How Can the Availability of a System Be Increased?

March 1, 2023

By Nadine Schinko, Assistant Marketing & Inside Sales, PULS Power

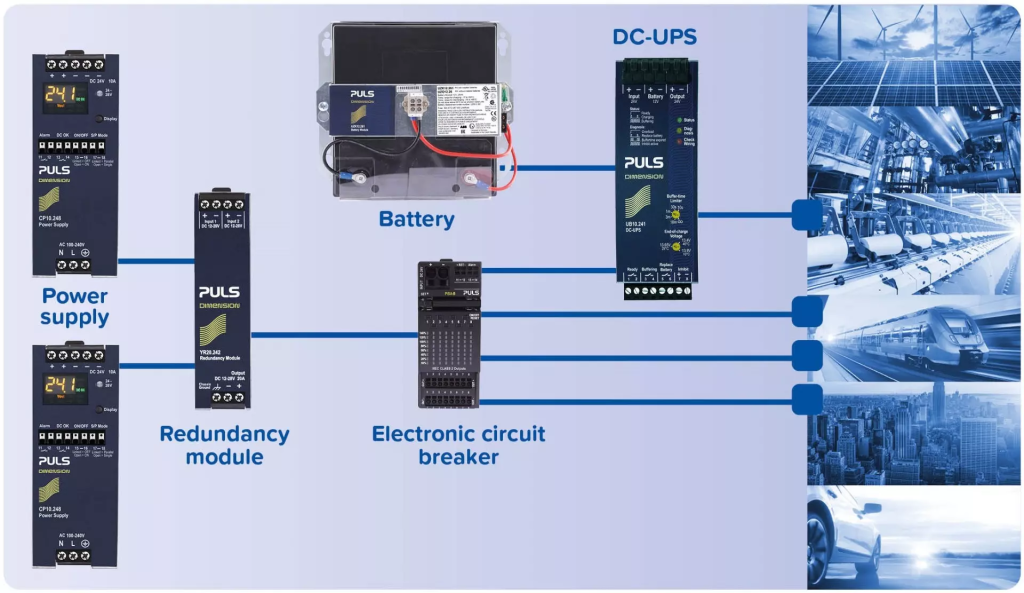

For plant operators, the primary goal is to ensure maximum availability of machines and systems. This requires a reliable power supply throughout the entire lifetime of the system. Therefore, it is important that the applied power supplies are reliable, safe and durable. Within a power supply system, however, the power supply unit is often just one component among many. DC UPS, fuses and redundancy or buffer modules are also included. Such a holistic power supply system must be planned conscientiously. Find out more about what you should pay attention to in the blog article.

With the right system approach in the background, users no longer have to worry about the availability of their system. Ideally, they already deal with feasible solutions in the planning phase so that a system failure cannot occur in the first place.

What does system availability mean?

The system availability indicates the relationship between the planned operating time and the actual operating time. The higher this value, the more efficiently the system operates. The availability of a system or machine therefore has a direct influence on the productivity and effectiveness of the company, which is why it must be ensured under all circumstances.

As a manufacturer of industrial power supplies, PULS focuses on the DC supply, within the application. The power supplies are the interface between the power grid and the internal systems. The quality of the mains voltage is therefore an essential factor in the all-encompassing consideration of a solution. System designers should take this into account as early as the planning phase of a system.

The risk of poor power grid quality

PULS operates three of its own factories in Germany, China and the Czech Republic for the production of its products. System availability is also a top priority here, but is heavily dependent on the local quality of the grid voltage. This is particularly clear from the example of the PULS factory in the Czech Republic. Statistically, Czech companies are affected by 0.6 network failures in average per month. The European average of 0.3 network failures per month is just below this, which sounds very low at first. However, this value indicates that, statistically speaking, a production facility in Europe is affected by a power outage every three months.

In Europe, the stability of the grid voltage is generally very high, which is unfortunately rarely the case in other parts of the world. The power grid in the eastern part of Asia and the Pacific region already fails 4.8 times a month on average. In the USA, too, just under a quarter of the companies surveyed are affected by a power outage at least once a month.

If the mains voltage is of poor quality, it potentially causes damage to production machinery and economic losses. For large manufacturing sites, this quickly means costs in the millions. An important aspect here is also the issue of safety. A system must remain permanently safe in the event of a fault and must not pose any danger to users.

