nVent Launches New Air-Water Heat Exchanger

April 7, 2021

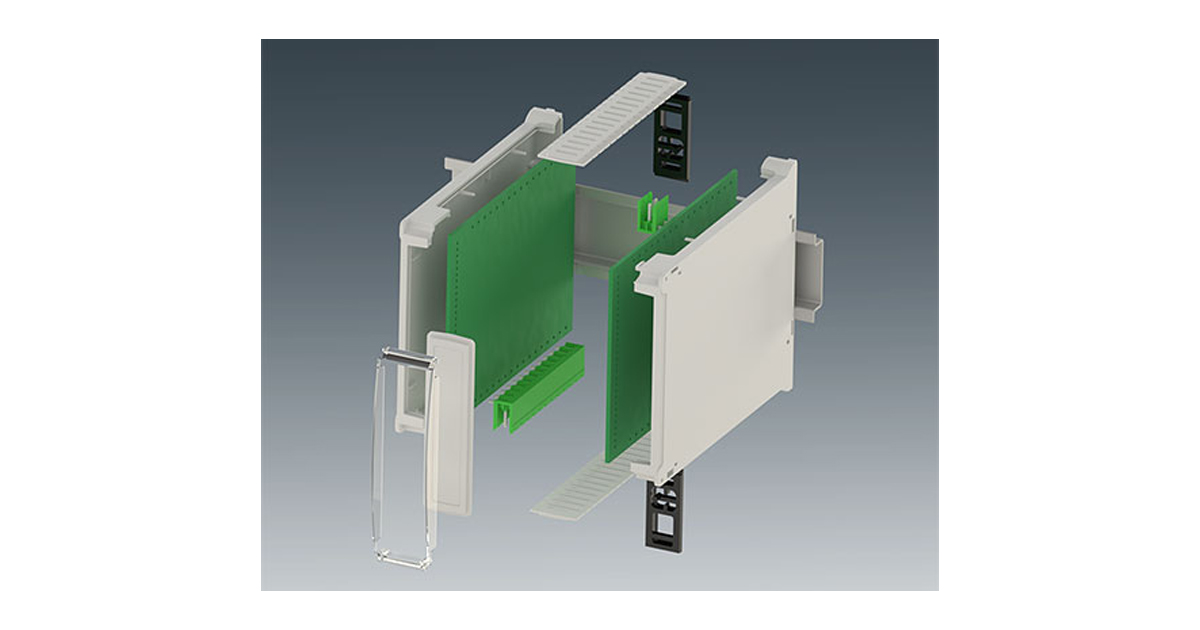

nVent Electric plc recently introduced the nVent SCHROFF Varistar LHX+, a standardized modular cooling system with a cooling performance of up to 10 kW. The system is built into the nVent SCHROFF cabinet and uses a specialized air-water heat exchanger to cool the electronics to a precise temperature to optimize performance.

“We have developed a market-ready cooling unit that can be used in any application that requires the highest degree of measurement precision, such as large-scale research facilities that support particle physics, medical and pharmaceutical research,” says Pradipto Bhowmick, nVent global product manager of electronics cabinets. “It arrives at a perfect time: as the electronic density in applications increases, the demand for precise system cooling is also rising.”

The complex test and measurement industry processes require precise temperatures to function within operational parameters. The LHX+ offers temperature control precision of +/- 0.1 °C / K peak-to-peak, ensuring reliable performance for these operations.

Cooling concept: standard components with plug-and-play operation

Installations for test and measurement applications often require limited space, meaning cooling solutions must be compact. The LHX+ requires a floor space of only 600 x 800 mm (W x D), which is the size of a 40” monitor. Its cooling capability is scalable too. The electronics cabinet attains an airflow volume of 1000 to 1800 m3/h. If necessary, its cooling performance can be increased without having to adjust the infrastructure inside the cabinet. To accommodate greater cooling capacity, a dual fan cooling unit, with a cooling performance of 10 kW can be swapped with the single fan cooling unit, that supports 5 kW cooling performance.

Control unit: 19″ high tech

The high-precision temperature control of the LHX+ is possible because of a control unit and also a modular design, with the option of remote access and control. The EtherNet, SNMP, Modbus, TCP, web interface protocols are available for remote applications. The temperature can be controlled via a terminal with a display and keypad mounted on the door or remotely via Ethernet access and a web interface. The electronics cabinet can stay closed while accessing the controller capabilities. Four air temperature sensors that monitor the temperature in the cabinet are located inside the housing. A differential pressure sensor monitors and controls the installed cooling unit’s fan speed. Optionally, the throughput and flow temperature of the coolant can also be recorded. This independent plug and play control unit is also a separate 19″ module that can be easily mounted, closed from the outside and requires little installation work.

![]()