Rethinking the DIY Approach to Automated Test Equipment Design

March 27, 2025

Developing in-house Automated Test Equipment (ATE) is costly and complex, diverting resources from core innovation. To address this, many companies outsource some or all ATE system design and development to third-party specialists.

In an industrial setting, developing Automated Test Equipment (ATE) in-house is often approached as a DIY (Do-It-Yourself) project involving the ambitious task of constructing a critical support system using internal engineering resources.

Automated Test Equipment (ATE) systems serve the critical purpose of ensuring that electronic devices operate according to specifications in the field. The aerospace and defense sectors make substantial investments in ATE due to the criticality of lifesaving electronics utilized in military equipment such as aircraft, naval vessels, and ground vehicles, as well as in various systems like weapons, radar, and wireless communication.

Automated Test Systems (ATS) are widely utilized for testing automotive electronics, batteries, and electronic drive systems in the EV market. ATEs are also used to optimize the performance of telecom infrastructure, analyze and improve the efficiency of renewable energy systems, and validate consumer electronics.

However, a common misconception is that designing and building ATE systems is a straightforward process, one that merely requires identifying test requirements and assembling the necessary components. In reality, effective test system development demands expertise in test system architecture, component selection, software integration, and regulatory compliance, making in-house development a significant challenge for most organizations.

While some enterprises attempt to develop ATE systems in-house, the complexity and cost often outweigh the benefits, diverting focus from core technological advancements. For some companies there can be advantages to turning to specialized providers that can provide all, or parts, of ATE systems.

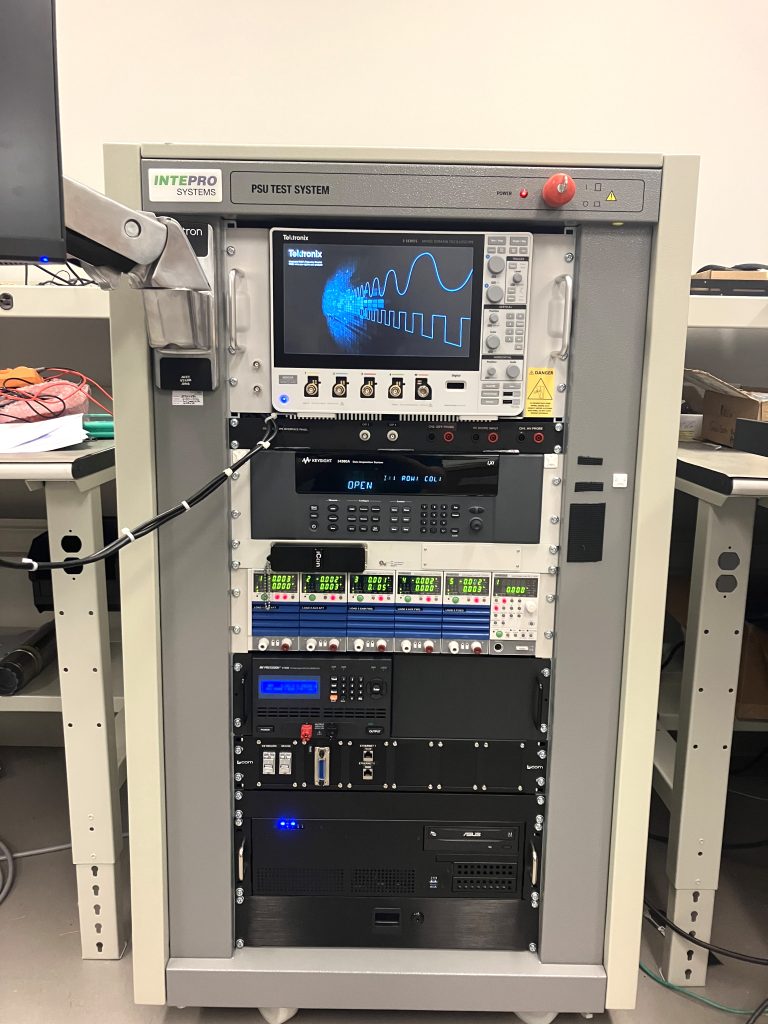

“Many companies are reevaluating in-house design strategies and choosing to outsource all or significant portions of their automated test systems to specialized providers,” says Andrew Engler of Intepro Systems, a supplier of high-power electronic testing systems. “This approach not only ensures access to advanced testing capabilities but also allows internal engineering teams to concentrate on core innovations rather than system validation.”