This makes it all the more important to integrate a suitable overall system for a reliable power supply. Appropriate protective measures, which can be realised for example by uninterruptible power supplies (DC-UPS) and battery systems, provide a remedy.

The power supply unit as a component of a power supply system

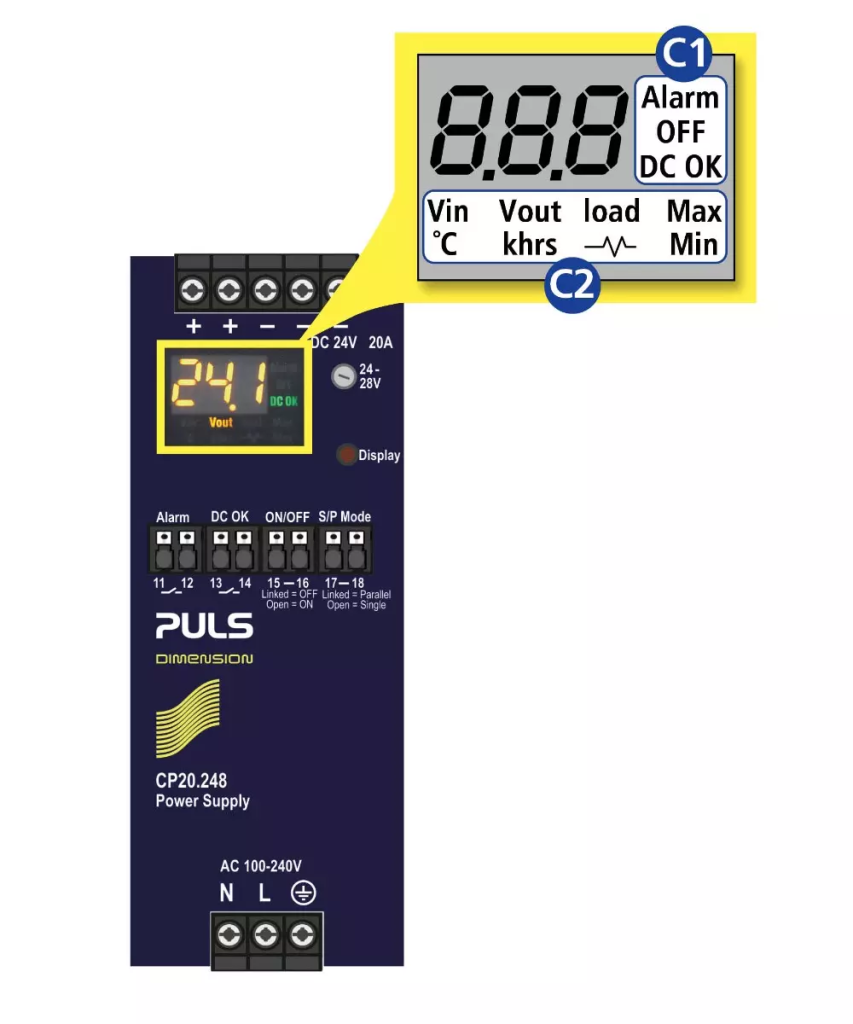

The heart of any application is the power supply unit. For the customer, a CP10.248 was selected in the current example (see graphic). This is a single-phase 24V power supply unit with 10A. The special feature of this variant is the integrated display, via which the user and service technician can keep an eye on all relevant information about the status of the application as well as the quality of the mains voltage.

The power supply has a real-time mode that displays, for example, the current value of the input and output voltage, output current, operating time and the current temperature of the power electronics.

In addition to real-time data, the power supply also provides an overview of recorded data. For example, users can view the minimum and maximum values of input voltage or device temperature at any time (see graphic 2, C2).

The power supply unit also detects transients on the input side and reliably counts them. In the event of a fault, the device triggers an alarm (see graphic 2, C1) and informs the user of the status. Since this enables the situation to be analysed quickly, downtimes can be minimised.

Another means of increasing system availability is the use of a redundant power supply system. Two identical power supplies are connected to a PULS MOSFET redundancy module (e.g. YR20.242 ) for this purpose. By connecting the two power supplies in parallel on the output side,1+1 redundancy is created. This means that in case of failure of one power supply, the full load is immediately transferred to the functioning power supply.

The MOSFET redundancy module decouples the two power supplies in the circuit. Consequently, each power supply unit must be able to handle the load to be applied in the application on its own in the event of a fault. A redundant power supply system increases the availability of the system enormously.

