Which Modular Suspension Arm Is Best for Your Industrial Electronics?

June 19, 2023

CONFIGURE YOUR PERFECT SUSPENSION ARM

Advanced modular suspension arms have made it easier than ever to specify customized supports for your displays, HMI enclosures and panel PCs. By combining profiles, elbows, joints and bases, you can configure your ideal suspension arm very easily.

But despite this simplicity, there are still important factors to consider when specifying your perfect suspension arm. They include:

- Load capacity – will the arm support the weight, even at maximum extension? Longer arms (1 metre +) reduce load capacity. And so do multiple joints or certain types of bases (intermediate joints -40%, base -25%).

- Range of motion – does the arm allow easy adjustment of the HMI panel enclosure’s position to accommodate different viewing angles and user preferences? Does it provide sufficient flexibility and stability to maintain the desired position?

- Robustness and durability – will the arm withstand the demands of your specific industrial environment? A good aluminum or steel arm should feature high-quality components that can endure frequent adjustments and vibrations.

- Ergonomics – does the arm offer easy height and tilt adjustments to optimize the viewing and operation for the operator? Follow ergonomic guidelines and standards to promote user well-being and ensure greater productivity.

- Mounting – the arm should offer suitable mounting options for the specific device and application. Check the VESA mount compatibility of the display, HMI enclosure or panel PC. Ensure that the suspension arm supports the corresponding VESA standard, such as VESA MIS-D.

- Compatibility – verify that the arm is compatible with the device and its required connectors, cables and accessories. Do the profiles have sufficient capacity to accommodate and manage power and data cables, integrated USB ports or additional peripherals?

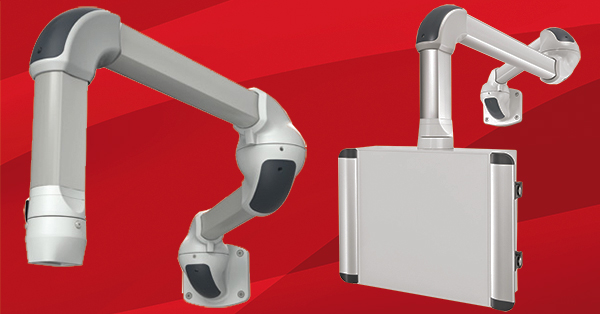

New TARASMART SUSPENSION ARMS

Tough, stylish taraSMART (IP 54) supports light-to-medium loads – displays, panel PCs and HMI enclosures weighing up to 45 kg. This ergonomic new model benefits from many of the advanced technical features of the profiPLUS 50 and profiPLUS 70 ranges but offers them at a very attractive price point.

Applications include smart factory and process automation, modern machine control systems, robotics, medical/laboratory technology and information stations. Like other ROLEC support arms, taraSMART is configured by combining extruded profiles with diecast joints, elbows and couplings.

But unlike some of the other ranges, you can specify either round (Ø 48 mm) or rectangular (40 x 60 mm) aluminum profiles. At headline level, this offers greater choice – and yet the list of components for taraSMART totals just 22.

In their standard colors, these smart modern arms have silver anodized profiles; the diecast aluminum system components are light gray (RAL 7035) with anthracite gray (RAL 7016) thermoplast covers.

PROVEN TARAPLUS SUSPENSION ARMS

Tried and tested taraPLUS (IP 54) also has round (Ø 48 and 70 mm) and rectangular (40 x 60 mm) profile cross sections. But this time, the arm combines the two profile shapes to provide increased static equilibrium. And there are more (36) joints, profiles and couplings to choose from. Set screws enable rapid adjustment.

Generally, taraPLUS also offers a higher load capacity than taraSMART, though it is still below 60 kg. However, arm length is crucial. Soon after you get beyond 1.5-metre arm lengths, it is taraSMART that supports slightly heavier loads.

