How Choosing the Right Industrial Enclosure Can Mean Big Things for Material Handlers

March 8, 2024

The rapid growth in e-commerce and a continued skilled labor shortage are two of the hottest topics for today’s material handlers, particularly when it comes to maximizing growth opportunities and securing a larger market share in the material handling space.

The sheer volume of parcels in the pipeline means material handlers need smarter, more powerful conveyor and sorting systems, and, as a result, this means identifying more versatile industrial enclosures that offer a wider range of panel and cable configurations. However, this is complicated by the move to optimize the use of warehouse space via a smaller automation footprint.

This is where the right industrial enclosures that prioritize configuration flexibility and increased cable and panel density can help material handlers optimize their automation infrastructure, regardless of whether production takes place inside or outside the warehouse.

The right industrial enclosure can support retrofitting existing facilities for warehouse automation

The need to increase speed-to-market and accelerate delivery times is key for material handlers, especially as this industry becomes increasingly competitive. Retrofitting existing facilities for warehouse automation has become an extremely valuable path for bringing new distribution centers online, and the right enclosures can help support the retrofitting process and seamlessly integrate into existing automation systems based on demand.

What does the right enclosure for retrofitting for warehouse automation look like? Enclosures designed and engineered for Industry 4.0 and IIoT allow for greater degrees of customization based on unique deployment specifications, and these enclosures also streamline the installation and modification process to help save time and money.

For example, Rittal’s AX enclosure provides simplified, versatile internal configuration for wiring via

● A variety of mounting capabilities without the need for tooling or machining

● Larger gland plates for more flexible cable entry and wiring

● Easy door and hinge assembly reversal, even with double-door enclosures

What’s more, the AX enclosure doesn’t prioritize versatility over protection and durability. Available in carbon steel, stainless steel and fiberglass reinforced polyester, the AX can be deployed in both indoor and outdoor environments with IP 66 and NEMA Type 4X/4/3R/12/1 protection for superior durability and reliability.

The right industrial enclosures are easily scalable to meet demand

The ability to scale parcel processing based on demand is just part of the modern material handling space. Material handlers need the kind of automation flexibility that allows them to ramp up production quickly based on any number of market forces or factors. The right industrial enclosures can help material handlers quickly scale their automation systems without disrupting production or prolonged lead times.

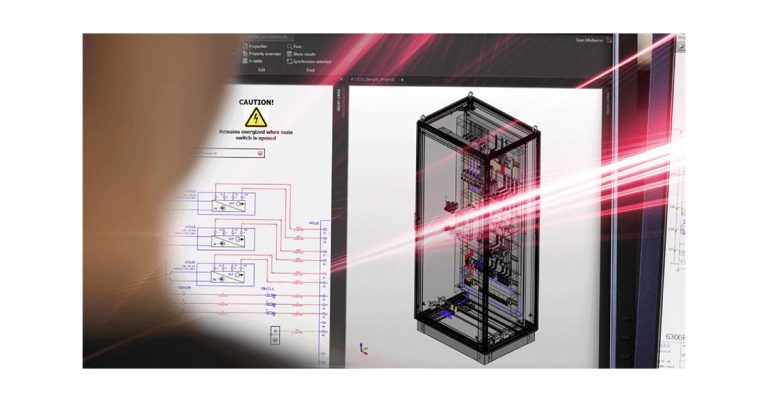

This ability to scale based on demand starts with an end-to-end digitalization of the enclosure design process for real-time insights and visibility into everything from material sourcing to the creation and alteration of panel and enclosure schematics. This approach also creates a more connected ecosystem that allows for real-time schematic changes that enable downstream alterations to enclosure configuration with costly errors or downtime.

Rittal’s line of wallmounted enclosures — in particular the AX enclosures and new WMV Enclosure Type 3R — can be configured and modified in the Eplan suite of Cloud-based design software for a fast, error-free design process that significantly reduces the need for manual intervention.

Digital twins and 3D control panel visualization provide panel builders and installers with streamlined workflows for installing power distribution panels and wiring. Plus, the tool-free nature of panel mounting further simplifies the process of scaling the internal components of the enclosure based on production demands.

What’s more, Rittals enclosures can be quickly and accurately modified at the Rittal Application Center in Houston, Texas using its Rittal Automation Systems (RAS) suite of tools.

The capacity for rapid troubleshooting, maintenance, or in field configuration also impacts how well-equipped an enclosure is to scale based on demand.

Rittal’s emphasis on minimizing production downtime and disruption means its AX enclosures can easily be accessed from the bottom for easy cable and wiring management, and system expansion can be easily done adding rails to the door, or on the side of the AX enclosure, even for dynamic loads.

With the right industrial enclosures, today’s material handlers can bring new facilities online faster via retrofitting facilities for warehouse automation, and they can create more scalable, adaptable automation systems. Rittal can support material handlers in both of these mission-critical tasks.