SCHURTER: 3-Phase High Performance EMC Filter Fits in Tight Industrial Spaces

December 22, 2020

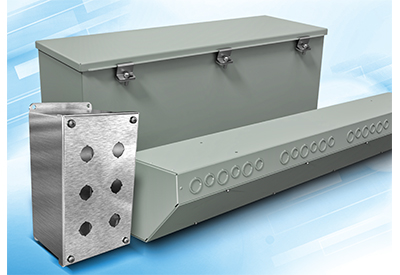

SCHURTER recently introduced the FMBC EP double-stage filter family for 3 phase systems. The filter packs in high performance in a compact package, ideally suited for today’s space constrained machine and industrial plant construction. Versions with high nominal voltages are particularly suited for a wide field of applications.

Space is scarce in control cabinets for 3-phase industrial applications. SCHURTER has addressed this problem with downsizing its EMC filter range, which is much more compact than previous generations. The new, almost cuboidal design, makes optimum use of the space in the housing. The double-stage filter built with the highest quality components (generously sized film capacitors, chokes with highly permeable cores), provides exceptional broadband filter attenuation.

The double-stage filter family is therefore also appropriate for applications with particularly high EMC emissions, as is frequently encountered in machine operations. Typical applications include automatic production, motor drives and industrial plant machinery. These powerful filters are also the first choice for modern frequency inverters for motor control.

The FMBC EP series features screw terminals for absolutely safe wiring. A metal flange provides an excellent earth connection when screwed to the chassis. Standard types can be used over a wide temperature range from -40 °C to 100 °C. The filters are designed for currents from 16 A to 230 A at an ambient temperature of 50 °C. They have both ENEC and cURus approval and are recommended for applications up to 520 VAC or even 760 VAC. The standard versions are designed for industrial applications with leakage currents <4 mA. Special variations, rated with <1 mA leakage current, are available for applications where minimizing leakage current is critical.

![]()

- Compact design with small footprint

- Double-stage filter for high attenuation

- High voltage versions

- Wide temperature range

![]()