Signal Marshalling: Primary Requirements & Critical Success Factors

October 1, 2024

By Hannah Witopil, Product Manager-Terminals, Cabinet Products Division (North America), Weidmuller USA

Signal marshalling plays a critical role in connecting instrumentation devices throughout large-scale industrial process plants via distributed control systems (DCS). It enables the reliable transmission of signals from thousands of distributed field devices like sensors, valves, and actuators back to the control room.

The long distances and sheer volume of signals in expansive process facilities make it impractical to connect field signals directly to control units or I/O modules. Signal marshalling provides an interface to group and bundle signals, routing them over common transmission paths. Terminal blocks installed in marshalling cabinets and junction boxes located throughout the plant collect and consolidate signals. The aggregated signals are then wired back to the DCS system in the control room.

Reliable signal connections are crucial for continuous monitoring and control of industrial processes. Any failures or noise in marshalled signals can disrupt production and potentially impact safety. As process plants often have lifecycles stretching over decades, the terminal blocks and connection hardware enabling signal marshalling must provide durable and dependable operation over many years of service.

Primary Requirements for Signal Marshalling

Signal marshalling solutions must be capable of collecting and routing thousands of process signals distributed across expansive industrial facilities. Terminal blocks consolidate signals from instruments wired throughout the plant and provide a bridge between the field devices and control systems.

Inside marshalling cabinets, terminal blocks serve several key functions:

- Feed-through terminal blocks provide basic point-to-point connectivity, transmitting instrument signals between the field and the control room I/O systems.

- Fuse terminal blocks protect signal circuits and devices by cutting power in the event of overcurrents. They prevent damage to downstream equipment.

- Disconnect terminal blocks open circuits to facilitate maintenance, testing, and commissioning. They isolate field wiring from the control side without disrupting running processes.

- Ground terminal blocks drain current surges and noise by providing a path to earth ground. Proper grounding enhances safety and prevents signal interference. Depending on one’s grounding philosophy, potential-free shielding concepts can be a requirement as an alternative to connecting the shield to PE.

In addition, marshalling terminal blocks must accommodate flexibility for last-minute engineering changes. Solutions allowing quick on-site function conversions, marking modifications, or layout adjustments avoid costly rewiring and unnecessary downtime. They facilitate necessary modifications as plants expand and upgrade over long lifecycles.

The combination of high density, mixed functionality, and adaptability in a terminal block solution allows efficient marshalling of mass volumes of signals in expansive process plants.

Critical Success Factors of Signal Marshalling

Several key factors determine the effectiveness of a signal marshalling solution for process facilities. The ideal terminal block products will maximize space and cost savings, simplify installation and maintenance, provide configuration flexibility, and deliver proven long-term reliability.

Space and Cost Savings

Terminal blocks designed specifically for marshalling applications optimize the use of limited cabinet space. Their compact construction, efficient form factor, and ability to condense multiple functions into a single block enables high-density wiring. These characteristics allow users to reduce the overall marshalling cabinet sizes or fit more signals into existing footprints. Smaller cabinets ultimately save material costs.

