Yokogawa Releases CENTUM VP R6.08 Integrated Production Control System

January 26, 2021

On January 20, 2021, Yokogawa Electric Corporation announced that it would be releasing CENTUM VP R6.08, an enhanced version of the CENTUM VP integrated production control system for industrial plants, and released it two days later on January 22. CENTUM VP is a core product in the OpreX Control and Safety System solutions family.

This release delivers enhancements that drastically reduce the amount of work needed to upgrade a control system’s CPU module, including a newly developed utility kit and standards certification for individual CPU modules. It also enhances a function that is able to upgrade a CENTUM VP system without interrupting the process control. Providing a smooth upgrade process will help customers achieve long-term stability in their plant operations and enable the efficient utilization of assets.

Development Background

Availability and efficiency are always primary concerns in plant operations. To stay competitive, companies with plants that have been in operation for 10 to 20 years or even longer frequently need to install new equipment that makes use of the latest technologies.

Ever since it introduced the first version of CENTUM VP (R6.01) in 2014, Yokogawa has continued to make enhancements to this platform that will ensure its customers are able to enjoy long-term stability in their system operations. This latest version of CENTUM VP meets our customers’ needs for faster equipment upgrades and high availability.

Development of this new CENTUM VP version is also in keeping with Yokogawa’s three sustainability goals for the year 2050, one of which calls for the achievement of a circular (recycling-based) economy. Toward this end, we are working to help our customers use their existing facilities for longer.

Enhancements

- CPU module upgrade without need to replace cabinet

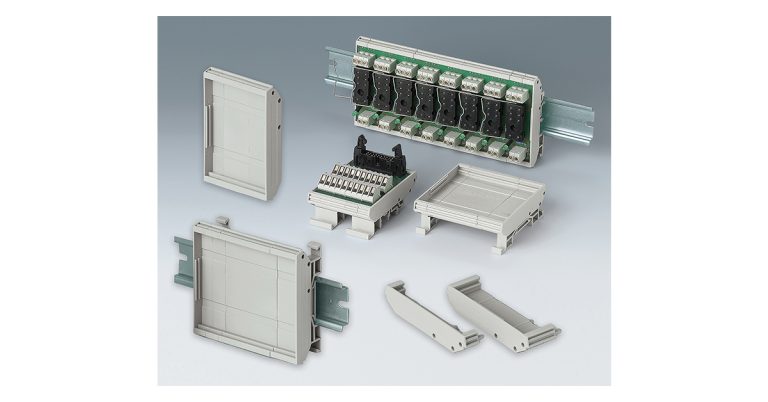

When upgrading a CENTUM VP controller’s CPU module, it has also often been necessary to replace the cabinet that houses these components. Replacing and rewiring these cabinets, which are around two meters tall and weigh more than 200 kilograms, is a very time-consuming process.Yokogawa has developed a utility kit that eliminates the need to replace the cabinet when upgrading the CPU module. This kit includes environmental sensors and cooling fans. By eliminating the need in many cases for the complete replacement of the cabinet, this reduces workload, prevents waste, and lowers the barriers to the introduction of new technology. In so doing, Yokogawa is helping its customers achieve long-term stability in their plant operations.

- Enhanced online upgrade function for batch processing operations

From time to time, it is necessary to upgrade the system software of a control system’s CPU modules with new functionality to improve both operability and the engineering environment. In the past, such upgrades required the production process to be shut down for several days.CENTUM VP R6.05, which was released in 2017, included an online upgrade function that eliminated the need to halt a plant to perform such upgrades, and gradual improvements have been made to enable a wider range of applications. With version R6.08, this online upgrade function has been enhanced with the addition of support for SEBOL, the principal programming language for batch processing sequence control.

- CPU module replacement without invalidating certification to local standards

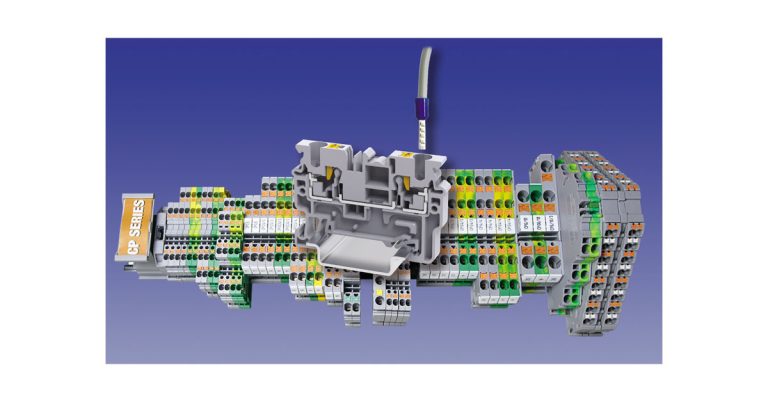

Until now, certification for compliance with local explosion-proof and safety standards has needed to be done for the field control unit as a whole. This means that certification for the entire unit, which in addition to the CPU module includes a power module and terminal block, would be invalidated when just the CPU module was upgraded.With R6.08, certification to these standards has been obtained for the CPU module and for each of the other components, so replacement of just the CPU module will no longer invalidate certification for the entire field control unit. Enabling the replacement of individual components reduces costs over the long term, and also lessens the need for the addition or removal of wiring. This increases operational efficiency and also reduces the attendant risks of any wiring errors. And as with the above-mentioned enhancement that eliminates the need for discarding entire cabinets, this feature reduces waste by eliminating the need to replace the entire field control unit just to upgrade the CPU module.

Major Target Markets

Oil refining, petrochemicals, chemicals, electric power, pulp and paper, gas, pharmaceuticals, food, iron and steel, water supply and wastewater treatment, non-ferrous metals, metal, cement, etc.

Applications

Plant operational monitoring and automatic control