Smart Flow Control for Fandis Roof Exhaust Units: Comparison With the Traditional System

May 6, 2024

How does smart flow control work on roof exhaust units if compared to a traditional system?

Fandis has recently introduced a new temperature regulation system on it’s roof exhaust units, based on Fandis IoT device, called Sensis. Below the system in question will be compared with a traditional solution, using a concrete application example, created in Fandis laboratories, where the applications of our customers are replicated and simulated.

Laboratory test and comparison with a traditional system

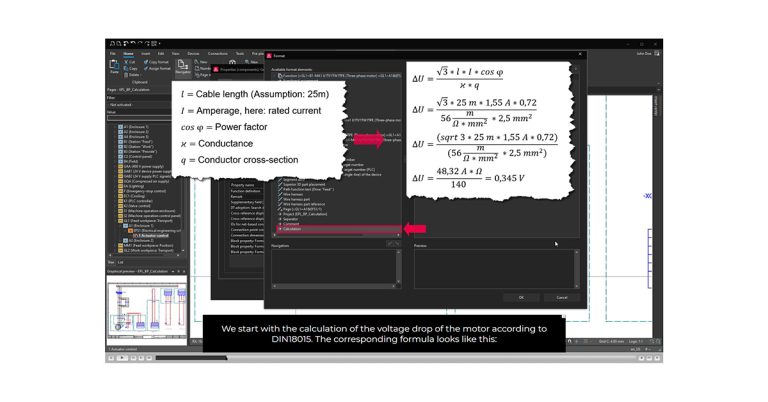

Fandis uses the thermotechnical calculation software (available for free on the Fandis website) and calculate the volumetric flow rate required for a typical cabinet that needs the application of our roof exhaust units: an enclosure made of 0.06in painted sheet metal, measuring 24x24x71in with production of internal heat of about 800W.

Considering installing the cabinet in a covered environment, with a maximum room temperature of 86°F, and regulating the internal one to a maximum value of 95°F, the necessary volumetric flow rate, for the most extreme conditions, will be around 265CFM.

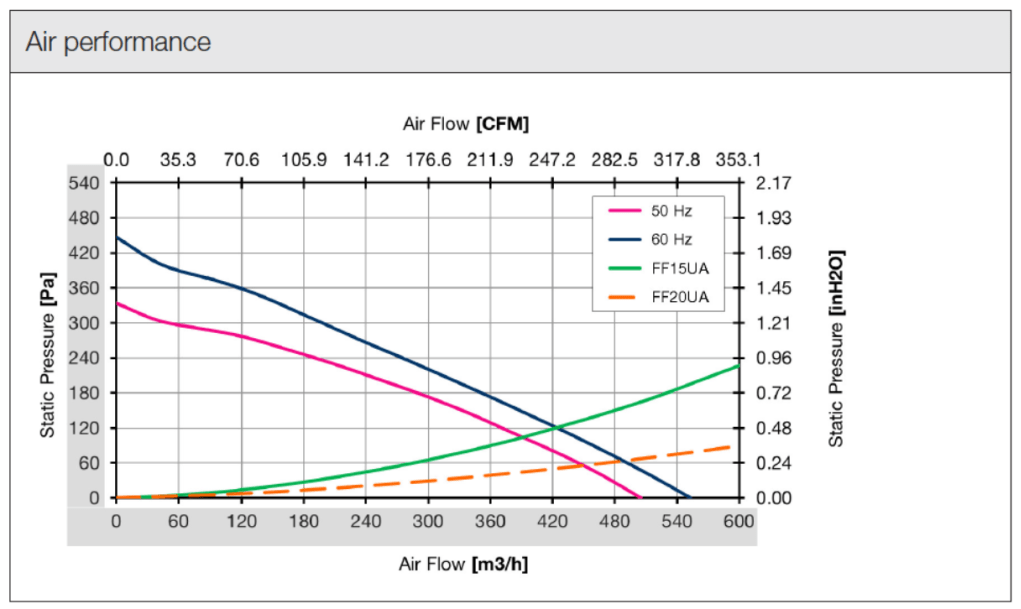

The traditional solution involves a TP19U230B coupled to an FF20A input filter, with an operating point coinciding with our goal and with an absorption of 69W at 50Hz.

By installing the DC fan (TP19UD24) and with the same inlet filter, Fandis can reach, at maximum rotation speed, a maximum flow rate at the working point of 324CFM, approximately 22% higher, but with a power absorption equal to 95W.

However, keep in mind that, since it is a modulating system, it will never work at maximum speeds and that the highest working point calculated for the application is 265CFM.

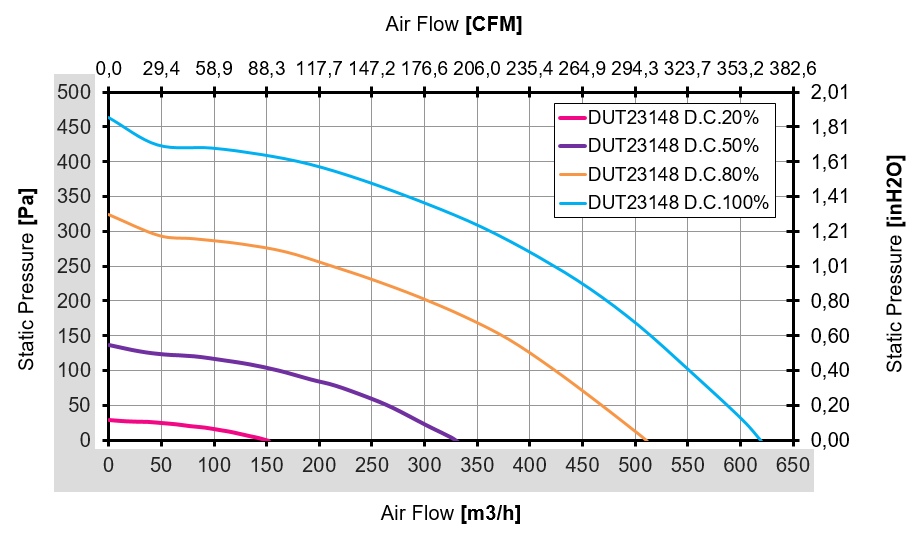

In the following graph is the family of flow rate/absorbed power curves of Fandis’ classic roof fan TP19UD230B. If you pay attention to the maximum working point, calculated for the application at 265CFM, the new system controlled by Sensis stabilizes at a rotation speed of around 80% with an absorption of only 59W.

The advantage in terms of energy efficiency

The real advantage in energy terms therefore derives from the scalability of the power according to the real instantaneous need. To take this further, the working point of 265CFM was determined to satisfy the most extreme conditions, with an ambient temperature of 86°F. If it is assumed that for most of the system’s operating time, the real ambient temperature almost never realistically goes above 77°F, the instantaneous volumetric flow rate will remain around 118CFM, with absorption falling below 20W.

With the traditional solution, one can only act through a thermostat, accepting an oscillatory behaviour of the temperature and a higher degree of noise at maximum speeds. With the technique based on the integration of Sensis and direct current roof extraction towers TP19UD24xx and TP19UD48xx, instead, there is consumption for heat dissipation proportional to the real requirement and a more silent system.

This is yet another example of how Fandis’ new algorithm allows numerous advantages and greater efficiency in the thermal management of an electrical panel.