Schneider Electric Enhances Safety & Alarm Software

May 17, 2021

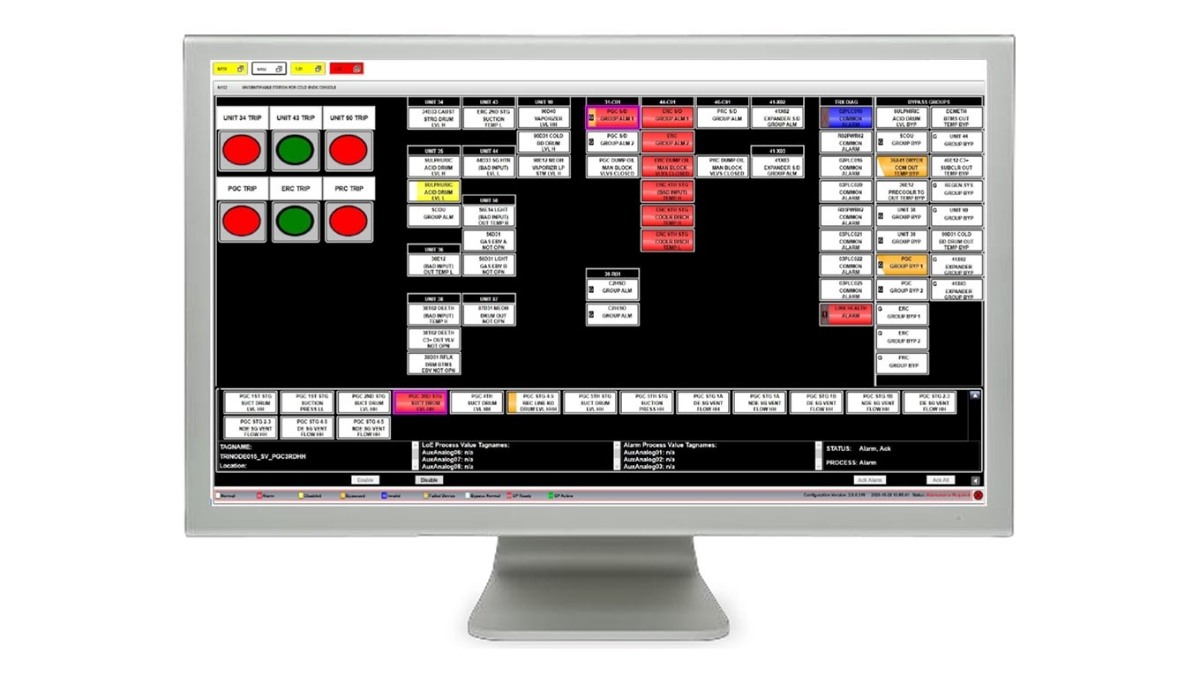

Schneider Electric has released an improved version of its EcoStruxure™ TriconexTM Safety View, the industry’s first dual safety- and cybersecurity-certified bypass and alarm management software application. The EcoStruxure Triconex Safety View empowers control room operators to make the best decisions is critical to safe operations and better manage safety risks, including risks that threaten the performance of their operations. EcoStruxure Triconex Safety View allows to identify, mitigate and avoid future risks. Therefore, it contributes to better overall business performance, including better productivity, better profitability, and better sustainability.

Because EcoStruxure Triconex Safety View is proven to improve uptime while helping to reduce operating, maintenance and engineering costs, it provides measurable improvements to the profitability of the operation, as well as quicker ROI and better total cost of ownership.

Industrial process safety systems are designed to help prevent unsafe operating conditions, as well as to bring the plant to a safe state, sometimes via a shutdown, when operating conditions become unsafe. Because of their critical role in helping to protect people, assets, production and the environment, safety systems are always “on.” During everyday operations, there are instances where bypasses need to be implemented or critical alarms suppressed, which directly impacts the overall levels of operational risk and the safety of the plant. Every time this happens, the performance of protection functions is impacted, which increases cumulative risk and the likelihood of an incident, which means increased risk to the company’s people, production, and profits.

During these high-risk times, operations need to know what has been bypassed and then manage the elevated risks, paying attention to critical process conditions and critical alarms affecting production and profitability. EcoStruxure Triconex Safety View allows operators to see both the bypass status that impacts the level of risk reduction in place, as well as the critical alarms required to operate the plant safely when risks are high. And because the software has been certified by TÜV Rheinland as Security Level 1 (SL1) compliant per IEC 62443-4-2 and Systematic Capability 3 (SC3) compliant per IEC 61508 for use in safety-related applications up to Safety Integrity Level 3 (SIL3), it meets stringent requirements for safety, cybersecurity, risk reduction and continuous operation in the oil and gas, refining, petrochemicals, power and other high-hazard, risk-intensive industries.

![]()

- Ideal replacement or alternative to traditional hard-wired annunciator panels

- Adaptable design allows configuration to your specific requirements

- Standardization lowers costs

- Enhance operator performance

- Provides more contextual and intuitive information to the operator

- Reduce the likelihood of an adverse safety event

- Minimize the likelihood of unscheduled asset downtime

- Minimize operator errors

![]()