Emerson and MHPS Collaborate on Power Industry Digital Transformation

August 4, 2020

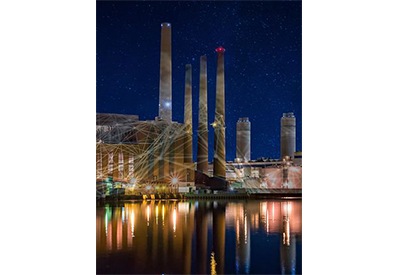

Emerson and Mitsubishi Hitachi Power Systems Americas have recently joined forces again to develop digital technologies, software and services to help utility customers drive operational excellence in North America. The companies will collaborate on digital solutions to optimize performance and reliability, enable predictive and AI-driven maintenance strategies, and automate operational decision-making.

The collaboration will build on the expertise of Emerson and MHPS to enhance the performance and reliability of power plants operating with MHPS gas or steam turbines.

Emerson’s Ovation automation technologies, software and solutions portfolio for power generation is highly regarded in the industry, controlling thousands of plants across the globe. Its embedded digital twin enables power plants to identify and implement new operating efficiencies, improve safety, decrease unscheduled maintenance and train workers.

As a leading global provider of power generation and energy storage solutions, MHPS is driving the development of next-generation power plants and digital solutions that deliver higher efficiencies to reduce carbon emissions and the highest levels of reliability to lower maintenance costs. Its industry-known MHPS-TOMONI digital solutions platform provides real-time adaptive control and actionable knowledge to optimize plant performance and significantly improve reliability.

“Emerson has worked collaboratively with MHPS for over a decade to bring the best experts, technologies and services to the power generation industry,” said Bob Yeager, president of Emerson’s power and water solutions business. “This next chapter will focus on identifying and delivering the best digital transformation strategies and technologies that will drive operational performance for our customers and create cleaner, more reliable power for consumers.”

The two companies will explore these and other advanced technologies: advanced sensing; thermal, process and equipment modeling and diagnostics; advanced control; analytics; pattern recognition; remote monitoring; digital twin; automated workflows; and AI-driven predictive maintenance.

One of the companies’ collaborations is to build and deploy the next generation of total plant simulation for the Intermountain Power Plant Renewal project. “This collaboration leverages Emerson’s digital twin technology, MHPS’ high-fidelity gas turbine and steam turbine models, and advanced analytics. The simulation solution will seamlessly receive data and operate in parallel with the plant’s integrated control systems and other enterprise platforms to support commissioning and training,” said Marco Sanchez, vice president of intelligent solutions at MHPS.

Paul Browning, president and CEO of MHPS Americas and chief regional officer for Europe, Africa, the Middle East and the Americas, said, “MHPS looks forward to this next stage of collaboration with Emerson as we continue developing digital solutions that will enable our customers to provide affordable and reliable electricity, maximize profitability of existing and future power plants, and combat climate change. Together with Emerson and our customers, we will achieve a Change in Power.”

![]()

https://www.emerson.com/en-us/news/automation/20-08-mhps-power-collaboration