GraceSense: Find Faults Before They Find You

January 21, 2021

Electrical system breakdowns are a leading cause of equipment and business interruption losses. It’s a growing problem and the losses can be substantial. A common factor in determining the reliability and uptime of an electrical system is the condition and the availability of the power distribution equipment such as medium voltage and low voltage switchgear, transfer switches and MCCs used in the downstream.

Since loose connections contribute to over 30% of all electrical failures and a major cause for power outages, we’ve devised a solution to monitor those failure points and prevent untimely downtime. By continuously and remotely monitoring your critical uptime assets, you can rest assured knowing you’ll be alerted to problematic behavior before it becomes catastrophic by resulting in unplanned downtime.

About the Hot Spot Monitor

The GraceSense Hot Spot Monitor (HSM) is a non-conductive temperature monitoring device that detects potential hot spots and alerts personnel of any temperature anomalies occurring in electrical equipment. The ability to identify faults before they occur saves money when unplanned outages, service interruptions, and equipment failures are avoided entirely in lieu of predictive maintenance monitoring.

Additionally, by integrating HSM with a GraceSense Panel-Mount Node, data from the HSM can be remotely monitored along with other equipment parameters within the Maintenance Hub. The Hub displays system information and issues SMS and email alerts with actionable step-by-step remediation instructions.

Applications

Current flowing through electrical connections (lugs, screw terminals, circuit breaker stabs, busbar joints, etc.) is the main cause for electrical hot spots. The integrity of internal bolted connections, (i.e. PFPs), can be compromised when electrical equipment is subjected to wide load fluctuations or high harmonics.

The following are potential applications:

- – Low voltage/medium voltage switchgear

- – Low voltage/medium voltage MCCs and Drives

- – Motors, generators and dry-type transformers

- – Load break & Transfer switches

- – Bus ducts & busbars connections

- – DC switchgear/MCC/Drives

- – Large UPS batteries and inverters

- – High current junction boxes

Potential Failure Points

Equipment operating temperature significantly impacts the overall useful life. Most electrical systems are designed for 40°C – 45°C ambient temperature. Every 10°C rise in temperature shortens the average reliability of electrical components by 50% percent.

Hot Spots Occur Due To:

- – Loose connections

- – Vibration

- – Aged/unmaintained equipment

- – Unbalanced loads

- – Overload conditions

- – Harmonics caused by non-linear loads

- – Ambient conditions and thermal cycles

- – Mechanical stresses due to high magnetic forces during faults or high starting currents.

Installation

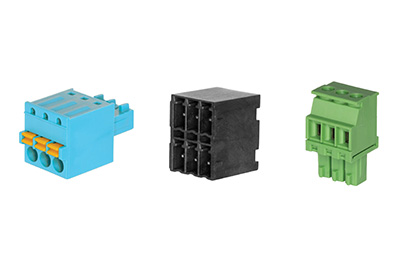

Mount the HSM module on a DIN rail inside of a low voltage or control compartment. Securely attach the fiber temperature probe to the ring-style connector and mount the probe assembly to existing bolted connections inside of the electrical equipment where heat sources (busbars, lug connections, etc.) or Potential Failure Points (PFPs) often originate. Once the bolted connection is made, route the other end of the fiber through the equipment and attach it to the HSM module inside the low voltage compartment.

![]()

Features & Benefits

- – Available in two formats; an 18-point temperature monitoring module and a 9-point module which includes an LCD Display.

- – Utilizes non-conductive technology that can be safely applied to any electrical system.

- – Continuous temperature monitoring and alarming device that identifies problematic hot spots in electrical equipment before an inevitable failure and costly shutdown occur.

- – Plant-wide integration is made simple when the device is connected via MODBUS TCP/IP or Ethernet IP.

- – Integration with our Maintenance Hub provides a User Interface for real-time analytics and configurations.

- – The purchase of any HSM includes a 5-Year Product Warranty.

![]()