Three Southwire Sites Receive The Copper Mark

December 15, 2023

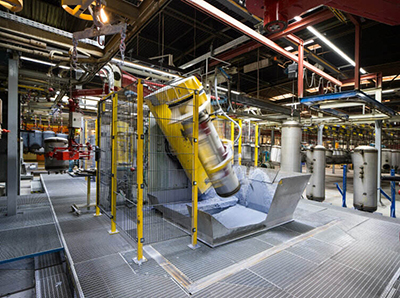

The Copper Mark, a major assurance framework for promoting the responsible production, sourcing and recycling of metals, has recently announced the certification of three Southwire facilities: those in Denton, Texas; Bremen, Ind.; and Lafayette, Ind.

“Receiving The Copper Mark at our manufacturing plants in Denton, Bremen and Lafayette is an incredible accomplishment and speaks to Southwire’s commitment to sustainability now and in the future,” said Burt Fealing, executive vice president, general counsel and chief sustainability officer at Southwire. “It also speaks to the dedication our team members have to our five core tenets of Growing Green, Living Well, Giving Back, Doing Right and Building Worth, which these facilities demonstrated throughout the assurance process.”

Southwire signed letters of commitment with the Copper Mark in February, beginning the assurance process for these sites and signaling the company’s intent to meet all applicable standards within 24 months.

Achieving The Copper Mark demonstrates the highest standard of responsible production in the copper industry, a commitment to continuous improvement, and contribution toward the UN Sustainable Development Goals. As the largest consumer of copper in North America, Southwire is dedicated to promoting transparency and accountability in the production of copper, especially given its critical role in the transition to a low-carbon economy.

“Congratulation to Southwire on this achievement,” said Michèle Brülhart, executive director of the Copper Mark. “With the company’s facilities in Denton, Bremen and Lafayette achieving The Copper Mark, Southwire is building important connections along the value chain to ensure copper is responsibly produced. We are grateful for Southwire’s engagement with and commitment to the Copper Mark and look forward to continuing our partnership to encourage responsible copper value chains.”

According to the organization, the Denton, Bremen and Lafayette facilities were awarded The Copper Mark certification, which is valid for three years, for implementing policies and practices that conform to the Copper Mark Responsible Production Criteria.

These criteria cover a variety of environmental, social and governance topics, including Community Health and Safety, Discrimination, Gender Equality, Working Hours, Greenhouse Gas Emissions, Energy Consumption and more.

“Thank you to everyone at these three sites for helping us reach this milestone,” said Charlie Murrah, executive vice president and chief supply chain officer at Southwire. “The efforts of those involved before, during and even after the assurance process show others within our industry that we mean what we say when it comes to sustainability, and receiving The Copper Mark communicates our collective commitment to benefit our stakeholders and add value throughout the copper supply chain.”

Southwire plans to continue certifying all U.S. plants that process copper over the coming years.