How Row-Based Cooling Can Optimize the Performance of Small to Medium-Sized IT Installations

July 2, 2024

Small and medium-sized IT installations encounter some unique challenges when it comes to integrating IT cooling systems to maximize heat removal performance. To start, space constraints and the need for a more self-contained climate control footprint means network engineers need flexible solutions without sacrificing system performance.

But what further complicates choosing the right cooling infrastructure for small and medium-sized IT applications is the ability to remove high heat loads more effectively than other kinds of cooling systems.

This is where Rittal Liquid Cooling Packages (LCP) solutions help network engineers not only create more targeted cooling in IT environments with high-density heat loads, but the LCP design and engineering can also help companies significantly reduce their energy consumption and costs.

This article will look at a couple of key factors that liquid cooling packages can help optimize the performance of small to medium-sized IT applications, and how Rittal’s approach to LCP design can help network engineers create more efficient, cost-effective cooling.

Row-based cooling a closed-loop IT climate solution

Row-based cooling units are dedicated to individual rows of IT servers. Also referred to as in-row or closed-loop cooling systems, row-based climate control creates shorter airflow pathways compared to room or suite-based cooling systems, and row-based cooling pathways are also more defined and targeted to help ensure rows of IT enclosures maintain operating temperatures that provide consistent high levels of performance.

One of the important benefits of row-based IT cooling systems is the ability to vary the cooling output based on the rack density or thermal load of individual rows. For example, one row of server racks can run high density applications and an adjacent rack can run lower power density applications, and row-based cooling makes it possible to adjust cooling capacity to suit each row.

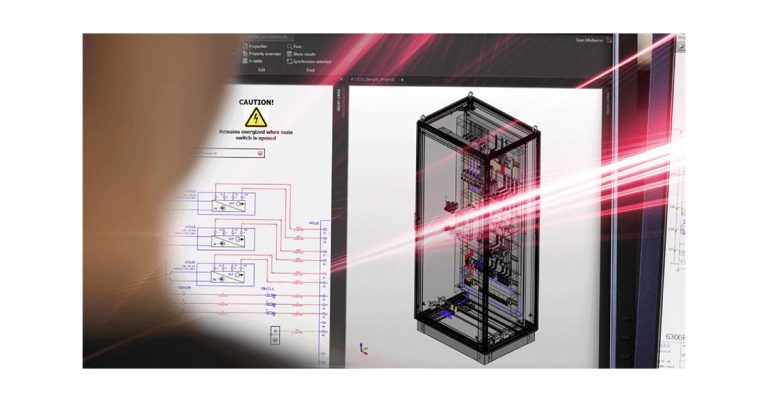

Rittal’s LCP solutions use a closed-loop IT cooling approach that removes high heat loads from greater equipment densities. What’s more, liquid cooling packages can be a more flexible, versatile solution to help network engineers adapt to challenging deployments. For example, Rittal’s modular LCP IT cooling units can be configured to support single or bayed IT enclosures, and front and rear unit access simplifies maintenance and troubleshooting tasks.

Row-based cooling can help reduce your infrastructure footprint

One of the top concerns for network engineers in small and medium-sized installations is the ability to reduce the overall footprint. While IT enclosures account for a large portion of this footprint, IT cooling units also play a major role in how much square footage is required for an individual application.

Rittal’s LCP cooling units can be easily scaled to meet demand without sacrificing targeted, precise airflows. This rapid scalability and rack-based configuration makes Rittal’s LCPs ideal for the increased level of IT computing in modern manufacturing — particularly with the rapid advancement of artificial intelligence (AI) systems in making predictions and decisions without human intervention.

In these applications, high thermal loads are commonplace, and network engineers need powerful cooling solutions that don’t waste precious floor space.

Row-based cooling can deliver energy cost savings

Creating adequate cooling for even small to medium-sized IT applications can be a costly proposition — especially as network engineers navigate the challenges of cooling specific IT racks as opposed to the entire data room. While most row-based cooling can provide some level of energy cost savings, Rittal’s liquid cooling packages can help network engineers reduce their energy consumption even further.

Aside from precise cooling outputs designed to target and control the temperature of specific IT racks, Rittal’s LCPs can deliver energy cost savings through:

- Reduction in fan power consumption

- Higher server inlet temperatures

- Elevated chill water supply temperatures

- Ability to use other facility water sources

- Reduction or elimination of air-cooled components

Plus, the use of EC fan technology and comprehensive software for local and remote monitoring, network notifications, and real-time cooling data and analytics help to ensure high performance on a 24/7 basis. Not only does this help network engineers create more efficient IT cooling, it also helps engineers create a more proactive approach to maintenance intervals, saving time, money, and resources.