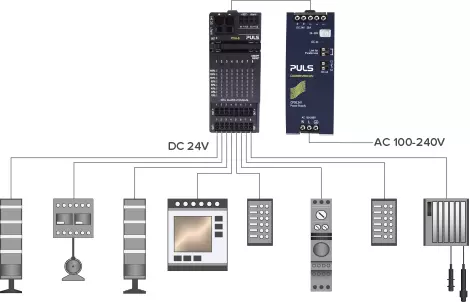

Load protection by electronic circuit breakers

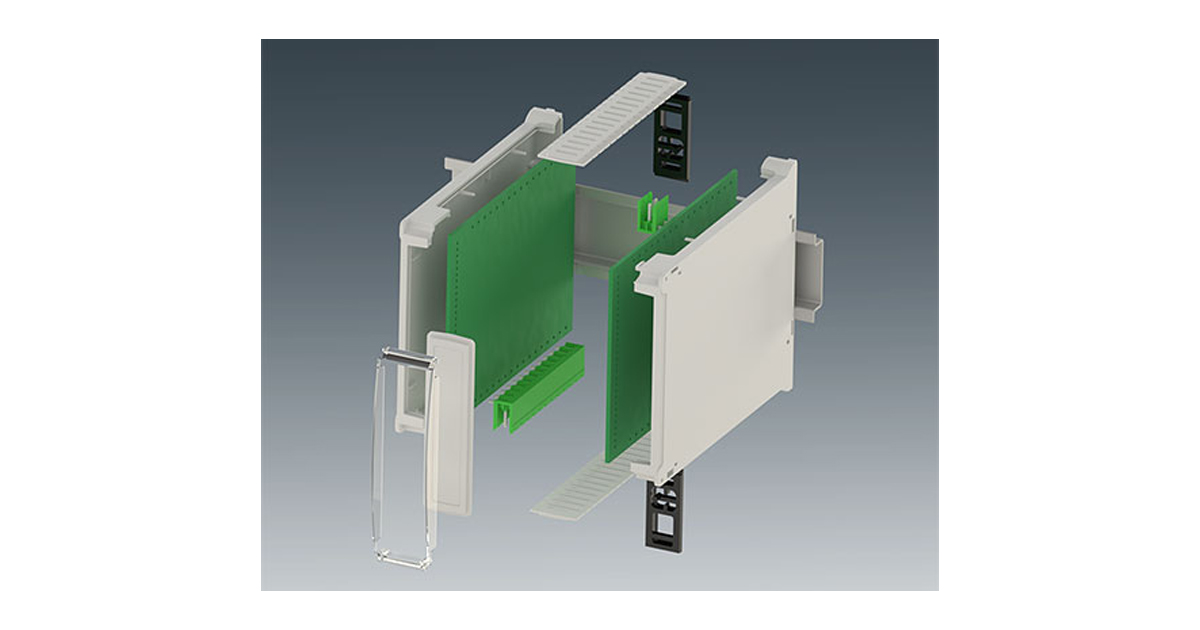

If several different loads are connected to one power supply unit, it makes sense to use an electronic circuit breaker. In the above example, the customer uses an electronic circuit breaker with 8 channels, of the PISA-B type.

The device transfers the current equally to the different channels and allows different tripping characteristics. Channels 1 and 2 are optimised for loads with large capacitances. The output currents and the threshold values for the tripping behavior are displayed individually for each channel via an LED matrix on the front of the device.

The electronic circuit breaker can also be locked with a PIN code to prevent tampering and thus increase safety. If a channel is overloaded, the electronic circuit breaker triggers an alarm and informs the user. In this way, the user always has an overview of the system status, even from a distance. Via a relay input, it is also possible to reactivate switched-off channels remotely. This increases the availability of the system and reduces downtimes.

For safety-critical loads, a DC UPS is recommended

The quality and reliability of the mains voltage plays an important role in the design of a system. An uninterruptible power supply (UPS) is particularly recommended in applications with safety-relevant loads, such as systems for plant safety (e.g. light barriers, emergency stop switches, etc.), emergency lighting or pumps in municipal water treatment.

Mains failures and similar fault situations can be bridged in this way in conjunction with a battery. The buffer time depends on the selected battery size and the load. Depending on requirements, it is suitable for a short or longer buffer time. If the longest possible buffer time is required until a repair is carried out, a larger battery is needed. Small batteries, which have correspondingly shorter buffer times, are sufficient to shut down machines and bring them to a safe state.

