Siemens’ Tips for Panel Builders Series – Part 6: Determining the Overall SCCR of an Industrial Control Panel for UL

November 3, 2020

Machines, their control panels, and other types of electrical equipment must be designed and sized in accordance with their location of installation. This ensures protection against the damaging effects of a short-circuit in the electrical equipment.

In the US there is a legal requirement to determine the short-circuit current rating (SCCR) of an industrial control panel.

Did you know it is the responsibility of the user to calculate and determine the maximum available short-circuit current at the connection point (point of incoming supply)?

Unless otherwise agreed, a short-circuit at the incoming supply terminal is the responsibility of the user. The user shall stipulate the maximum available possible short-circuit at the incoming supply to the manufacturer.

Control panels are individually designed for specific applications

Short-circuit-based configuration of the industrial control panel shall be performed by the manufacturer. The industrial control panel shall be designed so that it supports the specified SCCR. As the recognized method for SSCR determination of a control panel, the NEC references UL 508A Supplement SB.

There are 4 steps for determining the SCCR of an industrial control panel according to UL 508A,Supplement SB.

Tips for you!

Determination of the SCCRs of built-in components

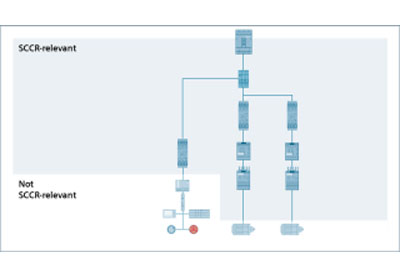

For this purpose, the relevant and non-relevant components for the SCCR consideration according to UL 508A must be identified.

In accordance with Supplement SB4.2, apart from certain exceptions, all components in the power circuit shall be considered when determining the SCCR and shall express an SCCR in amperes or kiloamperes with specification of the voltage.

The overall SCCR for the control panel is determined by the weakest SCCR value of the components.

a. Device markings or data sheets

The determination of the SCCR for all components is based either on device markings or component data sheets supplied by the manufacturer of the components.

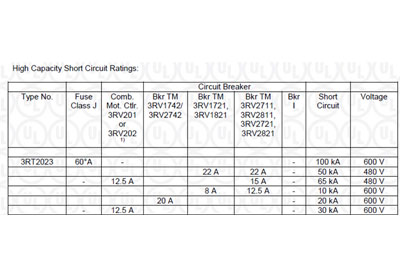

b. UL 508A, Table SB4.1, for components without SCCR marking

If no information is at hand, Table SB4.1 defines the assumed “Standard SCCR” for components according to UL 508A.

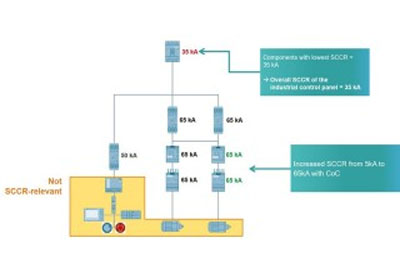

c. If required – increase the SCCR through use of tested combinations

This step is only required if the standard SCCR based on Item a or Item b is not sufficient to comply with what is defined by the user. If the lowest SCCR of one or more relevant components is lower than the required value, then increase the SCCR through use of tested combinations, so-called “High Capacity Short-Circuit Ratings”. This can be found in the “UL Certificate of Compliance” (CoC).

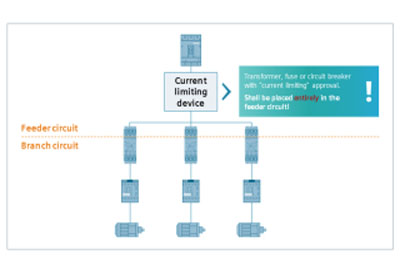

If required — increase the overall SCCR of the control panel by using current limiting devices in the feeder circuit.

In accordance with UL 508A, Supplement SB4.3, the maximum possible short-circuit current for components of the power circuit can be reduced by using current-limiting devices in the feeder circuit. It is imperative here, however, that the current-limiting devices are situated entirely within the feeder circuit.

Determing the overall SCCR of the control panel as specified in SB4.4.

Determine the overall SCCR for the industrial control panel after the required measures have been established.

The overall SCCR for the control panel is determined by the weakest SCCR value of the component after the required and selected measures have been applied. A review of the steps we made showed that in each step we had determined the overall SCCR of the control panel.

Simplfy the determination of the different scenarios in which the SCCR of separate components is increased.

Use high SCCR values of tested combinations!

Instead of thinking about how to limit the current or which device can be used, or even thinking about paying more for a device with higher “Standard SCCR”, we recommend to use tested combinations.

When you use the “Standard SCCR” values of individual components, especially motor controllers and overload protection devices, you may end up with an industrial control panel that can only hold up to 5kA, 10kA, or even 15kA. The issue with these low values is that often industrial control panels will need to have an overall SCCR higher than any of these values.

The Siemens portfolio has been tested in accordance with the performance requirements, including short circuit requirements, and this includes the high fault current combination test. You will find also type 1 and type 2 test combinations on the certifications (CoC=Certificate of compliance).

Our TIA Selection Tool tool can be used to select the UL test combinations with a small amount of input. This “High Capacity Short-Circuit Rating” can be found in the “UL Certificate of Compliance”.

With the use of the CoC we can increase the critical product’s SSCR through use of tested combinations, or “High Capacity Short-Circuit Ratings”.

You will find more information on these links

Click here for more information.