What Does Derating Mean for Power Supplies? And When Is It Necessary?

August 24, 2022

By Maximilian Hülsebusch, Global Product Marketing & Communications Manager, PULS Power

Derating is a protective measure which allows the use of power supplies at high temperatures, at high altitudes or in alternative mounting orientations. In this blog article you will learn what you should consider when it comes to derating.

Most power supply manufacturers specify ratings for lifetime, output current, and reliability (e.g. MTBF) for their products. However, this information only applies under certain environmental conditions. In particular, the temperature limits must be observed so that the components in the power supply do not overheat or wear out prematurely. A necessary means to regulate the temperature is the so-called derating.

What does derating mean?

Derating means the reduction of the output power depending on the ambient conditions. Derating is therefore a recommended protective measure for electronic components and devices to protect them from high temperatures and prevent failures. The power reduction is precisely specified for each power supply. The necessary procedure is described in the respective data sheet.

When is derating necessary for a power supply?

There are several environmental conditions that increase the temperature of the power supply and thus are a potential risk. These include high ambient temperatures, an installation altitude of more than 2,000 meters and mounting orientations that deviate from the recommended installation.

Notice

The power supplies do not regulate the derating automatically. You have to adapt the device to the ambient conditions of your application during installation. In this way you will avoid system downtimes and damage to the power supply itself.

You can find the specifications for the necessary settings for all PULS power supplies in the data sheets. The derating curves for adapting the output current depending on the temperature and the installation altitude are also very helpful.

Derating at high ambient temperatures

Nearly all industrial power supplies require derating above a certain ambient temperature in order to protect the electronics. Above a defined temperature limit, the output power must be reduced linearly. The corresponding value can be found in the data sheet. For example, the 960W (24V, 40A) power supply QS40.241 requires a derating of 24W/°C above 60°C. If you want to use the device near its temperature limit of 70°C, only a maximum of 720W would be advisable to maintain the life expectancy or (MTBF).

This value must be taken into account when selecting a power supply – especially if a device requires derating even at lower temperatures. Many competitive power supplies demand the reduction of the output power from 40°C, however, such temperatures are common in a closed control cabinet without a cooling system. System engineers basically have 4 options to solve this problem.

- 1. Choose a power supply that has a higher temperature limit before it requires derating.

- 2. Choose a power supply unit with a higher output power in order to have a sufficient power budget available despite derating.

- 3. Connect multiple identical power supplies in parallel to get the total power you need.

- 4. Install a cooling system.

All options mean higher investments within the planning phase of the system, but are usually worth it in terms of higher reliability and longer service life.

Even if the system is subsequently expanded, it must be checked whether the power supply can provide sufficient power reserves under the prevailing conditions.

