Partnership Brings Innovative Automated Filtration System to Croatian Brewery

August 17, 2020

Parker Hannifin was recently pleased to announce that the Zagrebačka pivovara brewery in Zagreb, Croatia is benefitting from innovative new filtration technology, thanks to a partnership with Agidens Process Automation.

Zagrebačka pivovara, which is part of Molson Coors, commissioned Belgium-based Agidens Process Automation to implement a Cold Stabilisation Module (CSM) at its brewery site. The brewery wanted to expand its range with a premium, non-pasteurised lager, and commissioned Agidens Process Automation because of its proven expertise in cold stabilisation technology.

The CSM uses Parker Bioscience Filtration’s PREPOR NG and BEVPOR BR filters to achieve microbial stability, whilst protecting the taste characteristics of the premium lager. The installed system filters, on average, 250 hectolitres of beer per hour.

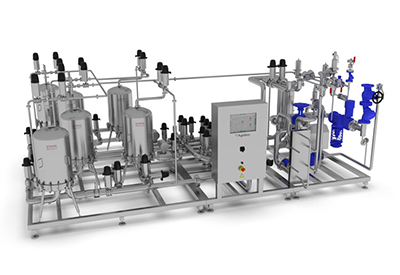

In just five months, Agidens’ engineering team was able to provide a tailor-made CSM system, which was integrated into the brewery’s existing production line. The installation consists of three modules: a filtration skid, a distribution cluster and a Clean-In-Place (CIP) skid – which totals 6.75m in length.

As the site was only accessible via a small elevator, the CSM had to be custom designed. Once constructed, it was disassembled for transportation to the brewery, and re-built for installation.

Parker Bioscience Filtration’s BEVPOR BR range of filters features a unique Polyethersulphone (PES) membrane, which offers a long service life. This contributes to efficient and low cost of operation filtration of beer in sterile environments. The PREPOR NG filters are used to remove yeast and particulate, such as filter aids and haze components. The high level of retention ensures that a consistent quality of brew is delivered and provides a greater level of membrane filter protection during cold stabilisation.

Sterile filtration solutions provided by Parker Bioscience Filtration are designed to allow brewers to reduce the cost of microbial stabilisation, while protecting the beer’s sensory appeal.

Lee Pattison, Product Manager – Food & Beverage at Parker Bioscience Filtration, said: “We are delighted that our partnership with Agidens Process Automation has been able to create an effective solution for Zagrebačka pivovara. “It is an example of how breweries are able to tap into Parker Bioscience Filtration and Agidens Process Automation’s combined expertise to access innovative sterile filtration technology.

“By switching from pasteurisation to cold stabilisation, breweries can reduce product losses and energy costs, while protect taste from the effects of heat treatment and increase shelf life.”

Tomislav Rorbach, Process Optimisation Engineer at Zagrebačka pivovara, said: “The cooperation with Agidens was flawless and they have fully met our expectations with their CSM module.”

Parker Bioscience Filtration has five decades of experience in working with the food and beverage sector.

In addition to the brewing industry, it has specialist expertise in the dairy, bottled water and wine industries, and supports companies in improving process control, efficiency and security throughout their production and packaging processes.

![]()