Allied Electronics & Automation: HARTING’s T1 Industrial for Single Pair Ethernet

December 1, 2020

Single Pair Ethernet is the future of industrial Ethernet connectivity. HARTING understood this in 2015 when design began of a connectivity solution that would serve as the industrial and heavy industrial standard for Single Pair Ethernet. HARTING took the best parts of Ethernet technology already available, analyzed and removed the pain points of the current industrial Ethernet connectivity, and innovated the T1 Industrial.

How Single Pair Ethernet (SPE) Enables the IIoT

Based on a uniform and standardized infrastructure of cables and interfaces, device and chip developers start their work. Only when the networking of the devices is securely guaranteed do they have the necessary security to invest in a completely new market. With the T1 Industrial style interface, such an interface is available. It complies with all relevant standards and also harmonizes with the SPE cable standards.

T1 Industrial Technical Overview

The T1 industrial connectivity solution was designed to be the standard interface for industrial Single Pair Ethernet applications. The product ranges from IP20 to IP67, and currently there are metric variants (M8 and M12), with further variants on the product roadmap. To fit all applications and truly be the standard for industrial applications, the mating interface was designed to be the same and interoperable across all IP-ratings.

The Mating Interface

Unplanned downtime and outages in manufacturing facilities are a critical concern. This is particularly frustrating when it is due to a small component of the infrastructure that cannot withstand the tough demands. This was sometimes the case with previous versions of industrial Ethernet connectivity, which no clear standard in place and the most popular version of connector not originally being designed for industrial purposes. HARTING main this a main priority when designing the T1 Industrial connectivity solution. The shield plates are manufactured out of stainless steel, and HARTING implemented a robust core and a reliable cable gland provide enough stability to widthstand all applications across various IP-ratings.

The Standard Mating Face

For the past few decades, many variants of industrial Ethernet have been designed in reaction to the needs of the market. Instead of being reactionary with Single Pair Ethernet, HARTING took a proactive approach to designing one industrial connectivity solution that would fit all application needs. Some conditions call for enclosures with quick-release locks or screw terminals with metric/inch dimensions. Depending on the field of application, IP-ratings could be IP20 or IP67. In order to be able to use these proven sizes and dimensions further, the T1 Industrial interface has been developed using a container principle. It fits into well-known M8 and M12 circular housings, or other housings and can thus adopt the protective properties of this proven standard. At the same time, an IP20 T1 Industrial can be plugged into an open IP 65/67 interface for service purposes, making it easy to maintain.

A Strong Connection

You know the moment when the plastic clip of the LAN connector has broken off? Just because you got stuck on the cable carelessly. Such moments of material weakness have no place in industrial applications. For this reason, the T1 interface is equipped with a robust metal lock made of stainless steel for a strong connection even under harsh conditions.

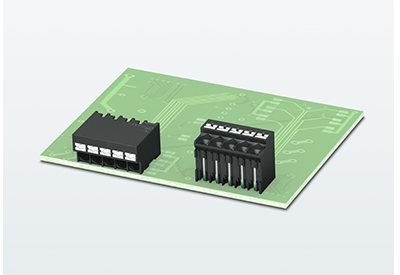

Miniature Design, Robust Placement

SPE is not only a game changer for the interface and cabling, it also saves a lot of space. Miniaturization is a major point in design criteria for next generation products, and the market is taking shock and vibration testing much more seriously as on-machine application becomes more popular. For these reasons, component mounting and stability must not be neglected. The T1 Industrial PCB mounted socket has four robust THR shield contacts, which are reliably soldered into the PCB and provide the best stability. The contacts are also designed as pin-in-hole variants. Should the socket have to absorb unexpected high forces, they cannot simply detach from the surface.

Shielding and Protection

In order to meet the high frequency requirements of SPE, SPE infrastructure must be particularly well shielded. The standard interface now developed for industry has therefore been fundamentally designed to meet these requirements. A completely symmetrical mating face in connection with a horizontal device socket ensures consistent and reliable running times in both copper wires in order to avoid signal overlapping. A complete 360 degree closed stainless steel jacket, which encloses the entire connector, ensures excellent electromagnetic compatibility (EMC) and protects what is important: the data of your production.

![]()

https://www.alliedelec.com/product/harting/33280101001005/72057548/