First Mate Last Break: Electrical Safety and Reliability for Medical Devices

June 7, 2024

By Martin Wimmers, Managing Director, Fischer Connectors GmbH

Medical device manufacturers must maintain the highest safety standards while ensuring ease of use. Although medical devices are usually enclosed and have easily accessible switches, buttons, and displays, the infrastructure can pose safety risks. Connectors and their connection points are particularly vulnerable, especially when dealing with electricity. It’s important to exercise caution to protect both users and patients, as well as the delicate technology within the device.

The IEC 60601-1 standard for medical electrical equipment provides a clear framework for this. Special “First Mate Last Break” connectors meet the requirements of this standard, offering a combination of electrical safety, mechanical reliability, and user-friendliness.

First Mate Last Break

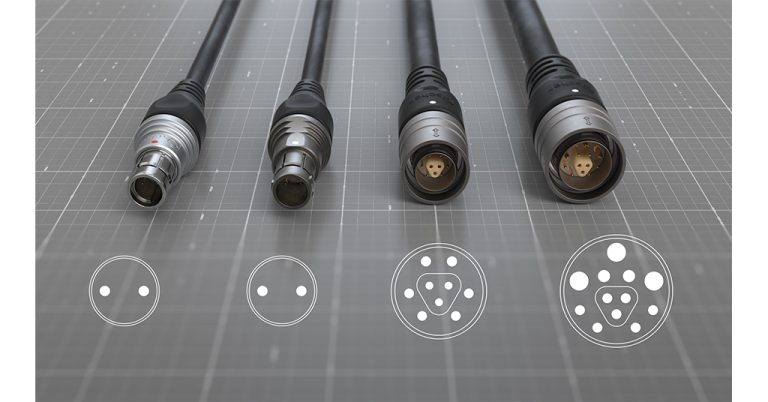

The term “First Mate Last Break” (FMLB) refers to an innovative connector mechanism. In this configuration, the longer contact in the connector is first mated and last broken. This setup ensures that the electrical system is continuously grounded, preventing unpredictable floating signals that can disrupt signal integrity and lead to issues like crosstalk, capacitive coupling, and EMI problems. Without this continuous grounding, there can be risky electrical safety conditions. The First Mate Last Break technology prevents these problems and ensures reliable protection against electrostatic discharge (ESD). It also ensures that any stray voltage is safely directed to the ground, preventing damage to the operator and voltage-sensitive devices.

In medical technology, hybrid connectors are commonly used to transmit data, signals, power, liquids, and gases. Depending on the configuration, these connectors can combine data, power, gas, and liquid transfer in a single high-density connector. This not only saves space but also helps reduce the size and overall weight of medical devices. Additionally, combining multiple connections into a single connector greatly simplifies the plugging process. In emergency situations, such as rescue operations or in intensive care units, every second counts. Therefore, it is crucial to minimize the risk of misconnection through easy plugging and appropriate coding.

A crucial factor for the safe operation of medical devices is the secure locking of connections. Different locking systems such as Push-Pull, Tamperproof, Quick-Release, and Friction Fit are used depending on the application. First Mate Last Break configurations can be implemented in all common locking systems, making it easier for designers to meet different application scenarios and user needs.

The same device may use two different types of locking mechanisms, depending on whether a connector is used for connecting a handpiece or a control console, but all must be safe. First Mate Last Break has no impact on robustness. Like all other medical connectors, First Mate Last Break connectors are sealed to IP68, withstand autoclave sterilization, and resist corrosion (1,000 hours salt spray, 5% salt solution, 35°C). The connectors are particularly durable, withstanding 10,000 mating cycles.

https://fischerconnectors.com/en/news-blog/first-mate-last-break