What’s New with PILZ in 2022?

April 18, 2022

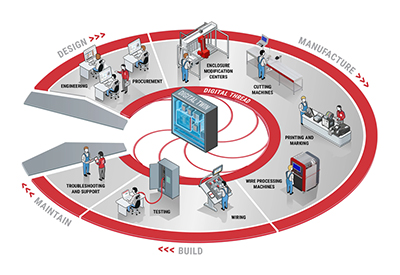

What’s new in 2022 for your automation solutions? In a word, lots! Pilz provides automation solutions for plant and machinery: complete and simple. From sensor technology to control and drive technology – safety and automation included. Various software tools enable simple operation and make commissioning easier. Benefit from short downtimes and high plant availability due to extensive diagnostic options.

Here PILZ presents their product innovations for 2022 for your safe automation. Click on the titles to download your copy of the brochure.

Safe monitoring of the cardboard feed on packaging machines: Increase the safety and productivity of your packaging machines! This Pilz solution is used in the cardboard feed to prevent an operator from reaching into the machine through the empty material feed opening and being injured.

The world’s first UL-certified Type 3 safety light curtains PSENopt II: The safety light curtains PSENoptII Type 3 are the first in the world to receive certification from the global test organization Underwriters Laboratories (UL).

Safe protection zone monitoring, even for robotic applications: PSENradar and PNOZmulti2: The new radar sensor PSENrd1.2 and the new analysis unit PSENrd1.x. Thanks to the high safety category Cat.3/PLd, not only outdoor applications and areas in wood and metal processing are safe-guarded, but now also robot applications. With the new self-teaching background function, changes can now be made within the warning or protection zone during operation without requiring a new configuration.

Safe small controllers PNOZmulti 2 –modular for simple applications: Do you need to monitor a moderate number of safety functions on your machine? The new base unit PNOZmB0.1 can be used as a stand-alone or modularly expanded with a maximum of one I/O module.

Safe small controllers PNOZmulti Configurator –new full version 11: New Version 11 builds upon a new software architecture with higher performance. The software tool thus offers state-of-the-art safety and continues to act as a benchmark for safety software.

Safe motion – new motion monitoring functions for drive-integrated safety!: The new safety card PMCprotego S3 expands the drive-integrated solution and allows the application-specific error response to be adapted so flexibly that the highest productivity of the plant is achieved in each case under themost varied safety requirements.

I/O module with protection type IP67 and PROFINET/PROFIsafe: The new PDP67PN with PROFINET/PROFIsafe interface is the ideal solution for safety outside the control cabinet. Thanks to its robust design with protection class IP67, it can be installed directly at the machine. This saves space in the control cabinet and enables modular plant designs.

Safe automation of AGVs: The safety laser scanner PSENscan delivers surface monitoring and the provision of data for the navigation of mobile platforms. Adjustment of the dynamic protected field is performed by directly analyzing the encoder inputs in the laser scanner.

Safe operation of AGVs: We make your AGV application safe. In every way possible! Benefit from our complete service package including a Design Risk Assessment (DRA), Factory Acceptance Test (FAT) and a Site Acceptance Test (SAT). Pilz also offers a training couse regarding the safety of AGV systems.

CEFS – Certified Expert in Functional Safety: This training course gives you expert knowledge of functional safety of machines that you can put to immediate use.

For more information on any of these products or services, please contact your Pilz Sales Representive.

![]()