Pilz: Clearing The Way For Cylinder Production

September 21, 2021

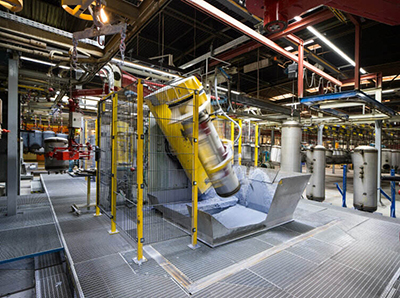

54 plants are to be modernised, to upgrade Vaillant’s production of hot water storage cylinders to state-of-the-art electrical and safety technology. The safety design for cylinder production was to incorporate a barrier-free solution for two older production lines, combining safety with efficiency. The loading and unloading area presented a challenge, as it was to be free of any disruptive structures.

Safety that’s almost artistic

On the basis of the hazard assessment Pilz developed an unusual safety solution using the light curtains PSENopt II. The individual positioners are accessible from three sides and secure cylinders of various sizes, which are fed in manually and via crane. Pilz supported the modernisation process in a spirit of partnership, from the hazard assessment, safety concept and safety design through to system implementation. The solution was found during a joint workshop: the light curtains PSENopt II were tilted ninety degrees, the transmitter was embedded horizontally into the floor and the receivers were installed on the ceiling. That way it was possible tor the exchange between human and machine to be free from barriers, without compromising safety. The safe configurable small controller PNOZmulti 2 manages all the safety-related signals. Should a plant operator interrupt the light beams transmitted from the floor or step on one of the upstream pressure-sensitive mats, PNOZmulti 2 will trigger an immediate safe stop of the hazardous movement – with no barriers in sight!

The benefits at a glance

Allows older production lines to be operated safely and in compliance with the standards for further years to come

Barrier-free safety solution offers higher productivity and greater freedom of movement for operators

Based on the configurable small controller PNOZmulti 2, expansion modules can be used to extend the system individually

![]()