Automate-X Counts on Beckhoff for State-of-the-Art Tank Farm in New Zealand

September 21, 2021

Innovative solution for hazardous areas

The New Zealand system integrator, Automate-X, has used Beckhoff components to automate the tank farms of a leading global operator. Its aim was to create an efficient interface between ship and shore while also facilitating agile and competitive supply chains. The result is state-of-the-art terminals that provide the tank farm operator’s customers with consistently high quality and safety without compromising on comprehensive environmental protection.

The purpose of tank farms is to provide a safe environment for the storage for chemicals. Various raw materials such as gasoline, crude oil, liquefied natural gas, heavy oil, naphtha, and other liquid chemicals are temporarily stored here while they wait to be transported by ship, rail, tank truck, or pipeline for further use or processing. With this in mind, large tank farms are often located near oil production areas, petroleum refineries, chemical industry sites, large ports, and major transshipment points.

Chemicals pose a special challenge

As the new tank farms for the global operator in New Zealand have been designed to store flammable chemicals, they are classified as plants with high hazard potential. This poses special challenges for both the tank farm operator and the system integrator, as there are stringent requirements regarding automation when storing potentially explosive and environmentally harmful chemicals. For this reason, the engineers at Automate-X had to take into account numerous aspects, standards, and special features of explosion protection, as well as functional safety, when planning the automation concept. They were also required to carry out a comprehensive analysis of the electrical and safety-related requirements. In the explosion protection zone, for example, the hazardous areas had to be defined to allow suitable explosion-proof components to be selected. Another factor to consider is that a high level of plant availability had to be achieved to prevent a dangerous situation caused by a plant breakdown.

“We came up with the solution of implementing a dedicated control system based on remote I/O couplers connected throughout the plant by EtherCAT. All safety-critical elements are monitored and controlled via a CX5130 running TwinSAFE, and as a final safeguard against overfilling, the storage tanks are equipped with SIL3-certified vibrating fork probes,” reports Marcel van Niekerk from Automate-X. He goes on to explain that: “The gantry area for loading the tankers features infrared flame detectors that can trigger a spray foam system in the event of a fire to prevent a potentially catastrophic event. Additional safety components include emergency stop switches, NAMUR sensors to monitor valve statuses, and a connection to fire alarm systems.” In addition to the safety control system, Automate-X also installed a separate CX5130 that handles a number of tasks including regulating the control of pumps and valves.

Countless benefits for customers

It didn’t take long for the company to decide in favor of Beckhoff – and therefore PC-based control technology – because the open nature of the technology developed by Beckhoff facilitates straightforward integration of third-party software and hardware. This meant the Ignition SCADA software platform could be incorporated into the tank farm project, and the tank farm operator’s existing drives were integrated into the automation system via EtherNET/IP.

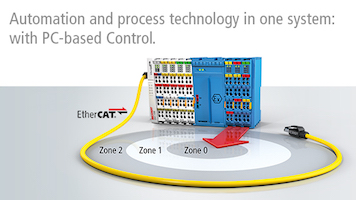

Another key advantage for the project is the wide range of Beckhoff terminals, since the modular EtherCAT I/Os allow for the integration of safety, communication, redundancy, and explosion protection components in a single system. “On a single I/O platform, we can accommodate digital I/O modules, TwinSAFE, analog Ex inputs, NAMUR inputs, HARTs, and RS232/RS485 – all running on EtherCAT. Not only does the EtherCAT redundancy ensure a very high level of availability, but no other platform offers such flexible configuration options,” explains Ben Haughey from Automate-X.

Intrinsically safe barriers are not required due to the use of the EtherCAT terminals in the ELX series that feature intrinsically safe interfaces. This serves to simplify the electrical design significantly and makes it possible to achieve high-resolution, high-precision signal acquisition in hazardous areas, which is already standard in non-hazardous areas. The use of EtherCAT single-mode fiber-optic components enables interference-free communication between the tank farm operator’s extensive plant sections. In addition, the implementation of cable redundancy via a ring topology is also possible via fiber optics to ensure a high level of plant availability.

Communication between the various controllers and the Ignition SCADA system is implemented using OPC UA. Operators can access the SCADA system using intrinsically safe tablets, allowing them to call up plant data and control the plant from anywhere on site. Communication between TwinCAT and SCADA is seamless via the TwinCAT OPC UA standard.

“We are delighted that we have been able to implement an innovative and, above all, consistent automation concept for the tank farms using Beckhoff components specifically for hazardous areas. Our customer can benefit from a reliable solution that is sure to stand the test of time,” reports Marcel van Niekerk.

Components used

Automation

- TwinCAT PLC

- TwinCAT OPC UA

- TwinCAT cable redundancy

IPC

- CX5130 embedded PCs

I/O

- EtherCAT ELX terminals

- EtherCAT EL terminals

- EtherCAT single-mode fibre optics

- TwinSAFE terminals

- EtherNET/IP master terminal

![]()