Enthusiastic Response to A+T’s Ethernet-Based Instrument Systems

September 28, 2023

No one puts up with slow data connections in the home or office, why do so on board a yacht? As experts in improving system performance, A+T have seen an increasing number of super yachts and race boats moving towards an Ethernet based instrument systems because in our modern era information flow is expected to be fast and readily available. The current installed base of A+T Instruments includes over 500 of the largest and fastest boats on the planet and this is growing fast.

There are plenty of sailors who will support this, among them is Mark Stevens, previously skipper aboard the 170ft superyacht Red Dragon. With a complex network of instruments that includes five chart plotters and a large number of displays, this is a big boat with complex systems already installed. Like many, the process of migrating to A+T started with swapping out the processor and some of the displays.

‘It was a big decision to start using A+T. Having started the changeover I could not be happier,’ says Stevens. ‘They work seamlessly with our B&G and I was happy see the process of upgrade all over the yacht. This is a product that really works.’

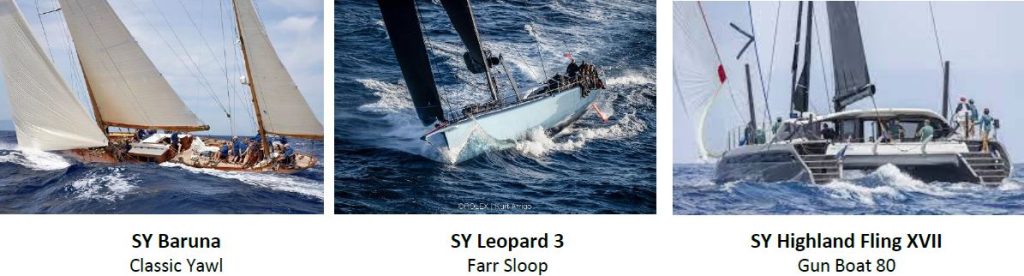

A selection of A+T’s Ethernet powered large performance yachts

A+T have developed a full instrument and autopilot system based on Ethernet linking all displays, processors and sensors. Ethernet offers very high speed, cable runs of up to 100m in length and no restrictions on system architecture. Most importantly, each connection is completely isolated so a damaged wire, switch or device will not take down the whole system. Power can be provided locally where needed and 24v is normally recommended on A+T systems, a voltage normal on most large yachts.

Technical muscle power is only part of the story. Global 24/7 support is at the heart of the A+T’s business. ‘The A+T team are regularly in Palma, Italy, mainland Spain and the south of France as well as at most major regattas, but our support goes well beyond this,’ Agnew says. ‘Delivering software changes and upgrades remotely to the ATP is a simple process using a browser on a laptop. In addition to this, we offer remote support through TeamViewer which allows us to look straight into the processor anywhere in the world. ‘So, taking this and the technical advantages into consideration, we believe that our ATP is way in front of other instrument systems.’