DOLD: Safe Sensorless Standstill Monitoring

March 16, 2021

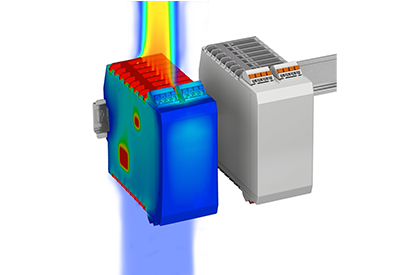

The safe sensorless standstill monitor UG 6946 from the SAFEMASTER S series detects the standstill of 3-phase and 1-phase motors independent of the direction of rotation. This means sensors such as encoders or proximity switches are not required. Access to the danger zone of a system is only possible by the enabling signal of the standstill monitor after the drive has been switched off and run down. In order to detect a standstill, the remanence voltage induced by the motor windings is evaluated and provides safe standstill monitoring up to Cat. 4 / PL e or SIL 3, even if the motor has already been switched off. Using a conventional release via a time control, dangerous movement could not necessarily be excluded. For the implementation of different operating modes, the standstill monitor UG 6946 also offers the possibility of bridging the standstill monitoring (muting).

The simple integration into the machine and drive concept reduces the commissioning effort and costs and is particularly suitable for use in machine tools and woodworking machines, centrifuges and rolling drives. With a width of only 22.5 mm, the UG 6946 can be accommodated in the control panel even under tight space conditions allowing easy retrofitting. The device also offers two redundant safety contact paths and a forcibly guided signal contact.

Advantages and customer benefits

- – Space saving in the switch cabinet due to only 22.5 mm width

- – Adjustable response voltage 20 – 400 mV or 0.2 – 4 V

- – Possibility of bridging the standstill monitoring (muting function)

- – Standstill detection without additional sensors

- – For safety applications up to Cat. 4 / PL e or SIL 3

- – Rotary switches protected by sealable transparent cover

- – Can be combined with safety interlock SAFEMASTER STS

![]()

https://www.dold.com/en/company/news/safe-sensorless-standstill-monitoring