Acromag Loop-Powered Digital Panel Meter Streamlines Installation

November 16, 2020

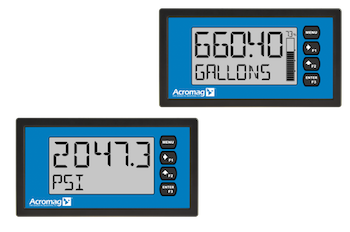

The newest addition to Acromag’s Vertu™ brand of innovative instrumentation is the VPM2000 Series of loop-powered display meters with process current output and alarm capabilities. These instruments supplement the digital indicator functions of a panel meter with optional 4-20mA isolator output and/or alarm trip solid-state relays. A dual-line LCD display has large 0.7 inch digits, an optional bargraph, and a backlight for clear visibility in bright sunlight or dim lighting. The backlight glows red and flashes under alarm conditions. No separate power supply is required for easy installation almost anywhere. They are even UL/cUL approved for use in hazardous locations requiring intrinsically safe, non-incendive devices.

The VPM2000 displays are simple to set up and install. USB connection to a PC makes setup fast and easy with the free configuration software which can save the file for copying to other units. Front-panel pushbuttons can also set operating parameters and serve as function keys to change the display or acknowledge alarms. A shallow-depth 1/8 DIN enclosure with a NEMA 4X IP65 front panel facilitates mounting. Internal PCBs are conformal coated for protection from the elements while a -40 to 75°C operating range enables use in extreme environments.

“These versatile instruments combine the functionality of a 4-20mA signal isolator, a dual-relay limit alarm, and a digital display in a single unit that is powered off a process current loop” explains Robert Greenfield, Acromag’s Business Development Manager.

Other advanced capabilities add further value. Two open collector outputs and a digital input are standard. The discrete outputs are useful for alarm indication or pulse output. The discrete input can trigger or reset alarms. Square root, exponential, and linearizer calculations perform scaling for flow and volume computation. The two-line display can show the measured process value in different scales such as tank height on the top line and volume on the bottom. Pushbuttons toggle display of min/max values or other units. Dual relays enable a variety of alarm trip configurations for high/low, high/high, and low/low limit triggers. Relays can also be used for process on/off control and pump alternation applications with display of runtime and cycle counts.

Acromag, a mid-sized international corporation, has been developing and manufacturing measurement and control products for more than 60 years. They offer a complete line of industrial I/O products including process instruments, signal conditioning equipment, data acquisition boards, distributed I/O systems, and communication devices.

![]()

- Loop-powered Process Meter

- 4-20mA input/output

- Solid-state relays

- Non-incendive, intrinsically safe

![]()