Critical loads and applications can be optimally protected depending on the objective and with sufficient local grid quality. In our customer example mentioned above, the DC UPS and the battery are connected between the respective load and the electronic circuit breaker. The customer chose a UB10.241 with the UZK12.261 a lead-acid battery module with 25Ah, for the mentioned device combination. With an already aged battery and 10A load, this results in a buffer time of at least 40 minutes. In the existing example, this bridges the expected failures and increases the availability of the system. Continuous operation is thus ensured.

The availability of a system determines production costs

An all-round reliable power supply system – consisting of high-quality power supply units, redundancy and buffer modules is a wise investment. The system can permanently reduce production costs during the operating phase and even pays for itself before the first failure.

This is because downtime costs include more than the lost profit due to a lower production output. Other additional costs, some obvious and some hidden, are almost impossible to prevent. For example, there may be increased personnel costs, due to the deployment of qualified service teams or the extra work required of the overall staff, to make up for the production downtime. Even smaller factories can quickly be affected by downtime costs of up to tens of thousands of euros.

Some basic components can only be kept in the machine for a short time, depending on the industry. If spare parts are not readily available, the costs of disposing of the raw materials or products and, if necessary, cleaning the machine are added to the costs of lost production. This is the case, for example, in the chemical and pharmaceutical industries or in food processing machinery.

One solution to reduce such downtime costs is to keep all spare parts immediately available in stock. Another option is to rely on a permanently available and reliable power supply system. Overall, the latter is more cost-effective.

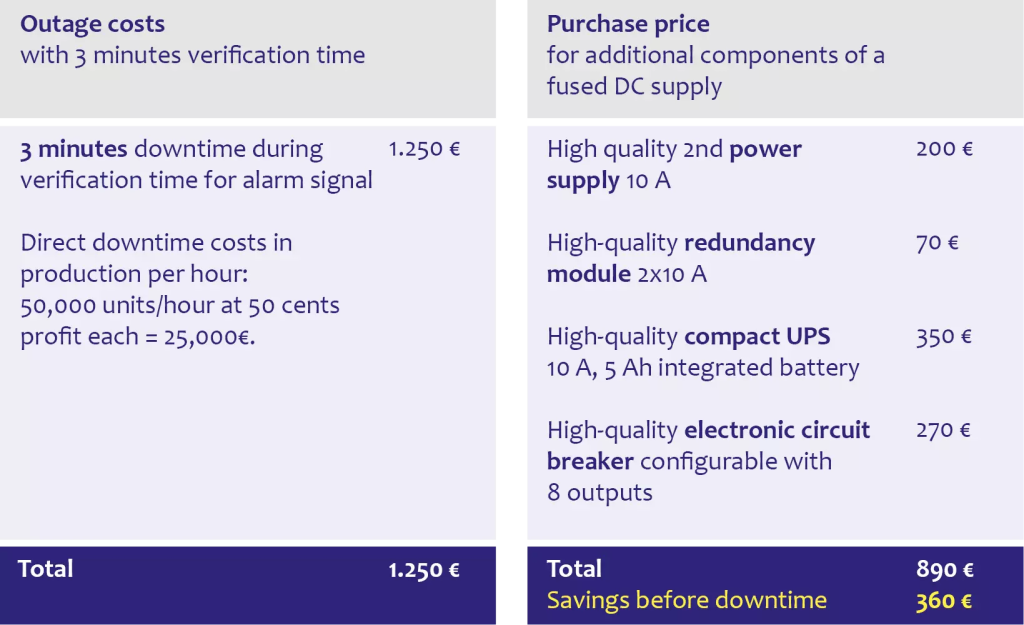

This can be illustrated with the help of a small rough calculation. Even in the first few minutes of a failure, which are required for the detection of the fault alone, the additional costs for an improved, constantly reliable DC power supply are exceeded by the direct failure costs.

Does a systems approach make more sense than stand-alone devices?

To increase the availability of a system, the focus should not only be on an individual power supply unit, but on the holistic power supply system, which is made up of safety-relevant components. This system solution pays off for the user in every phase of the system’s life and prevents high downtime costs.

https://products.pulspower.com/us/blog/post/how-can-the-availability-of-a-system-be-increased