Do You Know Your First Step When Choosing a Cabinet Cooler?

January 3, 2022

When cooling an electrical enclosure, the airflow is an important factor to consider. However, to add to the complexity, different cooling products use air differently.Here is a “must know” concept to ensure success for your application. In order to make this distinction, it’s important to know the difference between open and closed-loop cooling, and why one system may be the better option for a specific application:

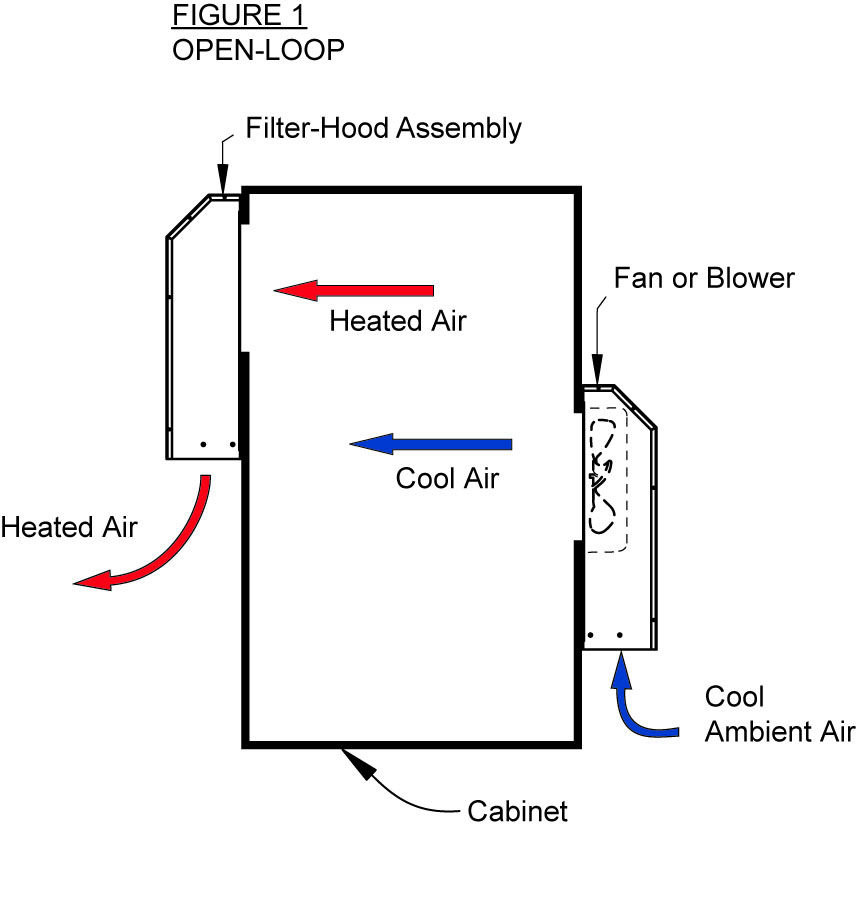

OPEN-LOOP cooling describes a process that replaces the air inside a chamber with “fresh” cooler air from outside the chamber. Open-loop cooling is the most commonly used process when the available air supply is cool enough and clean enough to provide the required heat removal. Open-loop ventilation uses ambient air to remove the heat, and may consist of small muffin-type fans that exhaust or supply an electrical cabinet, with optional filters to prevent airborne aerosols and dust from entering the cabinet. Fans have the advantage of utilizing a minimum amount of cabinet space and will move a substantial volume of air where flow is virtually unimpeded. Cost and complexity is minimized with this type of ventilation process. Where density of components impedes airflow, packaged blowers or motorized impellers may be arranged to operate against these higher static pressures. With a rack enclosure, supplemental fan trays may be used to spot cool or supplement other air-moving devices.See Fig 1.

cabinet space and will move a substantial volume of air where flow is virtually unimpeded. Cost and complexity is minimized with this type of ventilation process. Where density of components impedes airflow, packaged blowers or motorized impellers may be arranged to operate against these higher static pressures. With a rack enclosure, supplemental fan trays may be used to spot cool or supplement other air-moving devices.See Fig 1.

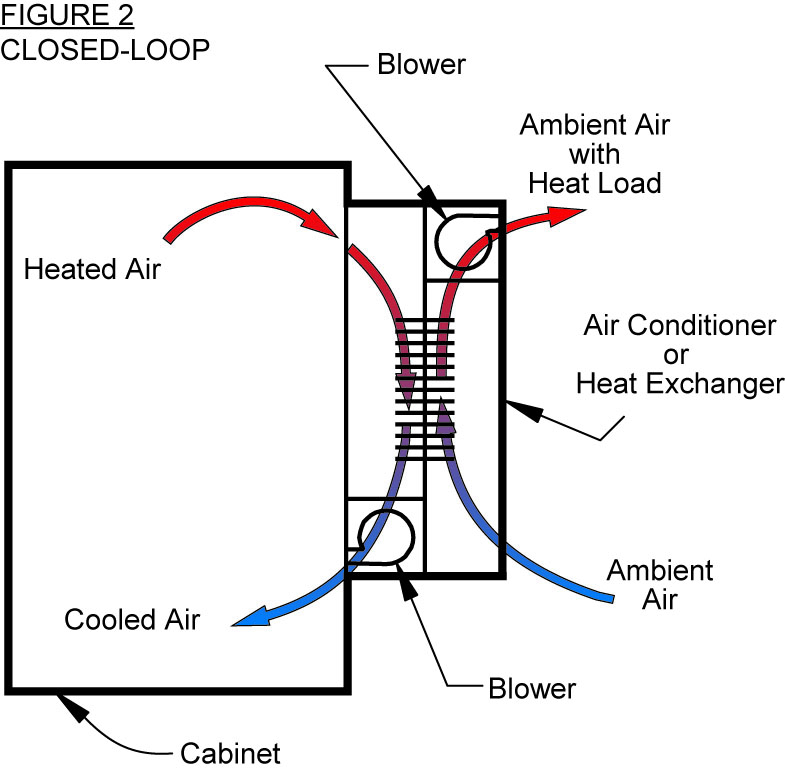

CLOSED-LOOP cooling describes a process that reconditions (reuses) the air inside an enclosure. Air conditioners and heat exchangers are examples of cooling products that use a closed loop. The purpose of this system is to prevent contaminated air from entering and causing damage to critical components, and when maximum internal cabinet temperatures cannot be maintained using open-loop ambient air cooling, closed-loop systems are used to satisfy this requirement. If the ambient air is hostile, containing dirt, oil, humidity or corrosives, this will adversely affect the performance or ultimate longevity of the components. Many applications using intricate electronic/electrical components require a closed-loop cooling system to dissipate heat buildup without introducing outside contaminated air. Air-to-air heat exchangers, water-to-air  heat exchangers and air conditioning units are great options to cool a confined amount of air within an enclosure. Air conditioners have the added ability to maintain a temperature lower than ambient and reduce the humidity within the controlled space.See Fig 2.and watch the video.

heat exchangers and air conditioning units are great options to cool a confined amount of air within an enclosure. Air conditioners have the added ability to maintain a temperature lower than ambient and reduce the humidity within the controlled space.See Fig 2.and watch the video.

{videobox}ERNTzKc7ODU{/videobox}

In harsh environments involving high temperatures, heavy particulates, oil or chemicals capable of damaging components, ambient air must be kept out of the enclosure. Sealed enclosures are generally used, with closed-loop cooling consisting of two separate circulation systems in a single unit. One system, sealed against the ambient air, cools and recirculates the clean cool air throughout the enclosure. The second system uses ambient air or water to remove and discharge the heat.

![]()