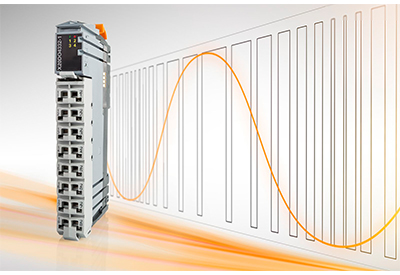

Application-Based Controller Redundancy (ACR) From WAGO

August 23, 2021

Crew-free ships – not the romantic notion of a sailor? Initiatives for autonomous ships are driving this development. However, there’s a long way to go in getting engine rooms, which can currently operate for up to 24 hours straight without direct intervention, to a completely autonomous ship that should be able to run for up to six weeks at sea without human intervention. WAGO’s redundancy concept for controllers is shortening this path and offers a solution for compensating for faults occurring in the automation systems while ensuring the continued operation of technical systems.

The greatest challenge on the way to increasing ship automation is still establishing onboard systems that are so reliable that outside intervention is unnecessary. This can be achieved by using a larger proportion of standardized components on board, while maintaining high availability of security relevant systems through redundancy. In order to guarantee the automation systems’ reliability, the voltage supply and the communication medium (e.g., ETHERNET), in addition to the PLC, must satisfy the technical system’s uptime requirements. WAGO provides a simple and economic solution for its maritime customers that uses an application-based redundancy concept for controllers.

WAGO’s e!COCKPIT engineering software tool is used as the programming environment for the controllers. The multi-node programming environment can easily transmit the PLC program to both PLCs. For the application-based controller redundancy to be used, a software library with the necessary synchronization functions must be linked to the master PLC. The library offers the possibility of redundantly linking subnodes using a dual LAN. The subnodes, also known as smart couplers, do not have to be programmed; they can be simply booted from an SD card and then configured using an integrated webserver. Both analog and digital input/output modules are detected automatically by the smart coupler; process mapping is likewise automatically made available to the higher-level master PLCs. The master PLCs can communicate with higher-level SCADA systems via the Modbus-TCP protocol. The redundant connection is performed over two separate networks.

The solution’s design corresponds to an SPOF-tolerant system (single point of failure), which means that any occurring fault – like a voltage supply failure, a poor LAN connection, switches, or controller – can always be compensated for. Doubling the ETHERNET topology and the redundant message transmissions enable instantaneous switching during a network fault. Typical switching times after a PLC failure are within DNV GL requirements when used in typical alarm and monitoring systems.

![]()

https://www.wago.com/us/alarm-monitoring/application-based-controller-redundancy