According to Engler, companies prefer to keep testing and development in-house for various reasons. “For most companies, the first instinct is to allocate internal engineering resources. This approach ensures direct control over the project but introduces inefficiencies,” he says.

Engineers, whose expertise lies in other areas, must take on responsibilities outside their core competencies, requiring them to assemble a solution without in-depth knowledge of testing system design, component sourcing, or software integration. This not only diverts their focus from primary tasks but may also lead to suboptimal solutions and increased project timelines. Intepro creates the documentation including user manual, drawings, and schematics for the system which can be extensive and is extremely time consuming. The company also troubleshoots errors that may arise in the system to avoid having customers pull engineering resources away from their tasks.

In some cases, security and proprietary concerns dictate the decision. Government contracts, for example, may explicitly restrict information sharing, requiring all work to be conducted internally to comply with security protocols. This is common in aerospace, defense, and other industries where confidentiality is critical.

Cost perception is another major factor. Many companies assume that outsourcing is more expensive, reasoning that they are already paying their engineers and should maximize their utilization. However, this overlooks the hidden costs of time spent researching, troubleshooting, and developing automated test systems from scratch—efforts that an experienced external provider could streamline with proven solutions.

“In reality, the cost of a DIY approach can be higher than expected. Engineers are valuable, and their salaries reflect it. When factoring in the hours spent sourcing, vetting, and troubleshooting components, the cost difference between handling it in-house and outsourcing to professional ATE system developers is negligible,” says Engler.

There are numerous custom ATE providers that offer fully integrated automated solutions or, when required, specific hardware and software components to meet unique testing needs.

A typical automated test solution consists of hardware, software, test instruments, signal sources, and test probes or handlers. Software also plays a critical role in test development and management of data collection, storage, reporting, and analysis. These components are usually consolidated into all-in-one test stations, which vary greatly in size and portability, from small, compact test stations on wheels, to large stationary test towers.

Even when manufacturers seek to maintain control over the design of their Automated Test Equipment (ATE), they often turn to a hybrid approach that still involves bringing in outside experts, according to Engler.

“A few of our customers choose to manage their own test stations using internal resources while relying on us for specific components and software. This allows them to maintain control over the design while integrating proven, high-quality elements into their systems,” says Engler.

A company like Intepro, which specializes in power electronics testing specifically, can offer many of the products used in test stations including AC and DC power sources, AC loads, and other standalone equipment.

Intepro’s test systems use off-the-shelf equipment, so engineers can independently search for and purchase these components. However, the sourcing process can be overwhelming, particularly when faced with an extensive selection. A simple request such as finding a 30-volt, 5-amp power supply can quickly lead to sifting through hundreds of thousands of options.

Companies like Intepro have a list of pre-vetted suppliers, eliminating guesswork in selecting reliable components and reducing sourcing time.

Beyond technical specifications, sourcing requirements adds another layer of complexity, particularly in industries like aerospace. The county of origin of a component matters, and while sourcing from overseas suppliers is not an automatic disqualifier, it does raise additional considerations. Security concerns, compliance regulations, and supplier reliability must all be evaluated before making a selection. This requires an additional vetting process to ensure components meet both performance and regulatory standards.

Even the software can be purchased as a standalone product if needed. Every system requires test program software, which plays a critical role in test development and the management of data collection, storage, reporting, and analysis.

“If they prefer to handle hardware selection and system development internally, we can simply provide the software and train the customer how to use it.”

Intepro’s offering, called PowerStar, provides simplified drag-and-drop test routines designed to dramatically reduce development of test programs, from single instrument functional control to full test procedures with easy-to-use parameter entries. Engineers can customize their programs without having to write code or assemble graphical components.

The software solution allows for modifications when project requirements shift – as they often do. Over time, the system’s hardware components deteriorate or become outdated. Alterations in test project and change of scope parameters ensue. Government contracts may not be renewed or could be entirely terminated. Test specifications undergo modifications, sometimes necessitating a complete reconfiguration of the test. Faced with these types of challenges, a more easily adaptable software like PowerStar eliminates the need to rewrite entire programs from scratch. This can significantly reduce timelines and decrease costs.

While designing an Automated Test Equipment (ATE) system in-house is technically feasible, the process is complex, costly, and time intensive. Experienced ATE providers offer the necessary expertise, enabling companies to bypass the steep learning curve, accelerate development, and optimize resource allocation.

Partnering with a skilled integrator with multi-disciplinary expertise and leveraging fully vetted components and software streamlines development, enhances reliability, and allows engineers to focus on innovation while maintaining cost efficiency.