Overcoming Torsion: Cables that Can Withstand Any Twist

March 3, 2025

Torsion is a particular type of load for cables and wires that requires cables to possess special characteristics. Otherwise, users could be faced with damaged cables and operational disruptions. This article will show you what effects torsion can have on electrical connections and what to pay attention to when selecting torsion-resistant cables.

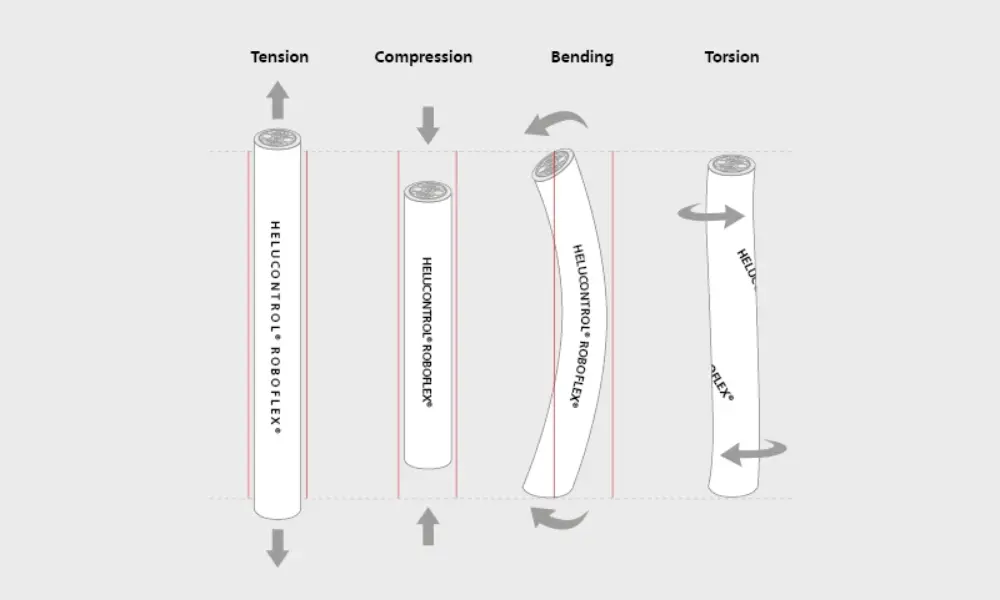

What is torsion?

Torsion is a mechanical load that occurs when an object is twisted along its own axis. With cables and wires, this can occur through repeated movements or rotating components. Applications with torsional loads are most commonly found in robotics, mechanical engineering, and in wind power systems.

Effects of torsion on cables and wires

The regular twisting of cables over time can lead to material wearing out, conductor breakage, or a complete loss of function. Cables and wires that are not designed for applications with torsional loads can suffer the following types of damage:

- Tears: Through perpetual loads, the jacket material can become brittle and develop tears.

- Conductor breakage: Electrical conductors can break due to mechanical strain, which leads to disruptions in the transmission of power and data.

- Shielding issues: Torsion can damage the shielding of cables, which impairs their electromagnetic compatibility (EMC).

- Reduced lifespan: Perpetual torsional loads can significantly reduce the lifespan of a cable.

The solution? Torsion-resistant cables and wires

The HELUKABEL portfolio contains a number of cables that are specifically designed for applications with torsional loads. To make cables and wires torsion-resistant, they must possess certain characteristics:

- Flexible construction: Torsion-resistant cables are made of highly flexible materials that allow for high elasticity.

- Appropriate jacket materials: An elastic and tear-resistant jacket prevents material wear and tears.

- Finely stranded conductors: The use of thin, individual wires makes the conductor more bendable and resistant to torsion.

- Optimal stranding: The conductors within the cable are arranged in a way that torsional forces are equally distributed.

Put to the Ultimate Test

As part of the development process, HELUKABEL tests its cables and wires extensively in its testing laboratories. The company even tests for torsional loads. Through this, it can ensure that every one of its products reliably fulfills the most stringent requirements for daily practical use. Learn more about these torsion tests here .

Torsion-resistant cables and wires from HELUKABEL

HELUKABEL’s product portfolio contains a number of cables for torsion applications. For example, the ROBOFLEX series contains cables that are designed specifically for the extreme mechanical loads of modern robotics and are especially resistant to torsion. They are available in different variations and diameters in the HELUKABEL Online Shop.