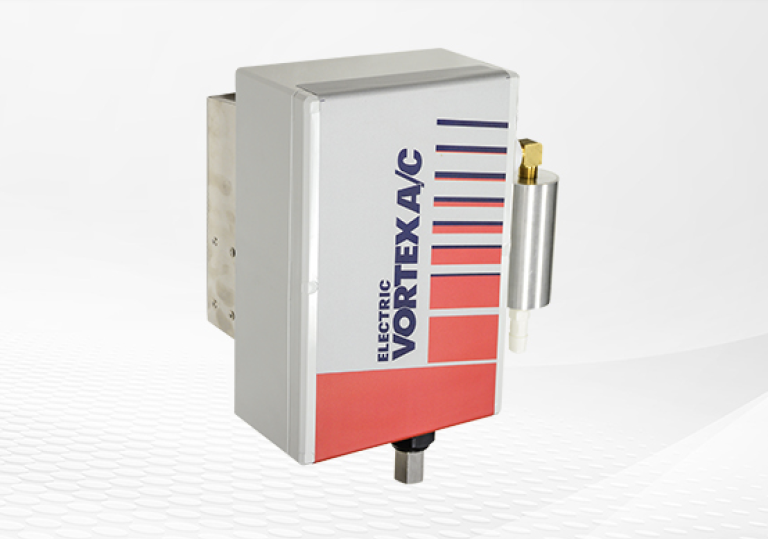

The motor starter podis MS 5HP from Wieland Electric makes the planning and installation of expansive conveyor systems less complex.

SAFE TORQUE OFF

The innovative combination of starter functions allows for the decentralized assignment of all of the energy of the STO circuits in the field. In addition, a superior level of safety (SIL 3, PL e) can be achieved with less effort. All the motor starters in an emergency stop circuit connect to the STO female sockets. The STO circuit monitors and operates through an auxiliary voltage generated in the field and also by a two-channel safety relay. Several STO circuits can operate from one power supply.

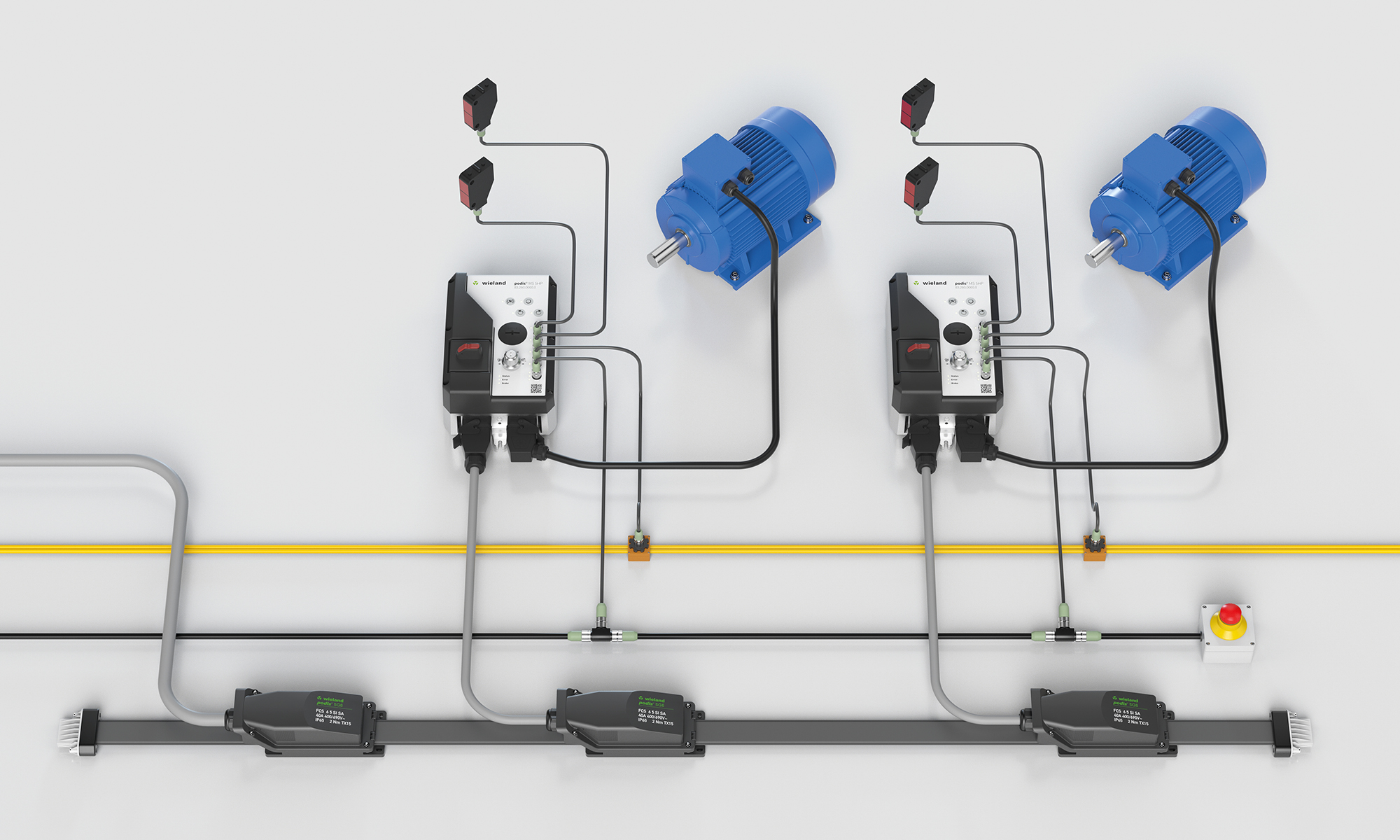

Using an energy bus system such as the podis 5G6 from Wieland Electric further enhances decentralized motor control. The energy distribution for several motors and starters can combine on one line with only a single feed. This saves space in the cable trays and the wiring in the distributor panel is much more straightforward.

Watch the podis motorstarter 5HP video.

MULTIPLE MOTOR SIZES, ONE STARTER

The podis MS 5HP covers motors with a power range from 0.3 Hp to 5 Hp (0.25 kW to 4.0 kW), up to 5 different motors. This helps reduce storage and administration costs. With only one order option for multiple motors, the procurement and materials management processes also require less effort. Installation and commissioning are simple as well. DIP switches, for example, can be programmed on the device or with a web tool. The web configurator guides the user step-by-step through the different options. To access the configurator, simply scan the QR code on the front of the device.

Use the podis energy bus system for a complete electrical installation of conveyor systems.

APPROVALS & PROTECTION RATING

With international approvals, CE, cULus from Q4 2021, the podis MS 5HP is suitable for worldwide use. In addition, the disconnect switch is in accordance with UL 508. The integrated service switch safely turns off drives for maintenance or repair work. Individual conveying lines can disconnect from the power supply without the system as a whole shutting down. A special integrated power supply generates the 24V DC auxiliary voltage required to supply the connected sensors. It does not use the neutral conductor and hence makes additional separate wiring unnecessary. This saves time and reduces material costs. Designed compliant with protection class IP65 and the NEMA12 standard relevant for the US market, the podis MS 5HP is also suitable for use in harsh industrial environments.

![]()