Speedier, More Productive Wiring Can Speed Up the Panel Shop

February 7, 2025

In today’s manufacturing landscape, the speed and reliability of daily operations translate directly into enhanced productivity.

Miles of wires underpin nearly every industrial operation, and those wires come together in control panels filled with tray after tray of connection terminals. Due to the high number of conductor termination points, there can be a higher susceptibility of signal loss or intermittence as a result of bad terminations. Any of these interruptions can reduce the ability to meet production goals, as downtime will be necessary until faults are corrected.

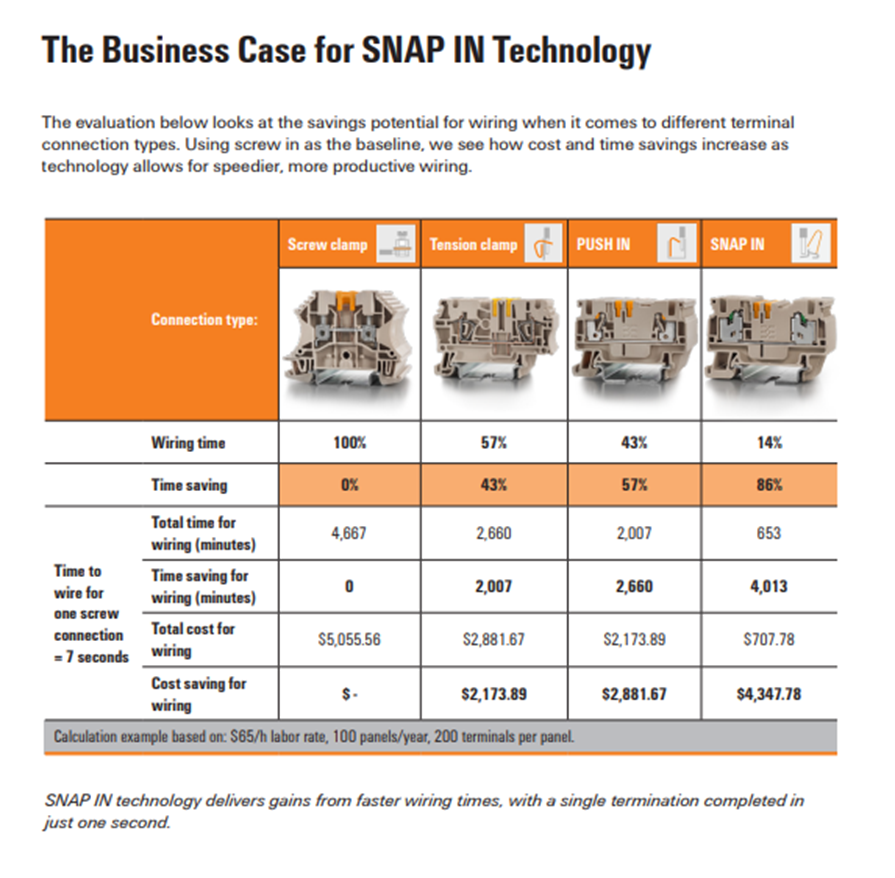

The evolution of connection technology has been one of continual improvements to achieve better time and cost savings. From the screw clamp and tension clamp to PUSH IN, design changes led to tool-free wiring. However, with SNAP IN design, panel builders could now experience one-handed, tool-free connectivity without the need of a ferrule – with a single termination completed in just one second.

Engineering a better spring design

Advancing to a faster, safer and more reliable terminal connection technology started with understanding at Weidmuller of the practical needs within a panel or system integrator shop. A team of product managers, developers and designers first analyzed control cabinet construction to identify potential improvements. An iterative process allowed the team to work through different challenges, including operating pressures that caused the mold to bend and abrasion issues with plastic parts rubbing on other plastic parts.

The team arrived at a new design tailored for terminal blocks. SNAP IN features a single metal strip that creates its own spring, which resolved previous bending and abrasion difficulties. That simplified design structure transferred to simplified production, because no additional or tiny plastic parts – some smaller than a plastic granule and so lightweight an air draft could blow them away – needed to be aligned perfectly for the connection to work.

The end design is a one-piece, self-holding metal spring – the heart of the SNAP IN clamp. Once a wire is fed into the opening and hits the pressure plate on the bottom, the spring mechanism is released. Once activated, it forms a self-contained force system that ensures the best and safest connection

Future-ready and faster than ever

SNAP IN meets every electrical requirement as other spring-type terminal blocks – such as widely accepted tension clamps or PUSH IN technology – and adds in ease of use. SNAP IN can be introduced with other connections in the same terminal cells. The unique snap mechanism and its special spring-geometry design are patented. But Weidmuller didn’t design SNAP IN solely for today’s needs. SNAP IN terminal blocks provide a scalable product for the transition to next-generation operations. With increasing developments and opportunities for industrial automation, switching to this connection technology positions companies to be “robot ready” – and capture exponential financial gains and faster operations.

With the introduction of SNAP IN technology, panel and machine builders have an innovative technology that is redesigning how control cabinets are constructed – leading to time savings, higher reliability and greater safety. More importantly, SNAP IN allows customers to act now and ready their wiring and signal transmission for automation, where they will benefit from exponential gains in effectiveness and efficiency, significantly enhancing their competitive advantage in their market.