Safety Scanner or Safety Mat? How to Choose the Right Safeguarding Device

August 24, 2020

You’ve done your risk assessment, and now it’s time to implement a risk reduction strategy using engineering control measures. Since physical barriers can be costly and impractical, many manufacturers opt for what are known as presence sensing devices, a category that includes technologies like safety light curtains, safety laser scanners and safety mats.

Because they don’t physically prevent an operator from reaching the hazard zone, presence sensing devices only work for machines that can be stopped anywhere in their cycle. Each device must be positioned far enough away from the machine that it’s extremely unlikely for anyone to be able to reach the danger area after triggering the safety response.

In this blog post, we’ll compare two presence sensing devices – safety scanners and safety mats – to help you choose the best safeguarding solution for your machine.

Safety mats: A cost-effective solution that functions well in harsh environments

Safety floor mats are basically pressure-sensitive electric switches that can detect either foot or vehicular traffic. They’re ideal for risk reduction strategies that require startup prevention or machine shutdown. Because they’re low maintenance, they can be a great way to enable safe access to hazardous areas for repetitive operations like loading and unloading.

Safety mats also provide a clear visual reminder to personnel to help them identify the safeguarded area. In general, they’re the ideal option for challenging application environments with the following characteristics:

- Abundant dirt, smoke or dust

- Extreme heat or bright light

- Frequent shock or vibration

- Spray from water or chemicals

- Difficulties with implementing hard guarding

One major challenge with safety mats is that they can’t be easily relocated or modified to adapt to a new machine or application. They can also be expensive for larger or irregular areas, and they take up a fair amount of valuable floor space.

Safety scanners: A flexible solution for protecting large and/or irregularly shaped areas

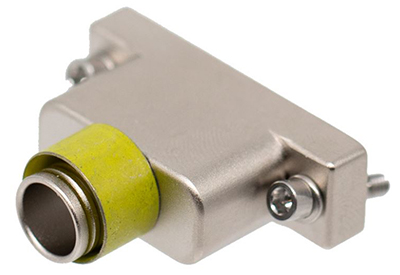

Safety laser scanners like the Omron OS32C are photoelectric barriers with rotating lasers that can be programmed to guard irregularly shaped areas. A stop signal is initiated when an object is detected in the hazard zone, and warning zones are available to alert personnel when they’re coming close.

The benefits of using safety scanners is that they permit easy and safe access to hazardous areas for repetitive operations while enabling the manufacturer to set up multiple warning zones and safety zones using a single device. Furthermore, they’re easy to replace or repair with minimal machine downtime.

One of the greatest plusses of using safety scanners is their flexibility. If you relocate an application or modify a machine, it’s simple to adjust the scanner’s safeguard area to fit the new layout. Safety scanners also expedite troubleshooting, facilitate data collection and reduce overall machine downtime with status safety indicators that easily identify blocked areas.

If you’re looking to safeguard larger areas or those with complex shapes, it’s likely that a safety scanner will fit your application better.

![]()

https://automation.omron.com/en/us/blog/safety-scanner-versus-safety-mats-blog