Skid-Based Production is Manufacturing’s “New Normal”

July 13, 2020

Whether it is for hand sanitizer, shampoo ingredients, a medical additive, or any of a thousand other process steps in a thousand different industries, producing chemistries and other products in a modular platform is increasingly the norm. More and more frequently Optimation are seeing requests, and opportunities, for modular or skid-based production and manufacturing process projects. These are condensed application sets embodied in a well-controlled and highly-engineered custom configuration. Clients come to them for these skid systems, or they propose them, based on an understanding of the process requirements. These technologies are ideal to make the most efficient use of space, or to optimize and simplify set up and installation, and/or to produce repeatable systems that can be transported or installed virtually anywhere.

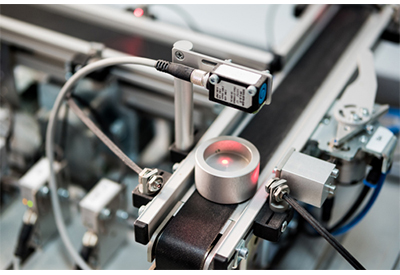

These systems can come in a variety of configurations. Most often, they are mounted on a frame or sled of some kind, upon which various sub-systems or process components are mounted and interconnected. These include transport and material handling, fluids and powders storage and dispensing, raw materials or product stock, and more. Nearly always there are utility connections such as power, air, gases, water, and so forth that are usually designed to be quickly connected with pre-engineered fittings that enable rapid and easy set up. This designed-in flexibility and agility makes skids an ideal form factor for any number of process add-ons or standalone implementations.

Sometimes however, the footprint and profiles need to be different than a traditional skid which can take up floor space that might be in short and pricey supply. Criteria might drive a vertically-mounted panel or plate with an open-air set of components mounted on the back plane. The same general principles apply as above. That is, quick connect utilities, plumbing, etc. totally packaged and highly-engineered configurations that are purpose-designed, robust, and rapidly deploy-able. These are commonly pre-fabricated in full at Optimation and then delivered for final installation and test at the user’s site.

Alternatively, conditions may require that the equipment be housed in a protective enclosure, which some often refer to as a “pod.” This could be to protect the gear and/or the process from the elements. Or, it could be to secure the equipment and the contents for safety reasons–be they environmental, worker safety, product quality, process sensitivity, and so on. A shipping container can be re-purposed and employed as such an enclosure, providing a sealed environment to accommodate high-pressure testing systems such as oil and gas test support. This affords a neatly packaged, ready-to-install over-the-road-(or ocean)-ready means to deliver a tested and functional system right to the doorstep of where it is needed. Cost-effectively. Optimation have designed and built many dozens of these highly engineered systems and delivered them domestically and around the world. Some are rather spartan, for pure basic utility; others have commissioned us to fabricate high-end systems that are both comfortable to work in (paneling, hardwood floors, climate controlled, etc.) as well as featuring state-of-the-art technologies inside.

When the needs of an application dictate a non-stationary solution then the optimal case is to build the equipment into a portable or transportable cart. This allows the equipment to be shared among multiple bays, test systems, or other applications sites in a plant or factory. These systems, generally more compact even then the panels, plates, and traditional skids, most often perform tests or deliver certain discrete operations to a bench or system. When equipped with a user interface and control system, a user can execute one or more tests or operations at multiple locations with a single skid. They can prove to be very economical, as well as provide numerous system support functions from a single platform.

Regardless of which embodiment you choose, these skid platform designs deliver significant performance and flexibility in a manner that can be custom engineered yet delivered cost-effectively and quickly. They have applications as diverse as medical product manufacturing, high-pressure test systems, food and beverage production, and chemical/petrochemical.

![]()

https://blog.optimation.us/skid-based-production-is-manufacturings-new-normal