Control Panel Design and Assembly Steps

October 11, 2023

Chris Kregoski, product engineer for AutomationDirect, wrote an article posted in April 2022 on PanelBuilderUS.com titled Designing and Assembling Control Panels. Here’s a summary, click on the link for the full text.

Modern digitally controlled machines, equipment, and systems incorporate increasing numbers of smart devices and field sensors. Industrial control panels are necessary to support the electrical, instrumentation, and control (EIC) aspects of these systems.

Understanding the basics of designing, assembling, and testing control panels is important for original equipment manufacturers (OEMs) and systems integrators (SIs), and for the end users who will receive these panels and operate them for years or decades. Panel design is a specialty, and it requires much more than picking some parts and bolting them into an enclosure, but there are many products and resources to help get the job done.

Requirements

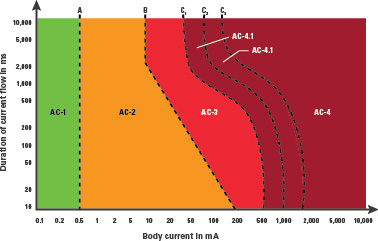

Project needs are defined and specified by some level of requirements. Sometimes these are huge and detailed documents, while other times they are more informal. And all designs must comply with applicable electrical, UL, and safety codes—along with local requirements, and regulations. EIC devices are installed into control panels to:

- Protect them from the environment

- Guard workers from contacting them

- Distributing, converting, and protecting electrical and communications circuits

- Centralizing EIC devices like PLCs, I/O, HMIs, VFDs, networking, instrumentation, and more by installing them in one panel

Drawings

Design personnel need to consider power consumption, overcurrent protection and conductor sizing, conductor/cable tagging and routing, UL requirements, and code compliance. Drawing packages define the work, and should include some or all of the following:

- Cover page and drawing list

- Bill of materials (BOM)

- Schedule of nameplates and tags

- Cable and/or wire lists

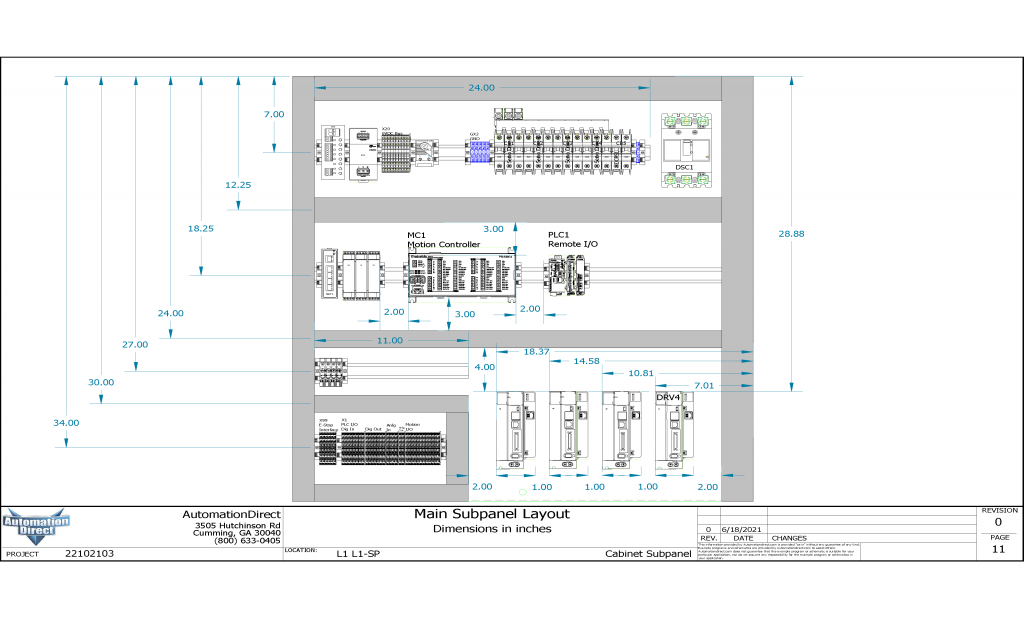

- Interior layouts with dimensions and wire management provisions

- Power distribution and grounding drawings

- Block diagram and/or communication system architecture

- I/O module and field termination strip drawings

- Intelligent device drawings for VFDs, motion controllers, and the like

Details

Products are selected to meet the requirements, and designers must create a layout, size the enclosure, and perform many other design steps in an iterative process. Some key elements of this work include:

- Enclosures: Choosing materials suitable for the environment and sizing them.

- Layouts: Designed for easy assembly and future expansion, segregating cables as needed, and incorporating HMI devices and other components as required.

- Thermal management: Devices generate heat and have minimum and maximum operating temperatures, so heaters, air conditioners, and/or fans may be needed.

- Schematics: There are a variety of schematic styles and numbering/labelling methods. Designers can start the schematics early in the process, but they can only be finalized once all the device makes/models are chosen.

Assembly and Testing

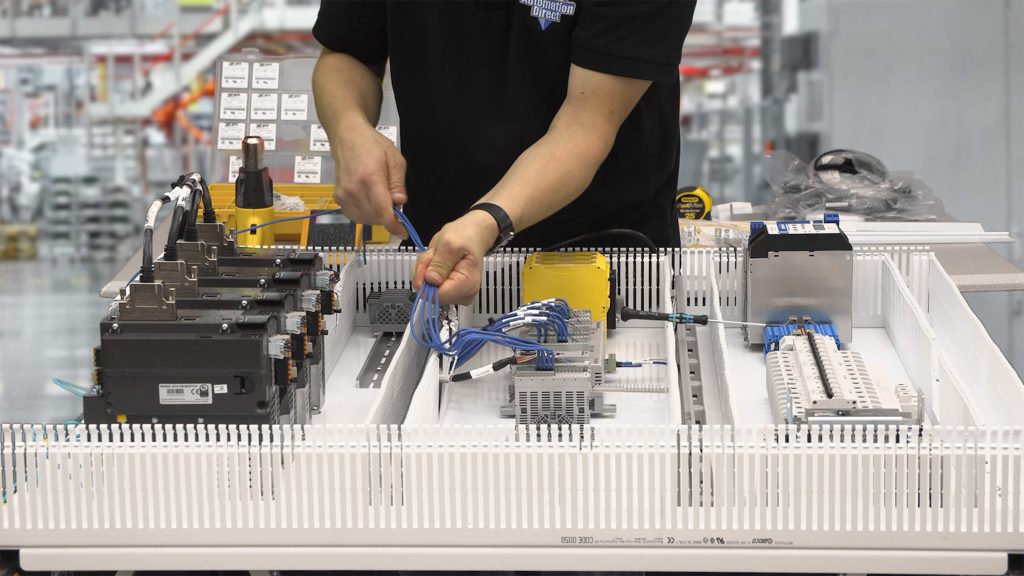

Careful and workmanlike assembly will pay off during the building phase, and it will improve the appearance and professionalism of the control panel. The interior backplane must be marked and drilled, and then DIN rail and devices can be installed. Wiring and grounding are the next steps.

A good testing program will verify parts, check ratings, inspect the layout/arrangement/tagging, and confirm the wiring and grounding. Eventually power will be applied, and some functionality tested.

Build on the Basics

AutomationDirect is ready to help OEMs, SIs, and end users everywhere with all their panel building needs. The AutomationDirect website offers an extensive portfolio of enclosures, EIC components, PLCs, HMIs, VFDs, accessories, and much more, along with design tools and helpful online/phone support.