Sustainable Wire Marking

January 5, 2024

Clear wire identification with different colors is essential for the fast and safe connection of cables and wires.

However, conventional marking methods also have disadvantages, such as environmental compatibility, for example. “Pastel B” is an alternative method for marking wire pairs in a more resource-efficient, low-CO2 and sustainable way.

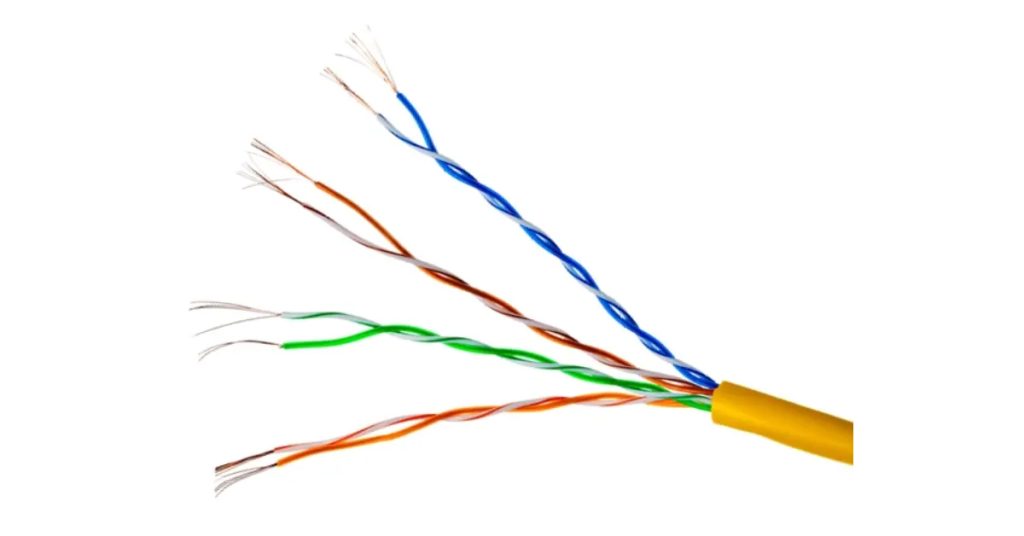

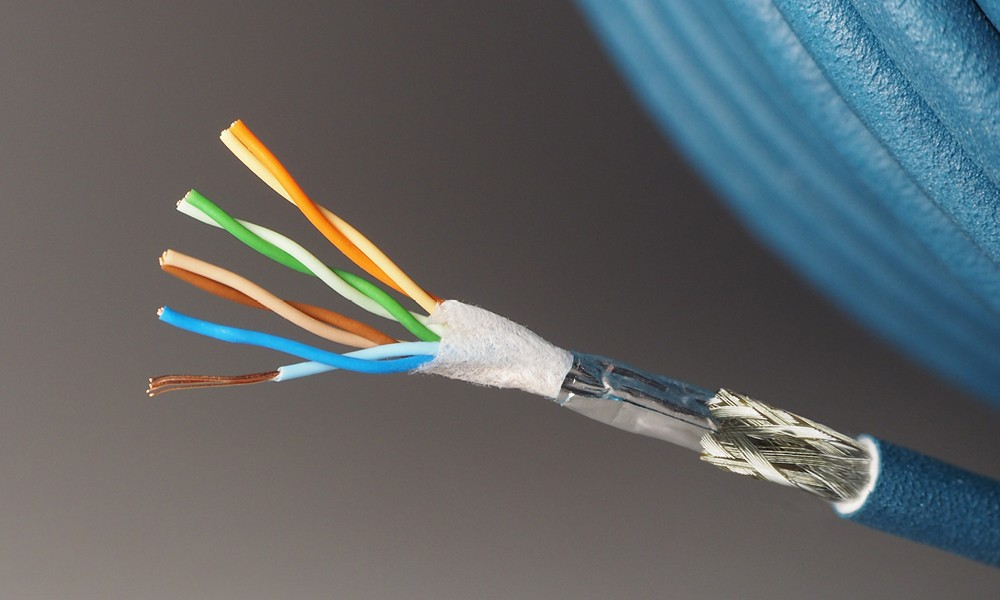

One potential application for the new marking method is four-pair data cables, such as those used in Ethernet cabling. In these cables, each pair of wires has an A and a B wire, which are color-coded for easy identification. The colors are standardised and defined as follows:

- Green / Green-white

- Orange / Orange-white

- Blue / Blue-white

- Brown / Brown-white

The oldest method of marking two-color conductors is called ring marking. This involves spraying rings of the appropriate colour onto the existing white core insulation using a spray paint gun. However, the process is not very efficient. As with any spray painting process, 100 percent of the paint does not end up on the conductor, which means increased material consumption and CO2 emissions. The solvents in the paint can also cause unpleasant odors and, if inadequately extracted, can pose a health risk. In addition, some materials do not adhere well to the paint, making cable assembly more difficult and time-consuming.

A more modern option is to add an extruded green, orange, blue or brown longitudinal strip to the white conductor insulation. Like the insulation itself, this is made from plastic granules. Unlike painting, there is no odour or CO2 pollution and the paint cannot be smeared. However, this process requires an additional strip extruder, which means additional investment costs and higher energy consumption.

In the future, however, an alternative process could help to make wire marking, and thus the entire cable production process, more resource- and energy-efficient and overall more environmentally friendly. Called the “Pastel B” process, a white B concuctor is not marked with a colored stripe or ring, but the entire conductor insulation is produced in a color that corresponds to the A conductore, but is significantly lighter. For example, the conductor pairs are light and dark green or light and dark blue, and can clearly be distinguished.

The strengths of the Pastel B process: No varnishes or solvents are used meaning no chemicals are released into the environment during application. The process can be carried out on standard extruders with a color feeder, without the need for an additional strip extruder. This reduces both the investment cost and the power consumption. Projections have shown that the use of Pastel B can reduce CO2 emissions by around 15 percent, or around 20 tonnes per year for an average cable factory.

It also reduces the number of tools that need to be stored and maintained. The marking is clear, permanent and cannot be wiped off. This means that all the requirements for accurate wire marking are met – with significant benefits in terms of cost and sustainability.

There is also nothing in the IEC 11801-1, EN50288-7, ANSI TIA/EIA 568 and IEC 60304 standards applicable to cable manufacturing that prevents the use of the Pastel B process. There are other reasons why it is not yet in use: Primarily, users have long been accustomed to conventional marking methods, and secondly, customers want consistent marking across manufacturers, which is likely to make the transition a lengthy one.

A successful introduction could be accelerated if Pastel B is included in standardization and if national and international committees and associations become more involved in the process. Increasing demand from customers would also help to convince manufacturers and standardization of the new process. In any case, HELUKABEL sees great potential in Pastel B wire marking and is technically in a position to implement and offer it at its production sites without any problems.

https://www.helukabel.us/us-en/Newsroom/Item/conductor-identification-pastel-b.html