Decoding the Most Versatile Industrial Connector in the World

January 24, 2022

By Colin Cartwright, System Sales Manager, Murrelektronik

If you were around in 1980’s you will probably remember walkmans, vcrs, mix tapes and big hair bands on MTV, amongst other things. The decade started with the release of PacMan, the Rubiks Cube and a Hollywood actor called Ronald Reagan winning the US Presidential election. It ended with the first episode of the Simpsons, Timothy Berners-Lee inventing the World Wide Web and the Berlin Wall coming down to symbolize the end of the Cold War.

Some notable 1980’s inventions included the first artificial heart, CD players, the Apple MacIntosh computer, Microsoft Windows, the Nintendo Gameboy and the first GPS satellite to be launched into space.

But there was one more invention of the 1980s that wasn’t really noticed by the general public, but ultimately paved the way for fast, easy and reliable electrical connections that we often take for granted in control systems today. We are talking about the M12 circular connector that was launched at the Hannover Fair in 1985 and has since become one of the most popular industrial connectors in the world.

These days, you will be hard-pressed to walk into any manufacturing plant without seeing an M12 connector. They are used to connect sensors to I/O modules, vision systems to Ethernet switches, light curtains to safety controllers and much more. Originally only available in 3-pole and 4-pole versions with an A-Coded keyway for power and I/O signals, the M12 connector is still evolving and has become one of the most versatile circular connectors available.

Now, more than 35 years since it was launched, there are many different types of M12 connectors for signal, data and power connections. With M12 connectors now capable of carrying up to 16A of power and transmitting data at speeds up to 10 Gbit/s, that quick connect M12 connector invented in 1985 has truly become one of the most versatile industrial connectors of the world!

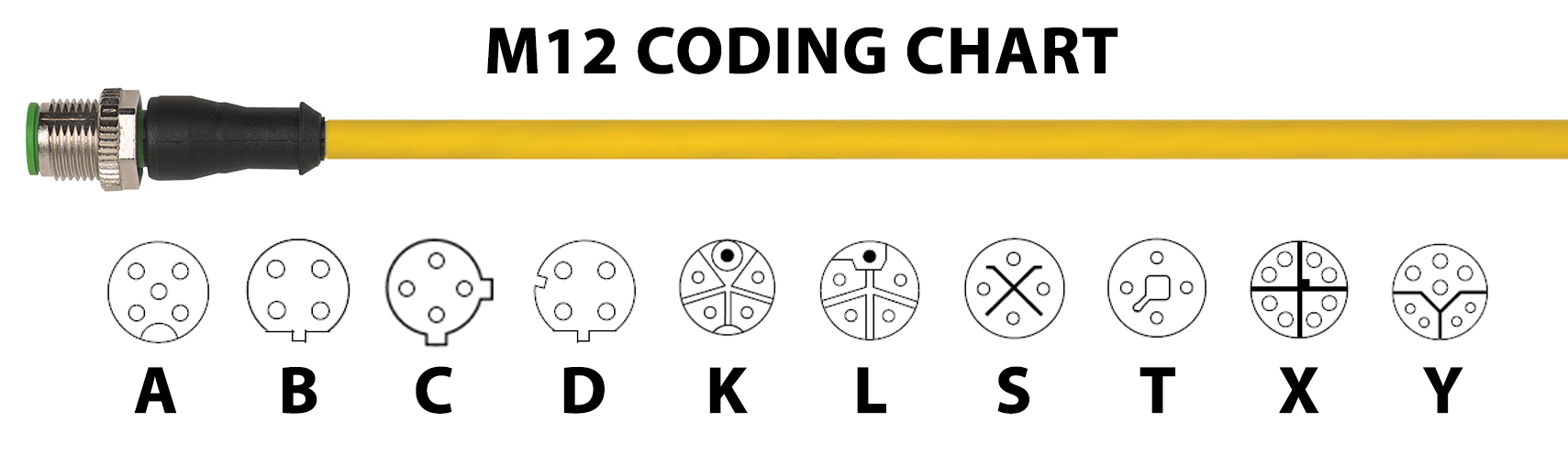

In addition to being relatively small and providing an IP67 protection rating (when tightened correctly), one of main the reasons that the M12 connector has been so successful comes down to the coded keyways that help prevent accidental cross connecting of different signal types. Some M12 connectors are designed specifically for data and some are designed for power, so you really do not want to get them mixed up. The coded keyways are extremely effective at preventing this from happening.

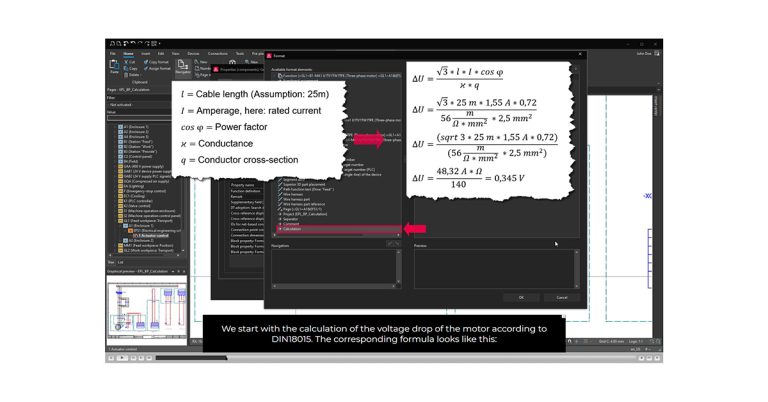

There are currently more than a dozen types of M12 connector coding that are identified with an alphabetic letter ranging from A to Y (there is no Z yet). With so many different options available, it can be a little confusing to choose the right type of M12 cable / connector for your application. Here at Murrelektronik we often get asked which coding works for a specific type of connection, so in this month’s edition of Connectivity Corner I thought it would be a good idea to decode some of the main types of M12 connector that are currently available.

