Why Busbar Power is the Ideal Power Distribution System for Energy & Power Applications

February 10, 2025

By Moises Abreu, Business Development Manager, Rittal

The biggest priorities for designing power generation and storage facilities are scalability and flexibility. The rapid increase in the number of electric vehicle (EV) charging stations and solar and wind power facilities demonstrates the need for flexible automation solutions that can be scaled to meet demand without compromising productivity.

Whereas more traditional block-and-cable power distribution solutions create some significant roadblocks in terms of accelerated configuration to meet increases in demand, busbar power distribution combines superior configuration and deployment flexibility with the ability to handle the kind of elevated amperage loads today’s energy & power applications require.

Here are a couple of reasons why busbar power distribution systems are ideal for energy & power applications, and how choosing busbar can help increase productivity and process efficiency.

Busbar is better equipped to handle higher amperages

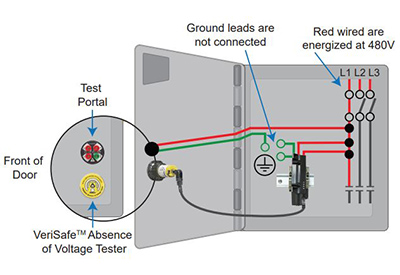

For power generation and storage applications that require more than 800A, copper busbar power panels can facilitate consistent, reliable power distribution without the fear of failure or breakdown. The heat generated by such elevated amperages can melt the cables used in traditional block-and-cable power equipment, thus increasing the likelihood of larger, more widespread equipment failures.

Such safety concerns are a big component of UL 891, a recent global switchgear safety update that requires low-voltage switchgear applications to use low flammability equipment to help reduce fire hazards. UL 891 also stipulates equipment that is resistant to heat and moisture, both of which are detrimental to block-and-cable power distribution systems.

Busbar power panels can facilitate both low- and high-voltage power distribution models in accordance with UL 891 and with an emphasis on long-term consistency and reliability to help increase the lifespan of equipment and maximize ROI.

Busbar power panels provide increased configuration and modification flexibility

The ability to create a custom power distribution infrastructure using standard components is essential for power generation and storage applications — this helps accelerate speed-to-market and simplifies the task of adapting to design alterations in the case of space constraints.

Busbar power panels can be manufactured to a variety of widths and lengths based on the configuration constraints and the amount of power required to electrify the enclosure. Busbar power distribution also removes both the bulky PDUs and the line-side wiring and cable management necessary to electrify enclosures.

This enhanced level of flexibility and versatility also makes busbar a more scalable power distribution model. PDUs can require modifications like drilling or cutting to accommodate scaling a system to meet demand, but busbar power can be scaled quickly and simply, often with nothing more than screws, clamps, and connectors.

For larger-scale modifications, busbar is also a time-saving power distribution solution, especially when partnering with an automation expert that has the machinery to automate modifications like busbar cutting, drilling, and bending.

Copper busbar modification equipment is a key component of the Rittal Automation Systems (RAS) suite to help leverage custom busbar solutions for almost any power generation and storage application.

Busbar power helps increase efficiency and productivity

Copper busbar is a bread-and-butter power distribution solution for power generation and storage applications because of its highly conductive nature and ability to carry low- and high-voltage loads reliably and efficiently. The conductive makeup of copper busbar makes it ideal for applications like EV charging stations, which require the capability to conduct high currents between batteries and charging terminals.

The same benefit holds true for large-scale power generation and automation systems, particularly those of 800A and higher. In these industrial applications, the ability to distribute low- and high-voltage electrical currents is essential to consistently and efficiently power equipment, and busbar can help manufacturers create a more efficient and centralized power distribution model.

Plus, the ability to accommodate more busbar panels into a single enclosure and reduce the amount of enclosures required to power drive systems can help centralize and consolidate power distribution infrastructure.