All the taraPLUS profiles are manufactured from drawn steel and powder coated in light gray (RAL 7035). System components are diecast aluminum (window gray, RAL 7040).

STRONG, EASY-TO-ADJUST PROFIPLUS 50 SUSPENSION ARMS

Advanced premium profiPLUS 50 (IP 54) is the ideal suspension arm for ROLEC’s multiPANEL and profiPANEL HMI panel enclosures. With patented ‘one screw adjustment’, it is fast and simple to set up these arms so they meet your exact ergonomic requirements.

They offer greater load capacity than both taraSMART and taraPLUS. With a load capacity of 80 kg, profiPLUS is one of ROLEC’s stronger arms. Only profiPLUS 70 and the mighty QUADRO 80 can handle heavier loads.

The extruded aluminum profiles of profiPLUS 50 offer plenty of space for HDMI/DVI cables and network adapters. And there is integrated cable protection for added peace of mind. But it’s when you explore all the different joint/base, elbow and coupling options that profiPLUS 50 really comes into its own…

There are 52 different couplings and elbows alone – and 16 adapters, including ones for VESA mountings, and for Siemens, Beckhoff and B&R screens. There is also a 70/50 adapter which enables profiPLUS 50 to connect to components from the larger-width profiPLUS 70 range of arms.

All the profiPLUS 50 support profiles are finished in anodized silver, with diecast aluminum system parts powder coated in light gray (RAL 7035).

LARGER-CAPACITY PROFIPLUS 70 SUSPENSION ARMS

You won’t be surprised to learn that profiPLUS 70 (IP 54) offers all the technical benefits of profiPLUS 50 – but with a higher load capacity and more space for cables and connectors. Strong profiPLUS 70 arms can handle loads of 120 kg – that’s 40 kg more than profiPLUS 50.

The profiPLUS 70 range features 46 different joints, bases, profiles, adapters, couplings and elbows. That’s not as many as profiPLUS 50, but it’s still plenty of choice. And besides, simple configurations are best for larger arms if you’re to maximize their load-bearing capacity.

The materials, construction and standard color scheme for profiPLUS 70 are the same as for profiPLUS 50. This makes it easy to blend components from the two ranges using the 70/50 adapter from the profiPLUS 50 range.

HEAVY-DUTY QUADRO 80 SUSPENSION ARMS

QUADRO 80 (IP 54) is ROLEC’s biggest and toughest suspension arm by a significant margin. Its 150 kg load capacity is 30 kg more than next-placed profiPLUS 70. All the profiles are 80 mm cross-section (which is how the range got its name).

QUADRO 80’s sophisticated design means it can be assembled quickly at its point of use. All the articulated parts feature a swivel limiter. The choice of system components is smaller than in other ROLEC suspension arm ranges – just 14 joints, sockets, profiles, adapters and couplings – but this simplicity makes it quicker to configure your chosen arm.

All of QUADRO 80’s profile sections are manufactured from drawn steel for added strength, giving the arms an extremely high static equilibrium. They are powder coated in light gray (RAL 7035). Meanwhile, the various joints and other components are diecast from aluminum and spheroidal graphite iron, again to ensure rigidity and robustness. They are powder coated in window gray (RAL 7040).

COMPARE GENERAL LOAD-BEARING CAPACITIES FOR EACH SYSTEM

View the above graph to compare the maximum recommended load for each modular suspension arm system.

Load-bearing capacity is affected by arm configuration. As previously stated, factors include arm length, use of an intermediate joint, and use of a base.

SPECIFY CUSTOMIZED SUSPENSION ARMS

All ROLEC suspension arms can be specified fully customized. At the simplest level this means profile sections manufactured to your preferred length (to within a millimetre). Services also include machining, engraving, laser processing, custom colors, screen/digital printing of legends, logos and graphics, and assembly of the arms.

View the full range of customization options

https://www.rolec-usa.com/en/news/blog/blg2306-compare-suspension-arm-systems