To keep things simple, I will focus on the male side of the connectors and use “poles” to describe the electrical contacts, but rest assured the female versions of the connectors have contacts with the same ratings as the male connectors. We’ll cover the ten most popular M12 connectors in alphabetical order first, then summarize these by application at the end. Let’s get started with the letter “A”.

A-Coded connectors are the original and the most common M12 connector. Available with 3 to 17 poles, they are mostly used for signals and DC power (up to 4A depending on the number of poles) and some data applications. A-Coded connectors are often found on sensors, actuators, safety devices and I/O modules. You will also find many IO-Link devices using M12 A-Coded connectors with Class A devices using 3 poles and Class B devices using 5 poles.

B-Coded connectors with 2, 4 or 5 poles are more commonly found in Europe because they are mainly used on Profibus and Interbus fieldbus systems. Although B-Coded connectors are not very common here in North America, you can still run into them from time-to-time if you end up working on older Siemens PLCs or other control systems that were originally designed in Europe.

C-Coded connectors are another less common M12 connector type. These 3 to 6 pole connectors are usually found on 120VAC powered sensors and actuators so you will likely only find them on older machines with AC control systems. The connector incorporates a dual keyway which prevents them from being accidentally connected to an M12 A-Coded connector.

D-Coded connectors are currently one of the most common M12 connectors used for connecting field devices to industrial networks. You will find these 4-pole M12 connectors standard on Ethernet, ProfiNet and EtherCat field devices and industrial CAT5e cables that have a maximum data transfer rate of up to 100 Mbit/s. If you are looking for Gigabit data transfer rates and CAT6 rated cables you will need an X-Coded connector (see below).

K-Coded connectors are the first of four relatively new M12 connectors designed for power transmission. K-Coded connectors have 5 poles (4+PE) and are rated up to 630VAC/DC with a maximum of 12A per pole but are not very common yet.

L-Coded connectors are probably the most popular of the newer M12 power connectors. Designed to provide DC power with high current, you will find them replacing the traditional 7/8” power connectors on many of the newer I/O modules that are being released. L-Coded M12 connectors are available with 4 poles or 5 poles (4+PE) with a current rating of up to 16A per pole and a maximum voltage rating of 63VAC/DC.

S-Coded connectors have very similar specifications to K-coded M12 connectors but are only available with 3-pole (2+PE) or 4-pole (3+PE) versions. With a rated voltage up to 630VAC and a maximum current of 12A per pole, they are a good choice for AC power connections.

T-Coded connectors are another M12 connector designed for DC power connections. This 4-pole connector is rated up to 63VDC/AC, with each pole rated to 12A. The lower current rating and the lack of a PE option are key differences between this and the L-coded connector.

X-Coded connectors were designed to meet the high-speed demands of modern industrial networks. Capable of data transmission rates of up to 10 Gbit/s they are easy to identify due to the galvanic separation plates that isolate the wire pairs forming an X. This 8-pole M12 connector is quickly becoming the standard connector for high-speed industrial network connections that require IP67 protection.

Y-Coded connectors are another relatively new type of connector designed to provide a hybrid solution for connecting power and data using a single cable. The connector consists of 8 poles split into two groups of 4 that are galvanically separated with a metal coding that looks like a Y. The metal coding plates also provide an effective separation between power and data. The connector’s data poles are rated at 0.5A and can transmit data up to 100Mbit/s. The power poles rated to 6A at 30 VDC.

That’s a lot of M12 codings to digest! Let’s try to make it a little easier by categorizing them by application and the four most common M12 connectors we work with every day at Murrelektronik.

Power & I/O Signal Connections

A-Coded connectors with 3 to 5 poles are definitely the most common type of M12 connector. They are mostly used to provide power (4A max) and signal connections for sensors, pneumatic or hydraulic valves, IO-Link devices and many other 24VDC devices.

Networking & Data Connections

D-Coded connectors with 4 poles are often used to connect field devices like I/O modules, VFDs and valve manifolds to an Ethernet, Profinet or Ethercat network up to 100 Mbit/s.

X-Coded connectors with 8 poles are used to connect newer, faster field devices like vision systems, scanners and high-speed actuators to networks capable transferring data up to 10 Gbit/s.

DC Power Transmission

L-Coded connectors with 4 or 5 poles are fast becoming the new standard for power connectors. While smaller than traditional 7/8” connectors, L-Coded connectors are capable carrying more current (16A) which enables more power for high current applications and also enables more devices to be connected on a single power cable run.

That covers the four main types of M12 connector you will come across. What about those other six M12 connector types?

Well, we rarely work on Profibus or Interbus applications anymore, so B-Coded connectors are not something we run into often here in Canada and it’s been more 10 years since I’ve worked on an AC application requiring a C-Coded connector so that leaves the K, S, T and Y coded connectors. These four connectors are still relatively new and have not yet been widely integrated into many industrial devices yet, so as of spring 2021, we are not seeing any real demand for these types of connectors. That’s not to say you will not come across devices using them, or their popularity will not increase in the near future but it’s just good to know about them.

With its proven reliability, compact size, IP67 (and IP69K) protection, multiple contact options, and a current rating of up to 16A, the M12 connector is probably the most versatile industrial connector in the world, and I suspect it will remain that way for many more years.

Until next month, have fun decoding all those M12 connectors out there and if you need help choosing the right connector for your device or application, don’t hesitate to reach out to us here at Murrelektronik Canada.

For more information, visit www.murrinc.com/us/.