Yokogawa to Begin Offering OpreX Batch Solution with Enhanced Portfolio for Batch Plants

February 22, 2021

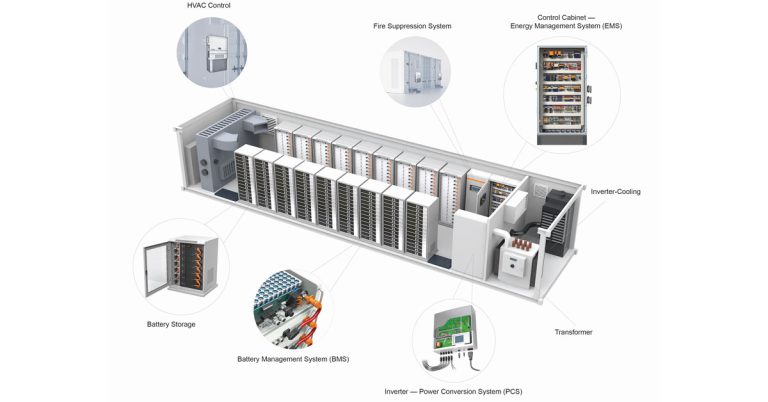

Yokogawa Electric Corporation recently announced that it will begin providing OpreX Batch Solution on March 17. This solution for batch manufacturing applications eliminates the overlap between process control system (PCS) and manufacturing execution system (MES) related work and helps to enhance efficiency through all phases of the plant lifecycle, from design and engineering to actual operation, modification, and expansion. For use as a central element of OpreX Batch Solution, Yokogawa has also developed Integrated Recipe Manager (IRM), and will be releasing this product on the same date.

In many areas of the specialty chemical, pharmaceutical, and food & beverage industries, product lifecycles are becoming shorter while at the same time product variety is increasing. In addition to needing to rapidly develop and deliver new products, batch manufacturers face the challenge of maintaining stable operations while dealing with shortages in the availability of experienced personnel.

To address these issues, Yokogawa is offering OpreX Batch Solution, an integrated portfolio for batch manufacturing processes that is aligned with both the ISA-88 Batch Control standard and the ISA-95 Enterprise-Control System Integration standard.

Benefits

-

Increased cost effectiveness in batch operations

With product lifecycles becoming shorter, customers must strive for cost effectiveness in all phases of the plant lifecycle, including plant/process design, implementation, and operation.

OpreX Batch Solution helps to ensure both cost effectiveness and high production quality by employing a simplified and compressed PCS and MES design process. Reusable standard modules are available for PCS design and engineering that make it easier to develop applications and help to maintain engineering quality.

As a key part of OpreX Batch Solution, IRM provides an engineering environment with graphical tools and reusable template modules that can be used to effectively manage batch control systems and master recipes* in batch management systems. By enabling the direct design of systems in this engineering environment, IRM also greatly improves efficiency by eliminating the need for the creation of documents such as user requirement specifications and functional design specifications.

MES design and implementation is also simplified and compressed through the cultivation and capturing of know-how using MES templates. These help to speed up MES design and implementation by covering the typical MES functions of recipe management, order management, inventory management, execution management, field operation support, reporting, and lot tracings?while providing integration with related systems.

-

Reduced time to market

As product lifecycles grow ever shorter, it is increasingly important for batch plants to quickly deliver new products to the market. With a graphical approach based on proven reusable modules, IRM simplifies recipe engineering and enables flexible changes to both recipes and formulas. Thanks to Yokogawa’s proven CENTUM™-VP module-based engineering environment, the engineering workload for plant expansions is dramatically reduced.

-

Improved production quality

As plants are called upon to deliver an ever-greater variety of products, production processes are growing ever more complex. At the same time, plants must make do with fewer experienced personnel while trying to achieve the stable production of high quality products. OpreX Batch Solution helps to ensure product quality by enabling the comparison of production batches with previously baselined “golden batches,” enabling the notification of field operators whenever an error is made in a manual operation. Problems in manufacturing operations can be identified and solved by using a manufacturer’s operational data and Yokogawa’s analytics technology.

![]()

https://www.yokogawa.com/news/press-releases/2021/2021-02-19/