FLIR Launches Always-On Vibration and Temperature Condition Monitoring Kit for Industrial Inspection

December 22, 2020

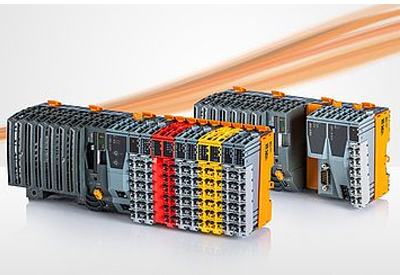

Often before industrial machinery start showing issues that require immediate maintenance, pending problems can be detected through minute vibration changes. Therefore, the first component of effective condition monitoring is a combined remote vibration and temperature sensing monitoring solution.

Manufacturing facilities from paper mills, to food and beverage processors to the oil and gas industry benefit from 24/7 remote condition monitoring of critical infrastructure and machinery. By combining the power of FLIR’s vibration and temperature detection, industries now have a complete solution kit that maximizes production output, improves worker safety, and reduces operational costs.

Vibration detection not only provides early warning to help eliminate maintenance surprises before they happen, it also empowers staff to prioritize and streamline its maintenance schedule to maximize efficiency while reducing down-time. However, traditional wired continuous vibration monitoring systems can be expensive, not always up to date, and cumbersome to install.

The FLIR SV87-KIT, on the other hand, is low cost, easy-to-configure, and can install on any surface with wireless connectivity to a Wi-Fi network. This also provides maintenance staff with the ability to track changes in vibration and heat in real time and over time, providing operational insights to predict potentially serious problems before failure.

![]()