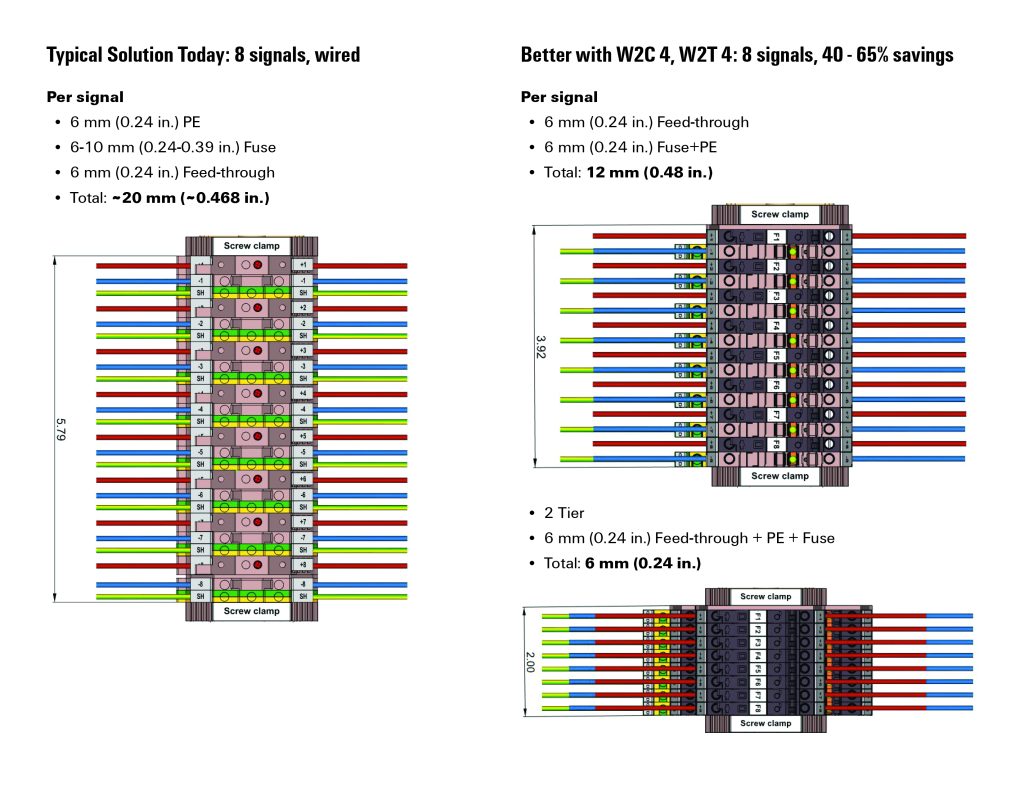

Advanced multi-tier terminal blocks, like Weidmuller’s W2C and W2T series, feature vertical stacking to marshal signals in a narrow 6mm width per signal. This design allows for up to 1,700 signal loops per meter of cabinet width, significantly outperforming traditional solutions. Combining functions like feed-through, fuse, or ground connections in one common housing also reduces part count over single-function units. The minimized hardware and footprint results in significant space savings and improved functionality.

Ease of Installation & Wiring

Installers benefit from streamlined terminal block portfolios employing uniform mounting footprints. Consistent dimensions and alignments allow for integrated marking schemes across all blocks. Shared accessories further simplify installations.

Leading-edge solutions, such as Weidmuller’s W2C and W2T series, offer a uniform footprint across all single-tier and two-tier versions. This consistency simplifies marking and wiring, reducing installation time and potential errors. In contrast, some competitors’ portfolios mix standard terminal blocks with specialized marshalling blocks, leading to misaligned marking channels and jumper connections.

As mentioned above, installers should look for multi-function terminal blocks that consolidate disconnects, fuses, grounding, and feed-through circuits into common housings. This greatly reduces wiring complexity compared to connecting separate single-function blocks.

Generous built-in marking channels, optional markers, and custom-etched plates clearly identify signals. Multiple cross-connection channels allow easy potential distribution and route signals to additional blocks. Advanced solutions, like Weidmuller’s, offer up to three cross-connection channels, providing greater flexibility in signal routing and potential distribution compared to the two channels typically found in traditional products.

Testing and Maintenance

Simplifying testing and maintenance saves considerable time and effort over the decades-long lifespan of a process plant. Terminal blocks that integrate standardized test points and sockets enable technicians to safely perform signal loop checks without disconnecting the wiring.

Products allowing quick on-site function conversions from disconnect blocks to fuse blocks prevent unnecessary rewiring. For example, installers can swap removable disconnect blades or fuse holders to change the protection mode.

Clear blown-fuse indication through LEDs reduces troubleshooting complexity. Importantly, advanced solutions like Weidmuller’s feature low leakage current circuits as standard across their fuse block range. This ensures that the visual indicator properly reflects the fuse status without creating a false signal. Other offerings on the market provide low leakage current only on specific, premium-priced models, potentially leading to inconsistent performance or increased costs.

Reliability and Durability

The terminal blocks performing signal marshalling must offer exceptional reliability and durability given the critical monitoring functions and 20+ year expected operating life. Screw clamp connections that are resistant to vibration surges maintain gas-tight connections and failure-proof signal continuity essential for safety and uptime.

Robust housings and sealing withstand demanding industrial conditions, high temperatures, moisture, and corrosive atmospheres. Approvals for hazardous environments also ensure suitability and compliance for process plant applications.

The long-term performance track record of terminal blocks provides assurance the products will continue functioning well beyond the initial commissioning phase without signal degradation over decades of operational lifetime. Their extended reliability ensures a wise infrastructure investment for plant and personnel safety.

In Conclusion

With such stringent demands, infrastructure components enabling signal marshalling should match the application’s needs. The terminal blocks’ specialized designs directly address the challenges around high density, mixed signals, and long-term dependability for critical links between field instrumentation and control systems. Careful terminal block selection streamlines marshalling cabinet builds while delivering safety and reliability over decades of industrial processes.

Visit HERE to learn about Weidmuller’s modular terminal blocks for signal marshalling.