Siemens’ Tips for Panel Builders Series – Part 2: Class 2 Power Supplies for 24V DC Circuits

September 8, 2020

When control equipment is used in the U.S., the UL standards have to be complied with in respect of safety and fire protection. The standards-compliant configuration of the control panel plays a major role here. Control circuits according to NEC Class 2 must be limited in power to 100 VA. By selecting the right power supply and fuse protection, acceptance can be simplified significantly and costs can also be saved.

Practical tips for you!

Every item of control equipment is checked and approved in the U.S. by the competent AHJ inspector (Authority Having Jurisdiction). The AHJ inspector does not have to accept the components in safe NEC Class 2 control circuits (UL 508 § 2.7) which is why non-listed UL devices may also be used. On the other hand, components with the approval “…for use with Class 2 only…” shall only be connected to NEC Class 2 circuits. An NEC Class 2 control circuit may be fed out of the control panel if it is marked at the terminals for that purpose and is laid separately to other circuits.

Control circuits according to NEC Class 2 can be implemented with various concepts:

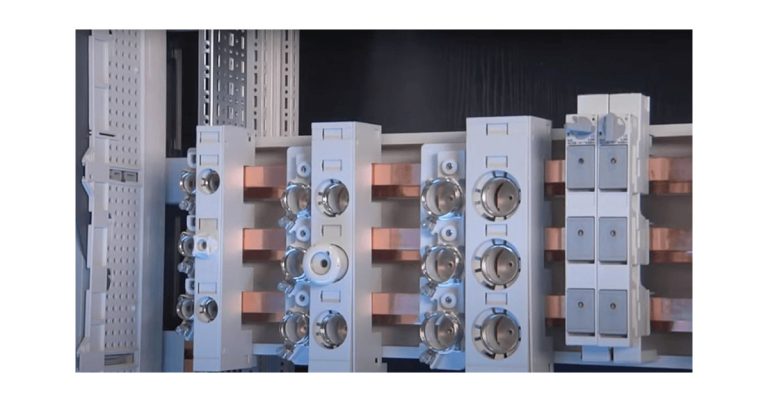

The Conventional Version: Use of NEC Class 2 Power Supplies

Power supplies according to NEC Class 2 are characterized by the fact that the output power is limited to 100 VA even if a fault occurs. A power supply unit is required with multiple control circuits. If the system is expanded, an NEC Class 2 control circuit can easily be implemented by means of an additional power supply unit.

The Version for High Availability: Redundancy Modules with Power Limitation

When SITOP redundancy modules are used with NEC Class 2 output, more powerful central power supply units can be used as they limit the power to max. 100 VA. Connection is made either at one power supply in order to distribute the 24 V supply only to NEC Class 2 feeders, or at two central power supplies to additionally ensure a higher availability of the 24 V supply. In this case, the redundancy module decouples the two power supply units and, if one power supply unit fails, the redundancy module supplies the control circuit via the intact power supply unit.

The Version with Integrated Cable Protection: Selectivity Modules with Multiple NEC Class 2 Outputs

NEC Class 2 load feeders can also be implemented with special selectivity modules. In this case, a central 24 V DC power supply feeds one or multiple selectivity modules, the output channels of which are limited to a power of 100 VA. The advantage of this configuration is that both the power limitation to NEC Class 2 and selective protection of the outputs against overload or short circuit can be implemented. A faulty feeder is immediately de-energized and all other feeders continue to be supplied without interruption. Even a PLC that bridges a power failure for just a few milliseconds continues to run without any problem. When SITOP NEC Class 2 selectivity modules are used no additional short-circuit protection devices have to be installed in the four NEC Class 2 feeders.