The Benefits of a Connected Ecosystem for More Streamlined Enclosure Assembly and Installation

December 18, 2023

A look at manufacturer challenges, and how connected ecosystems can help ease the burden

A recent survey of 200 global manufacturing decision makers found that the most pressing challenges manufacturers are likely to face in 2024 includes creating more agile and resilient production cycles. This is due in large part to the continued skilled labor shortage, and how increased consumer demand for a variety of goods is forcing manufacturers to figure out how to maintain productivity in the face of a limited labor pool.

As a result, manufacturers are incorporating more advanced automation solutions to help unlock greater levels of productivity and efficiency in the coming year. This enhanced level of visibility and transparency affects more than just the automation designer and engineers who are specifying industrial enclosures, cooling units, or busbar power systems.

In fact, creating a more connected ecosystem can accelerate the enclosure assembly and installation process, and this helps increase your speed to market and makes for more flexible production.

This article will look at a couple of ways a more connected ecosystem helps streamline industrial enclosure and assembly.

A connected ecosystem helps create more precise enclosure modifications

The continued diversification of modern manufacturing means companies need custom industrial enclosure solutions that can be modified to meet any number of unique deployment challenges — for instance, material handlers are relying heavily on retrofitting existing facilities for warehouse automation, and these facilities can provide a host of obstacles in terms of layout and space.

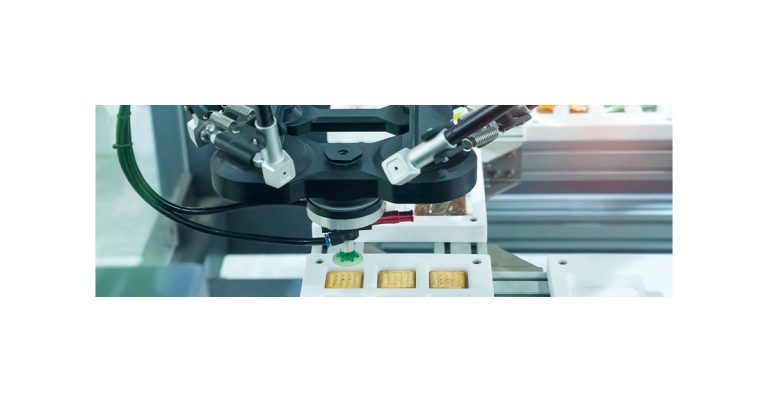

With such unique production parameters comes the need for more sophisticated, precise enclosure modifications that make it easy for assemblers and installers to deploy enclosures quickly. Accurate, high-quality milling, cutting, and drilling are key in modifying panels that can be seamlessly integrated without the need for specialized tooling.

What’s more, increased end-to-end visibility and transparency in the design and configuration phase simplify any troubleshooting of assembly and installation by providing complete, easily accessible digital schematics that offer a digitalized, 360° view of the enclosure.

The Rittal Automation Systems (RAS) suite of enclosure modification, panel processing, and wiring machines can help you increase the speed, precision, and complexity of modification and processing tasks. What’s more, Rittal’s RAS solutions are compatible with powerful design software platforms for rapid design and accelerated downstream assembly and installation.

For example, Rittal’s Perforex Milling Terminal MT S provides reliable machining of mounting plates, doors, roof plates, side panels, gland plates, or unibody enclosures. Ideal for modifying Rittal’s most popular carbon and stainless steel enclosures, the Perforex MT S leverages an intuitive user interface where drawings can be viewed and updated in real time for maximum flexibility and scalability.

While RAS solutions like the Perforex MT S come standard with Rittal software, the Perforex MT S is compatible with Eplan’s powerful CAE software to help digitalize the end-to-end panel modification process via 3D panel modeling, data sharing, and digital twins. This helps increase the flexibility of your modification workflows, and it helps you better understand your current production capacity to scale your operations based on need.

With a more connected ecosystem, assemblers and installers can better adapt to changes in production demands

The ability to scale your automation infrastructure based on production demand or space constraints within a given manufacturing site is fundamental in creating the kind of agile production program manufacturers are expected to need going forward. The capacity to scale an automation system certainly impacts designers and engineers, but it can also affect assemblers and installers, and working toward a more connected ecosystem can simplify the scaling process on the factory floor.

One common task for scaling production is reconfiguring or adjusting the mounting panels inside the industrial enclosure to accommodate more wires and cables. A more connected ecosystem provides assemblers and installers with detailed schematics that can be updated in real time to reflect a variety of variables, like the availability of parts.

What’s more, a more connected ecosystem removes a number of the manual tasks assemblers and installers must execute when processing and readying wires and cables to be installed inside the enclosure. Rittal wire processing machines can be easily used in conjunction with Eplan’s wire processing software to reduce the number of manual interventions it takes to wire a panel, reduce downtime, and increase the precision and accuracy of your wire processing.

For panel wiring and modification on a larger scale, Rittal’s fully automated Wire Terminal WT C enables wires to be processed from bulk with individual wire printing and then readied for assembly. The WT C offers flexible configuration, a quick change system for wires, process reliability, three wire output methods, and a digitally supported process. Additionally, the WT C is adaptable and offers an expandable modular system structure to meet future requirements.

These solutions not only help installers and assemblers better respond to fluctuations in production, but they also equip manufacturers to maximize uptime and prioritize productivity in the face of skilled labor shortages. But this is just the beginning of how a connected ecosystem can help you get to where you need to go.