Extreme Environments in Industrial Settings: Learn More with nVent

May 28, 2024

For businesses involved in large-scale industrial operations, understanding the effects of extreme environments is essential. Having a good understanding of the potential hazards offers companies the opportunity to better protect their equipment, their people, and their products. This webinar, presented by Clay Cameron, Global Product Specialist at nVent, offers a comprehensive exploration into the unique challenges and solutions associated with industrial settings that are exposed to harsh conditions.

The webinar is designed for professionals in the industrial sector, safety experts, facility managers, product designers, and business leaders. If you’re aiming to optimize operations, enhance safety protocols, and implement best practices in challenging conditions you will find the information presented here very helpful.

Whether you’re directly involved in industries operating under extreme conditions or just seeking a deeper understanding of the broader implications for business continuity and safety, this webinar provides a detailed perspective to inform and guide your business strategies.

Understanding Extreme Environments:

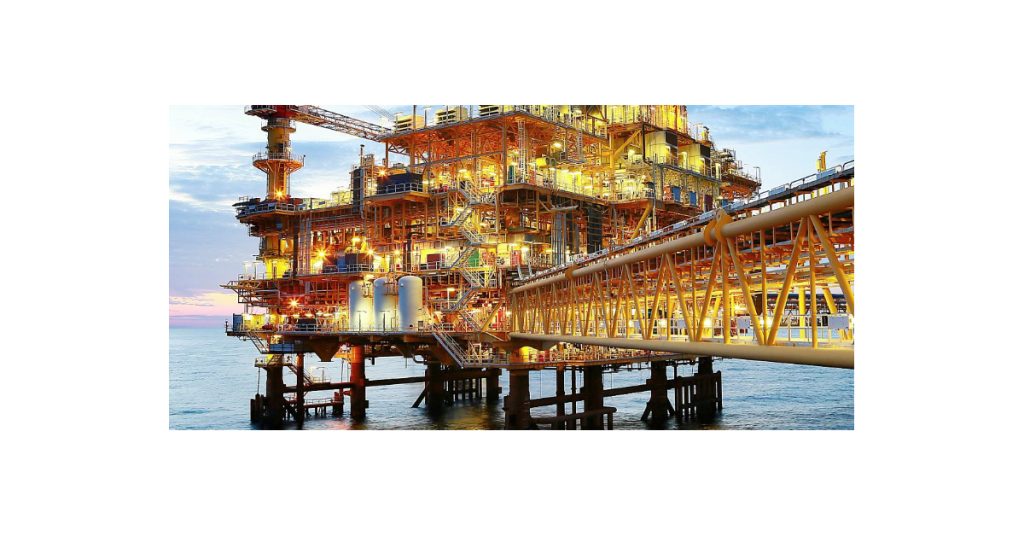

When we speak of extreme environments, we mean those that extend beyond the conventional challenges of high temperatures or pressures. These include areas exposed to corrosive elements like hydrogen sulfide, acids, and hydrocarbons. Additionally, they include settings with specific design needs, like offshore and coastal regions, moisture-rich areas, and those with high wind gusts or seawater impacts. Recognizing the specific challenges of these environments is the first step toward ensuring operational efficiency and safety.

What are the Challenges in Extreme Environments?

Industries operating in these conditions face a spectrum of challenges:

- Corrosion: Prolonged exposure to elements like Hydrogen Sulfide can lead to accelerated corrosion, especially impacting yellow metals and solder points.

- Material Selection: The importance of selecting corrosion-resistant materials, such as specialized stainless-steel variants, is heightened in these settings.

- Sanitary Design: Adhering to sanitary design specifications is vital, especially in environments exposed to aggressive corrosive agents.

- Gasket Integrity: Gaskets, essential for equipment sealing, can be compromised in extreme environments due to factors like chlorine exposure or acid accumulation.

“Deep understanding of the environment is the foundation of ensuring safety and operational excellence. Preparedness isn’t a luxury; it’s an imperative.” – Clay Cameron, Global Product Specialist, nVent

Key Technical Insights:

- Enclosure Elements: The webinar delves into the importance of enclosure elements in extreme environments, emphasizing the right material choice, robust & and removable designs, and the significance of seepage and door openings.

- Hinging and Latching: Cameron discusses the challenges associated with hinging, especially with painted mild steel, and the importance of effective latching in water treatment plants.

- Internal Componentry: The session highlights the role of internal componentry, touching upon issues like tinned copper wiring in cabinets experiencing sulfur corrosion.

The nVent Advantage:

nVent provides equipment solutions tailored for extreme environments. Their offerings range from robust enclosures with replaceable gaskets to products ensuring sanitary design specifications. With a focus on detail, from material selection to design, nVent products offer longevity and reliability in even the harshest conditions.

How Can nVent and Graybar Assist?

For a deeper understanding of extreme environments and to explore the range of solutions nVent offers, Graybar invites you to view the full webinar, now available on demand.

https://www.graybar.com/extreme-environments-in-industrial-settings-learn-more-with-nvent