How Busbar Power Distribution Can Help Manufacturers Maximize the Space Inside Their Industrial Enclosures

November 3, 2023

One of the more pressing concerns for automation architects in the last year is specifying equipment that can help manufacturers reduce the footprint of their industrial automation infrastructure.

This is particularly important for manufacturers who are looking to retrofit existing facilities for warehouse automation, as older buildings often come with unique floor plans or space constraints.

The other ongoing challenge is how control manufacturers and panel builders can optimize the space and configuration inside their industrial enclosures. Recently, this conversation has centered on integrating busbar power distribution panels, which, compared to more legacy wiring systems, allow for greater wiring flexibility.

Busbar power also has the capacity to help manufacturers unlock more efficient energy consumption, which is key for several industries, particularly for automotive and energy & power companies.

With this in mind, let’s look at a couple of key ways busbar power distribution can help manufacturers maximize the space inside their industrial enclosures, and reduce their energy usage to create a more eco-friendly automation system.

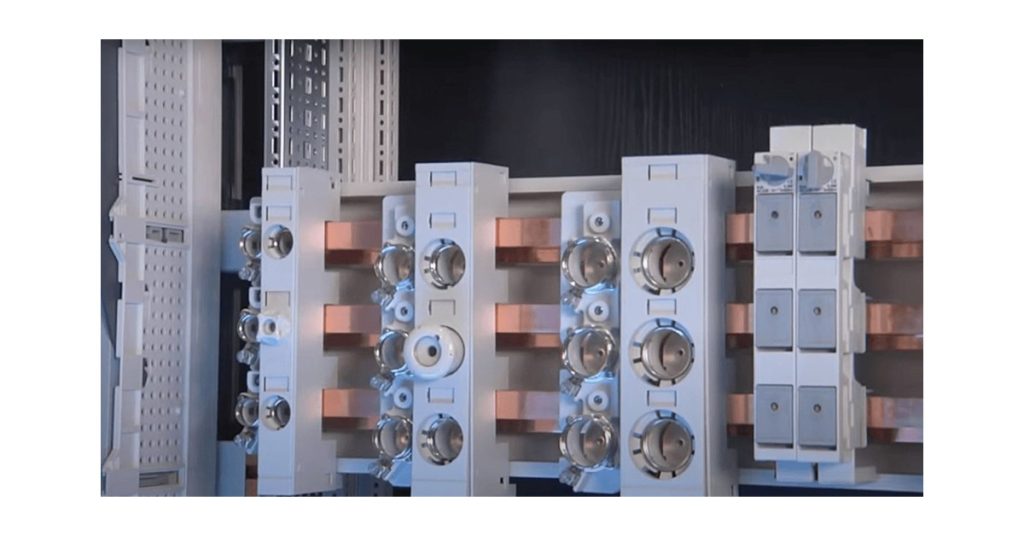

Busbar power panels are smaller and don’t require large power blocks

One of the biggest value-adds busbar power offers in helping control designers optimize the use of space inside the enclosure is that they use smaller, more versatile components, and they also eliminate the need for large power blocks that are common with more traditional panel wiring.

Busbar power panels are designed to replace the side line wiring and accessories of an industrial electrical panel. Legacy industrial panels use large quantities of wires and cables to connect to power distribution blocks (PDBs), which are bulky and take up large amounts of space inside the enclosure. Typically, the larger the enclosure, the more PDBs are required in order to adequately power the controls inside.

Additionally, legacy wiring systems can require multiple feed cables to sufficiently energize the panel. Busbar power panels can replace these cables via a single conductor that carries the same amperage while freeing up space inside the enclosure. Plus, this streamlined design gives designers more freedom and control over how busbar power panels can be installed.

For example, Rittal’s Mini-PLS Busbar System utilizes a 3-pole, plug-and-lock connection at the front of the panel for easier, more efficient cable configuration. Plus, the Mini-PLS Busbar System offers a variety of mounting capabilities, including a top-mounting that allows for a more versatile use of space inside the enclosure.

From an assembly and installation perspective, busbar’s reduced size and configuration versatility make it easier for panels to be swapped, and this also helps accelerate maintenance and troubleshooting. Busbar panels do not require as much specialized tooling as traditional wiring systems, which also helps maximize uptime and productivity.

Busbar power panels utilize a simplified design for easy configuration

Modular busbar power distribution panels use a variety of pre-engineered components designed to make connections with a wide range of copper conductors. Panels can be configured in varying sizes and lengths based on unique or custom specifications, which helps optimize the panel footprint for any given application.

In addition, busbar power panels are manufactured using a series of International Electrotechnical Commission (IEC) guidelines that establish a standardized design that simplifies the dimensions and specifications of busbar power distribution. Compared with the more variable nature of traditional panel wiring, the standardization of busbar power allows design engineers and panel builders to configure panel layouts across a wider range of enclosure configurations.

Modular busbar panels further optimize panel wiring and configuration efficiency via the ability to scale based on demand. With traditional control panels, the sizes and configurations of wires are restrictive and there is very limited room for expansion or alterations — and, if alterations can be made, drilling or tapping of the enclosure is often required. However, a modular busbar power system can be modified to accommodate different configurations or expansions without the need for drilling.

Busbar power systems can also be easily retrofitted and customized to accommodate a variety of unique wiring configurations that are necessary for unique enclosure deployment.

For the automotive industry, this capability makes busbar power especially valuable given the race to build a national network of electric vehicle charging stations, many of which must be able to operate in uncontrolled or unconventional environments. The same principle applies to the power & energy sector with the continued growth of alternative energy sources like wind, solar, and water power.