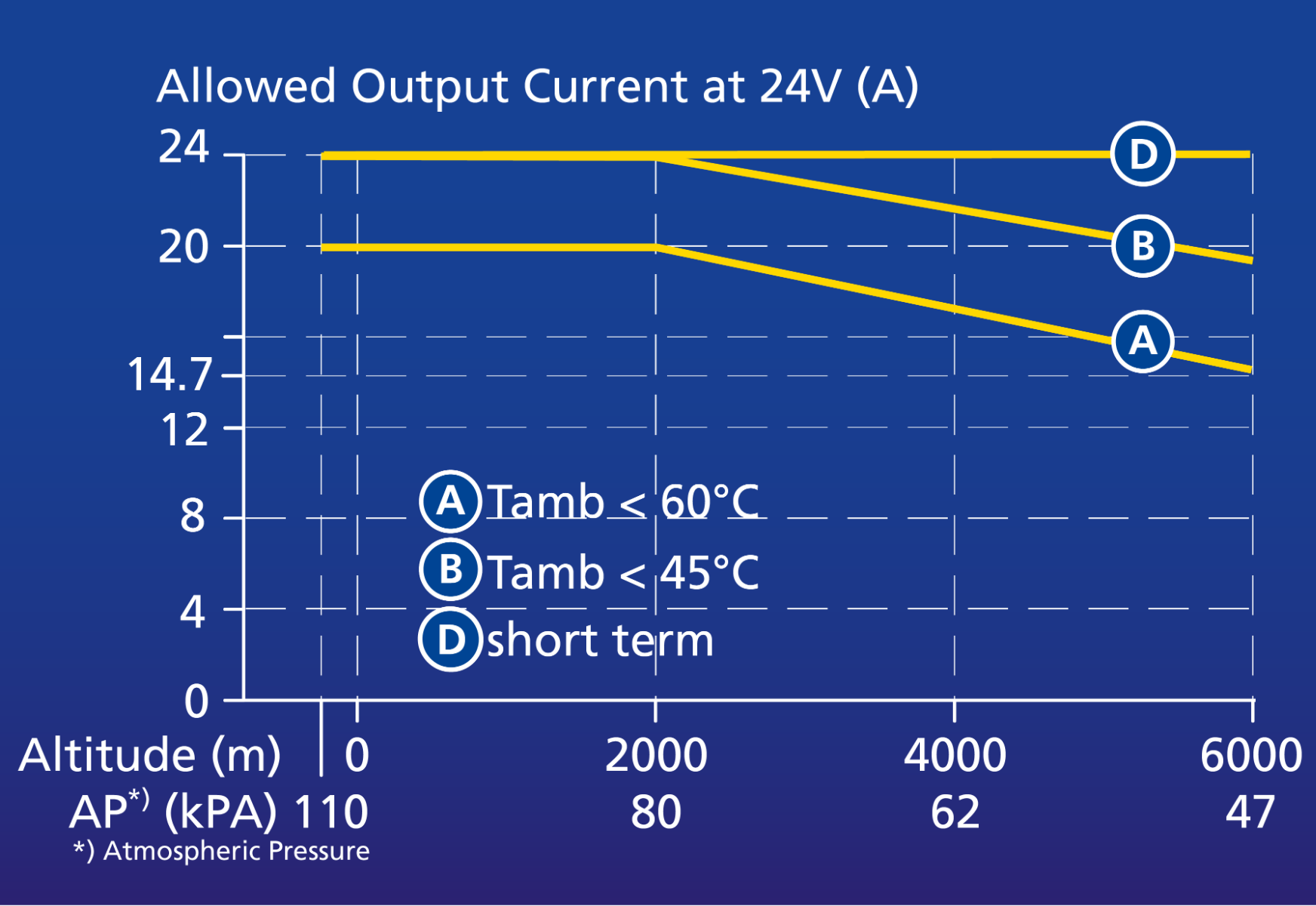

Derating at altitudes above 2,000 meters

Derating is also necessary at an installation altitude above 2,000 meters. With increasing altitude, the atmospheric pressure decreases. This means that the air density decreases, which also reduces the cooling effect of the convection air flow.

Accordingly, the output power must be reduced above 2,000 meters by a certain percentage per 1,000 meters or the ambient temperature must be lowered. The specified values for the necessary power derating vary depending on the power supply unit and can be found in every PULS data sheet in the chapter “Environment”.

As an alternative to the power reduction, a cooling system could be integrated in the control cabinet, which means that derating can be avoided.

Derating at alternative mounting orientations

If you need to mount the power supply in an orientation that deviates from the recommended standard installation, derating or limiting the ambient temperature is also necessary. The reason is the functionality of convection-cooled power supplies. The air flow inside the device cools the temperature-sensitive components, such as electrolytic capacitors, and the warm air is discharged to the outside. The recommended standard installation position is based on a “chimney effect”. The cool air enters the power supply at the lower ventilation grille, heats up due to the power losses of certain components and is discharged again on the top of the device.

In the development phase the devices are designed according to the cool design principles. Temperature-sensitive components that determine the lifetime are placed in the cool spots in the power supply. The developers position other components (e.g. transformers) that heat up most at the top of the power supply so that they do not heat up the other components. In addition, the PULS developers make sure that the air can always flow freely and is not blocked by components.

If the device is mounted upside down or e.g. on a table-top (see graphic 2-4), this affects the air flow. Without reducing the output power, the components could overheat, which has a negative impact on the lifetime and, in the worst case, can lead to a failure of the power supply.

Conclusion

Derating is necessary for almost all industrial power supplies above a certain temperature, installation altitude or in a deviating mounting orientation. With many manufacturers, however, you have to search for the corresponding specification in the data sheet for quite some time. PULS provides the necessary information for derating on the front page of its data sheets. In this way, system developers and technicians can see this important information at first glance and adapt the power supply perfectly to the ambient conditions during installation.

https://products.pulspower.com/us/blog/post/what-does-derating-mean-for-power-supplies