Is Your Electrical Design Process Tailored Around Your Customer?

July 11, 2023

By David Ridgell, Application Engineer, EPLAN USA

All electrical designs start with an initial assessment of your customer’s desired outcomes. How do you, the panel builder, and your customer both agree that what they asked you to design is what you are going to produce for them?

Designing in 3D

When your engineers work without tightly defined specifications, they can produce designs that are essentially workarounds, rather than optimized systems. This costs you time and money.

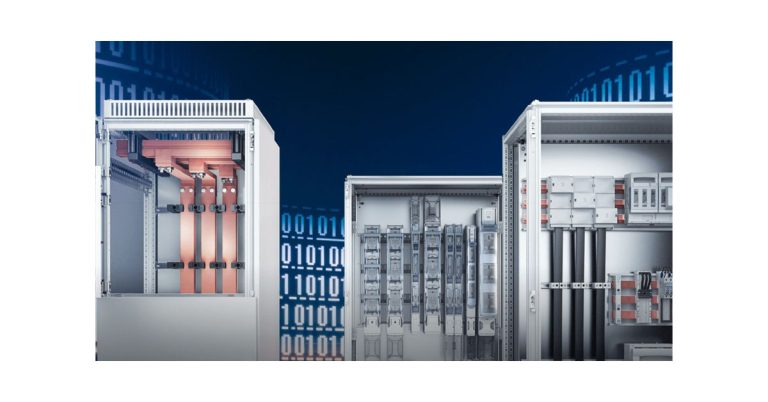

Prior to production, it is important for the engineer and customer to accurately visualize the final product. The best way to do this is through 3D rendering, which gives a better understanding than 2D drawings.

When starting a project, plan your mounting layouts in 3D to help ensure that your components fit comfortably within the allocated enclosure size. If not, components can easily be dragged and dropped into another location, or you can easily and quickly change the enclosure size within the platform.

In addition, some Electrical Computer-Aided Design (ECAD) solutions, such as EPLAN, not only give visual cues for collision control between components, but also identify important airflow gaps. This enables the completed panel to last longer and enables optimum wire routes to make the most of your materials.

The design can still be easily changed to satisfy your customer without high costs, all before going into production – something which cannot be defined by 2D schematic drawings.

Collaborating to Reduce Errors

Some ECAD software providers, such as EPLAN, provide built-in tools or additional applications that enable multiple users to collaborate your projects from different locations, usually via the cloud. Your company can share drawings with your customers and obtain direct markup information imported back to the project file, along with change/comment status tracking. This helps reduce any costs associated with travel, removes the need for back-and-forth emails and helps ensure all stakeholders are working from the same project version.

In addition, the EPLAN platform and the augmented reality (AR) module enables your customers to project the 3D design into their physical environment, helping to ensure the enclosure fits within the allocated space.

Overall, these solutions can help improve your customer’s experience by using these tools to communicate changes quickly and effectively.

Preparing for Manufacturing

The 3D design makes it easy for your customers to share with their internal stakeholders what the final product will look like. This also allows for an understanding between you and the customers of what work needs to be undertaken by different engineers, supply partners and builders working on the panel.

The EPLAN software can automatically generate many reports to help you build the agreed upon panel efficiently and with fewer errors. For example, a wire list report organizes wire by similar colors and gauges. This way, you – the panel builder – do not have to navigate the schematics but can now wire the control cabinet from a wire list instead of using the schematics. These reports play a key part in ensuring that your designs are accurate and correct the first-time, providing your customers the highest satisfaction.

By tailoring the end-to-end design process around the customer, with feedback and evaluation at each stage, you are ensuring that the design is fit for purpose. If you’re ready to take your panel shop to the next level, click here to learn more.

https://blog.eplanusa.com/is-your-electrical-design-tailored-around-your-customer?language=all