Rittal: Data Centre Containers With Blue e+ Cooling Technology

March 8, 2022

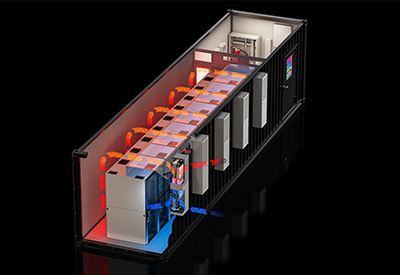

The digital transformation is challenging the data centre industry. Growing data volumes are forcing data centre operators to face the task of dissipating increasing amounts of heat from servers into ever tighter spaces or finding new space for expansion. And they have to do this as efficiently, sustainably and quickly as possible. Rittal is responding to the challenge with a new solution for IT containers that integrates an efficient Blue e+ outdoor cooling system in a space-saving way. Consuming a full third less power, this team manages the balancing act between cost-efficiency and sustainability. A cool dream team that supports IT managers as a smart all-in-one solution.

Each contributes their own benefits: the data centre container as a packaging artist, the Blue e+ cooling unit as a smart cooling expert. Working together, this new Rittal dream team can provide answers to several problems faced by IT and data centre managers: More and more data applications such as edge computing need an increasing amount of computing power, yet at the same time they need to operate with low energy costs, and in a sustainable and secure way without any hotspots. This calls for all-rounder solutions that can also manage with a small footprint. Rittal’s IT Container is geared towards these future needs: With the aid of a new outdoor cooling solution on the outside of the container, based on the industry-proven Blue e+ technology, more space is created within the modular data centre container for the constantly growing information technology. This also provides the added potential for flexibly expanding the applications. At the same time, energy consumption is reduced by a third. This makes it easier for data centre container operators to save on operating and energy costs. Furthermore, it is no longer necessary to install the previously needed raised floor and the corresponding cooling technology inside the container – nor the otherwise usual refrigerant piping between the inner and outer circuits. The cooling unit can thus be directly attached to the container’s wall cut-out. This not only saves space, but also assembly work, while saving assembly time and money.

Robust, efficient and controllable

“The outdoor devices of the Blue e+ series are not only robust and easy to maintain, but also highly energy-efficient due to their innovative heat pipe technology. They leave a smaller carbon footprint,” explains Philipp Müller, Director Data Center Solutions at Rittal. This lowers the overall operating costs in the long run. The IoT interface fitted to the cooling units also helps. All the performance parameters of the cooling system can be seen on the web interface. “This lets the IT operator manage consumption as efficiently as possible.”

The Blue e+ principle

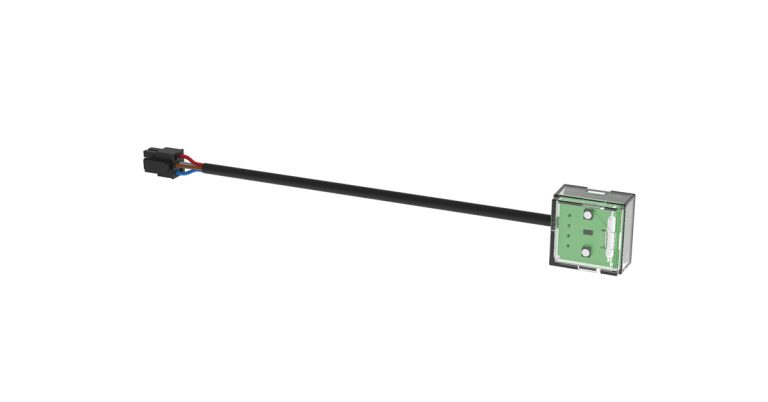

The successful efficiency is achieved by the Blue e+ series’ hybrid technology. Besides an active cooling circuit for appropriate cooling, each Blue e+ cooling unit also possesses a passive cooling circuit: Due to the integrated heat pipe, heat is dissipated to the surroundings as soon as the ambient temperature falls below the internal temperature in the container’s hot aisle. This effect has an enormous impact on efficiency, especially where temperature differences are great.

![]()

https://www.rittal.com/com-en/Company/Presse/Pressemeldungen/Blue-e–RZ-Container